Bio-based flame-retardant polyether polyol and preparation method thereof

A flame-retardant polyether and polyol technology, applied in the field of bio-based flame-retardant polyether polyol and its preparation, can solve the problems of easy dissociation, poor combination of bio-based materials and polyols, and reduced flame-retardant performance question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The invention provides a bio-based flame-retardant polyether polyol, which comprises: 9.20% of ethylene glycol, 18.40% of diethylene glycol, 18.40% of propylene glycol, 9.20% of dipropylene glycol, 18.40% of Butanediol, 0.45% nano magnesium hydroxide, 0.32% nano cerium oxide, 0.25% nano tin antimony oxide, and the rest is corn starch;

[0027] The weight of the ethylene glycol, the diethylene glycol, the propylene glycol, the dipropylene glycol and the butanediol is in a ratio of 1:2:2:1:2;

[0028] The present invention also provides a preparation method of bio-based flame-retardant polyether polyol, the specific preparation steps are as follows:

[0029] Step 1: weighing ethylene glycol, diethylene glycol, propylene glycol, dipropylene glycol, butanediol, nano magnesium hydroxide, nano cerium oxide, nano tin antimony oxide and cornstarch according to the above weight percentage;

[0030] Step 2: Mix 1 / 2 weight portion of nano-magnesium hydroxide in step 1 with 1 / 4 we...

Embodiment 2

[0038] Different from Example 1, it includes: 10.30% ethylene glycol, 20.60% diethylene glycol, 20.60% propylene glycol, 10.30% dipropylene glycol, 20.60% butanediol, 0.75% Nano magnesium hydroxide, 0.42% nano cerium oxide, 0.39% nano tin antimony oxide, and the rest are corn starch.

Embodiment 3

[0040] All different from Examples 1-2, it includes: 9.75% ethylene glycol, 19.50% diethylene glycol, 19.50% propylene glycol, 9.75% dipropylene glycol, 19.50% butanediol, 0.60% nano magnesium hydroxide, 0.37% nano cerium oxide, 0.32% nano tin antimony oxide, and the rest is corn starch.

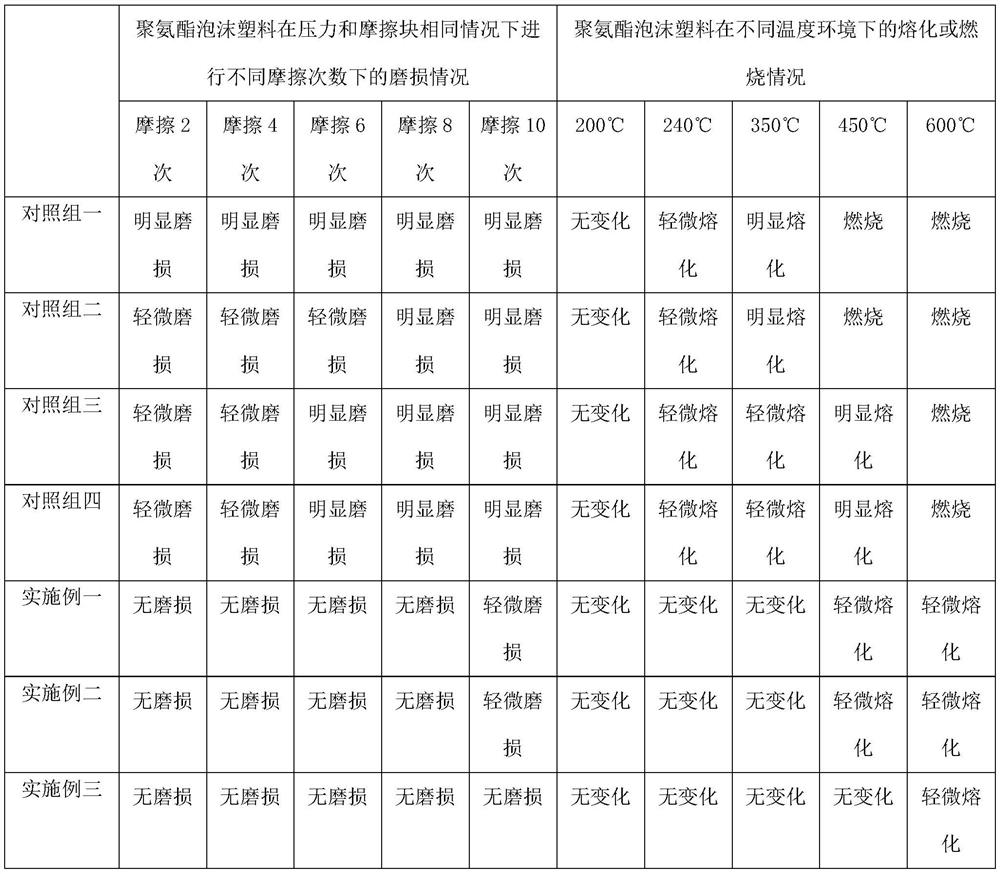

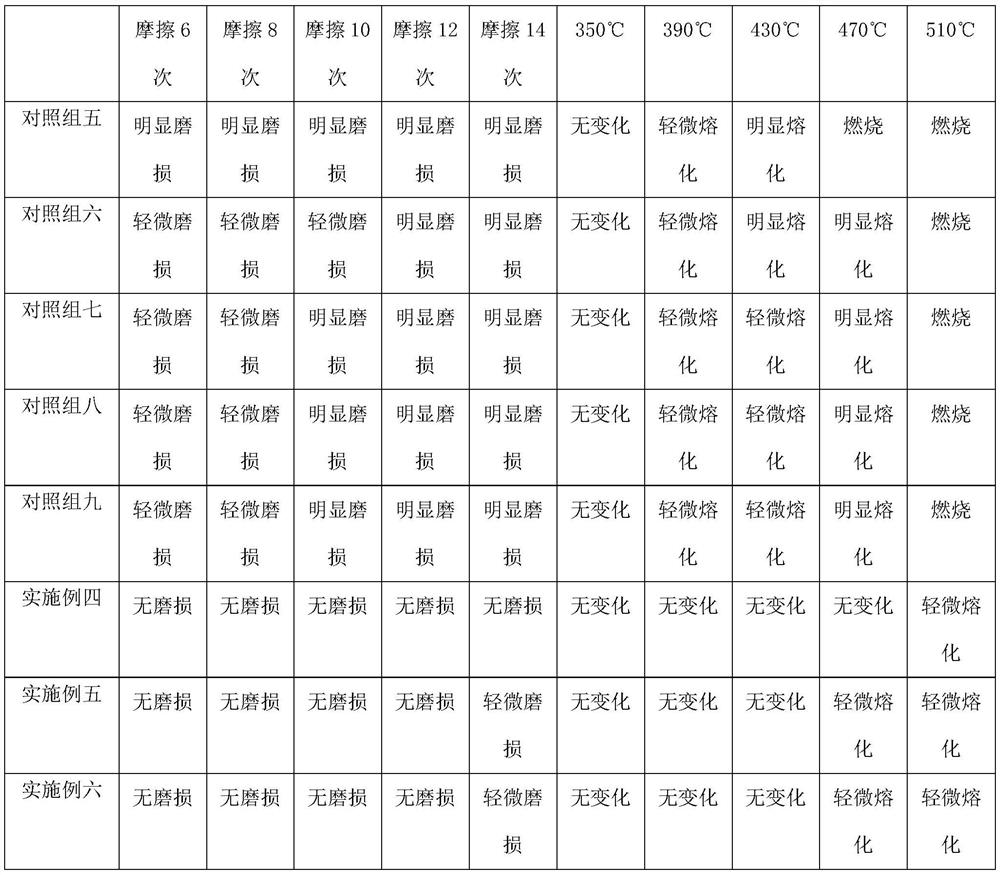

[0041] Take the bio-based flame-retardant polyether polyol prepared in the above-mentioned Examples 1-3 and the bio-based flame-retardant polyether polyol of the control group 1, the bio-based flame-retardant polyether polyol of the control group 2, and the bio-based flame-retardant polyether polyol of the control group 3 respectively. The bio-based flame-retardant polyether polyol and the bio-based flame-retardant polyether polyol of the control group 4 were tested, and the bio-based flame-retardant polyether polyol of the control group 1 was a common bio-based flame-retardant polyether polyol on the market , the bio-based flame-retardant polyether polyol of the control group two is compare...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com