Cross-linked hydrogel for muscle stem cell culture as well as preparation method and application of cross-linked hydrogel

A technology for stem cell culture and cross-linked hydrogel, which is applied in the field of preparation of new enzymatic-physical method double-cross-linked network hydrogel, can solve the problems of strong adhesion of muscle stem cells and short retention time of growth factors, and achieve improved Effect of high biocompatibility and mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

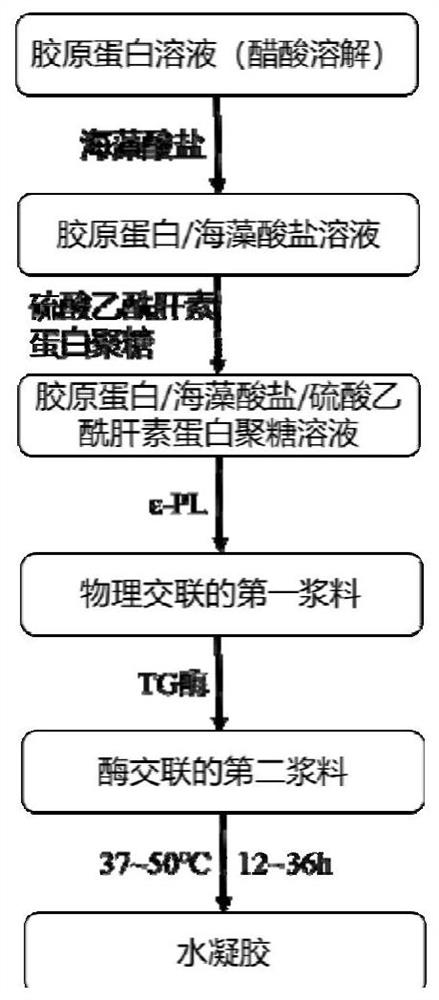

[0048] Example 1: Preparation of Enzymatic-Physical Double Network Hydrogel of Collagen / ε-PL / Heparan Sulfate Proteoglycan / Alginate

[0049] according to figure 1 Preparation of hydrogel: Add 10 g of collagen to 100 mL of 0.02 mol / L acetic acid solution, stir and dissolve to obtain a collagen solution. Add 15g of alginate to the collagen solution, stir until the alginate solution is obtained to obtain a collagen / alginate solution; then add 20 μg of heparan sulfate proteoglycan to the prepared solution to obtain a collagen / alginate / heparan sulfate proteoglycan solution; add the ε-PL whose molar ratio of amino group and carboxyl group in the alginate is 1:1 to the solution, stir evenly to obtain the first slurry prepared by physical cross-linking; Add 0.1 g of TG enzyme to the slurry, and stir evenly to obtain the second slurry prepared by enzyme crosslinking. The slurry was put into a mold, cross-linked at 37°C for 12 hours, and demolded to obtain an enzymatic-physical double n...

Embodiment 2

[0050] Example 2: Preparation of Enzymatic-Physical Double Network Hydrogel of Collagen / ε-PL / Heparan Sulfate Proteoglycan / Alginate

[0051] according to figure 1 Preparation of hydrogel: Add 15 g of collagen to 100 mL of 0.05 mol / L acetic acid solution, stir and dissolve to obtain a collagen solution. Add 25g of alginate to the collagen solution, stir until the alginate solution is obtained to obtain a collagen / alginate solution; then add 50 μg of heparan sulfate proteoglycan to the prepared solution to obtain a collagen / alginate / heparan sulfate proteoglycan solution; add the ε-PL whose molar ratio of amino group and carboxyl group in the alginate is 2:1 to the solution, stir evenly to obtain the first slurry prepared by physical cross-linking; Add 1.5 g of TG enzyme into the slurry, stir evenly, and obtain the second slurry prepared by enzyme crosslinking. The slurry was put into a mold, cross-linked at 37°C for 36 hours, and demolded to obtain an enzymatic-physical double...

Embodiment 3

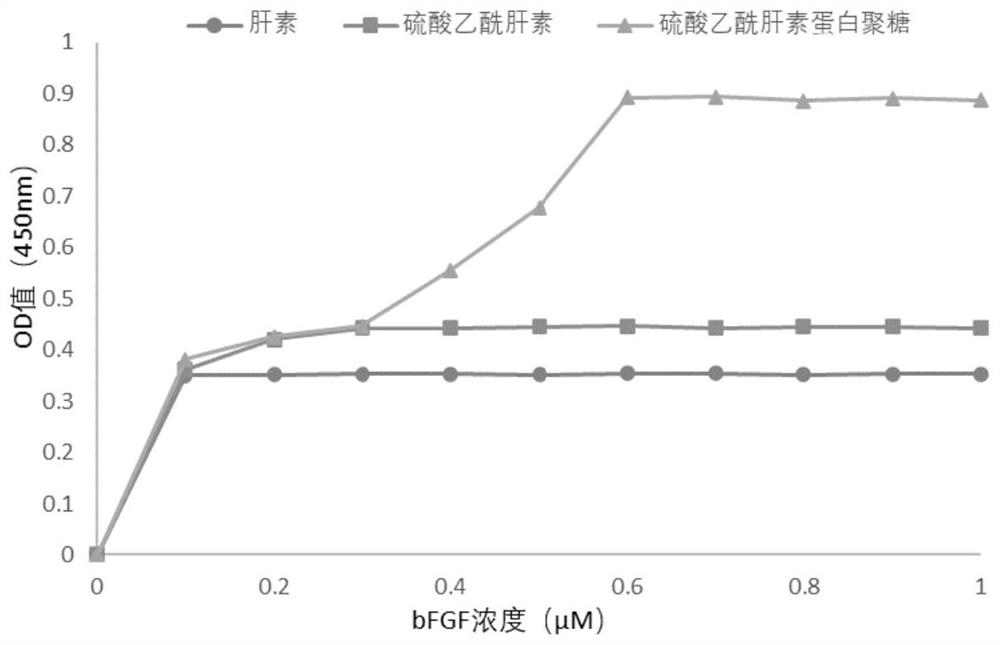

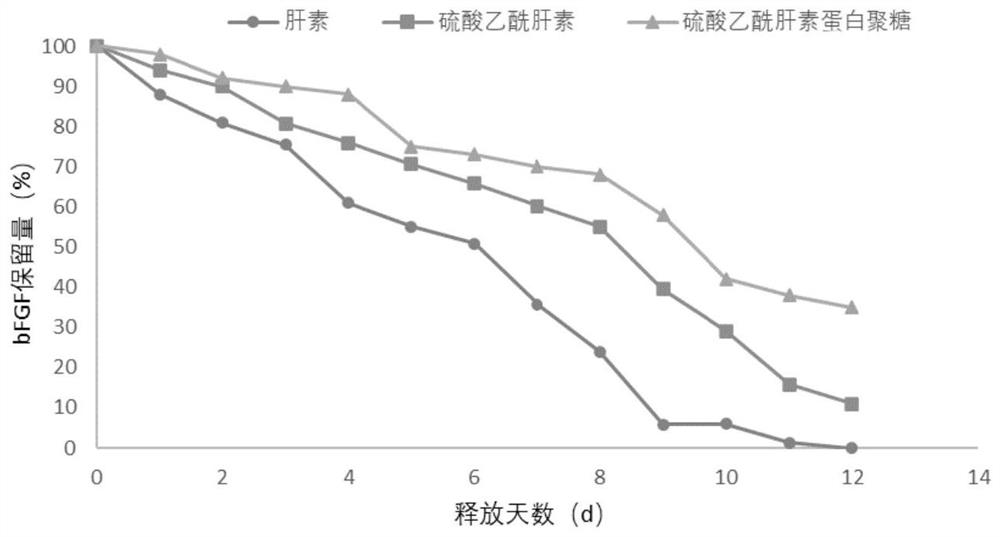

[0052] Example 3: Adsorption of Hydrogel Growth Factors

[0053] Adsorption experiment of growth factors: wash the enzymatically-physically cross-linked double network hydrogel (the hydrogel of Example 1 and Example 2) with PBS, and soak the obtained hydrogel in 75% ethanol for 20 Minutes, followed by repeated immersion in sterile deionized water for 5 minutes, the operation of washing ethanol with sterile water was carried out three times to remove all residual ethanol (FoodHydrocolloids, 2017, 72, 210-218), and then the hydrogel was transferred to a cell containing growth In the solution of factor vitamin C (0.05μg / mL) and bFGF (10ng / mL), it was obtained after swelling for 24 hours. Finally, the content of bFGF (450nm) and vitamin C (536nm) in the remaining solution was detected by enzyme-linked immunosorbent assay (ELISA), and the effect of hydrogel on growth was calculated according to the difference between the initial concentration of bFGF and vitamin C in the solution a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com