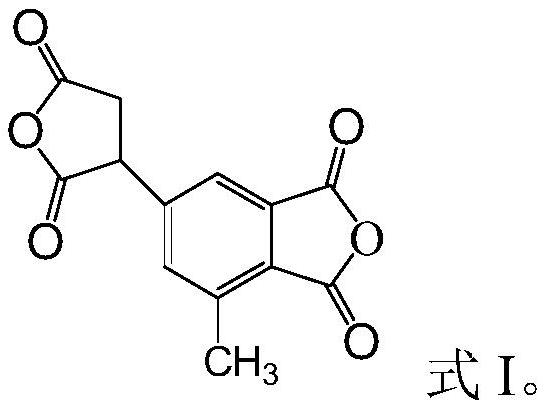

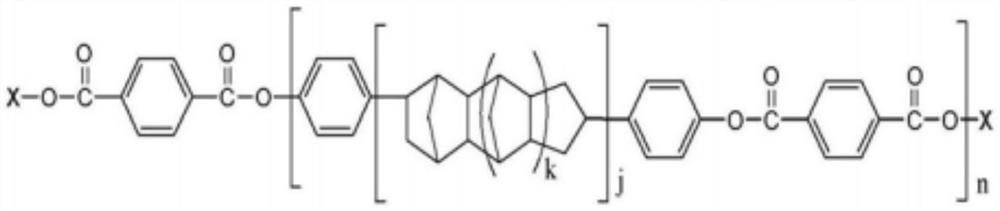

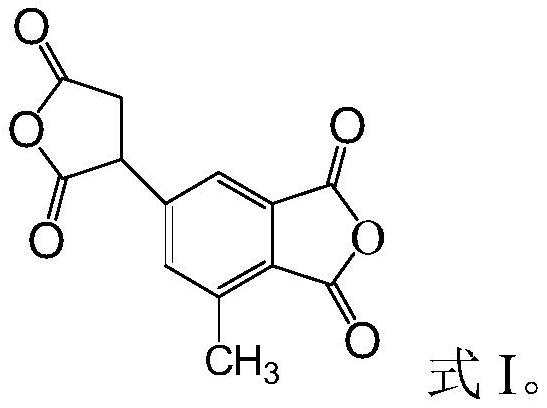

Halogen-free flame-retardant resin composition and application thereof

A technology of flame-retardant resin and resin composition, which is applied in the field of copper clad laminates, and can solve problems such as poor heat resistance and reduced process yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-8、 comparative example 1-8

[0100] The above-mentioned examples and comparative examples each provide a halogen-free flame-retardant resin composition (see Table 1 for details of the formulas of the examples, and Table 2 for details of the formulas of the comparative examples, and the unit is parts by weight) and a copper-clad laminate, and the specific preparation method as follows:

[0101] (1) Mix the components in the formulation amount of the halogen-free flame-retardant resin composition uniformly in a mixed solvent of methyl ethyl ketone and DMF, and disperse uniformly at room temperature to obtain a resin glue with a solid content of 65%;

[0102] (2) Use the reinforcing material (glass fiber cloth) to impregnate the resin glue obtained in step (1), place it in a 160°C oven and bake for 5 minutes to achieve curing to obtain a prepreg; place the prepreg on two copper The foils are laminated and cured for 2 hours in a hot press at 210° C. and 2.1 MPa pressure to obtain the copper clad laminate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tg | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com