A kind of NdFeB magnet composite coating and preparation method thereof

A composite coating and NdFeB technology, which is applied in the manufacture of permanent magnets, inductors/transformers/magnets, electrical components, etc., can solve problems affecting the corrosion resistance of magnets, affecting the service life of magnets, and destroying the integrity of coatings, etc., to achieve Excellent binding force, high production efficiency, and strong environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0079] A composite coating is prepared on the surface of the pretreated NdFeB product, and the preparation process is as follows:

[0080] The first step is to electrodeposit nickel on the surface of the pretreated NdFeB product: the composition of the nickel plating solution is NiSO 4 ·6H 2 O350g / L, NiCl 2·6H 2 O 50g / L, H 3 BO 3 45g / L, sulfonamide 5ml / L, 1,4-butynediol 1ml / L, sodium lauryl sulfate 2ml / L;

[0081] Dk (cathode current density) range is 1.0-1.2A / dm 2 ;

[0082] In the second step, after the nickel plating is completed, the NdFeB product with the nickel layer on the surface is washed twice with water;

[0083] The third step, interlayer activation: after the second step of water washing is completed, the nickel-plated NdFeB product is subjected to interlayer activation, and the interlayer activation is the same as the activation process in the above-mentioned pretreatment;

[0084] The fourth step, after the third step is completed, wash the product twic...

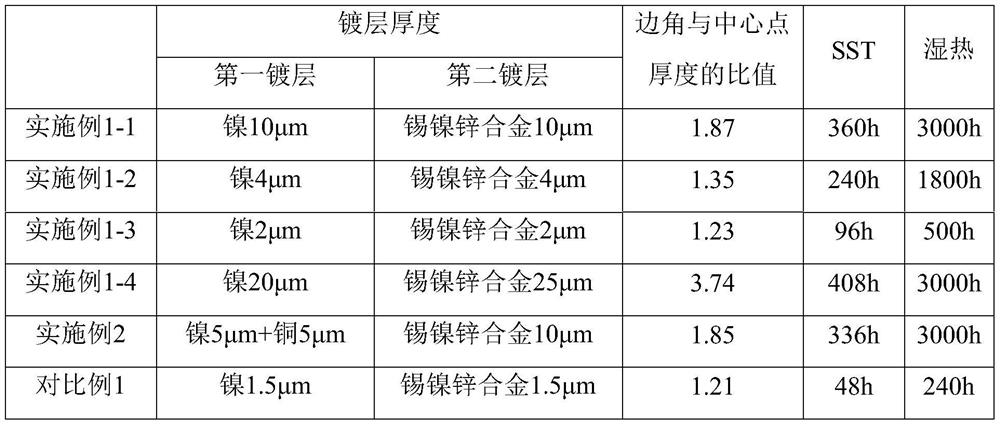

Embodiment 1-1

[0091] After the preparation process in Example 1, the total thickness of the nickel-tin-nickel-zinc composite coating obtained was 20 μm, wherein the thickness of the nickel layer was 10 μm, and the thickness of the tin-nickel-zinc ternary alloy layer was 10 μm. Among them, the current densities for preparing the nickel layer and the tin-nickel-zinc layer are both 1.0-1.2A / dm 2 , the nickel layer electrodeposition time is 60min, and the tin-nickel-zinc layer electrodeposition time is 55min.

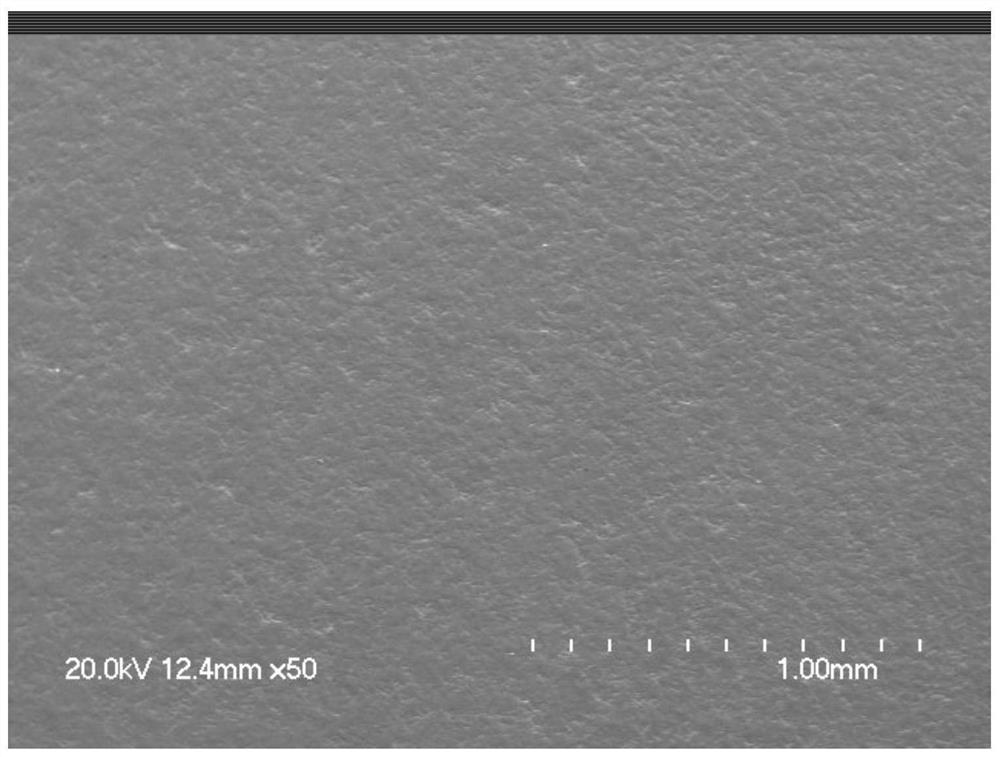

[0092] like figure 1 As shown, the surface of the nickel-tin-nickel-zinc composite coating is flat and dense.

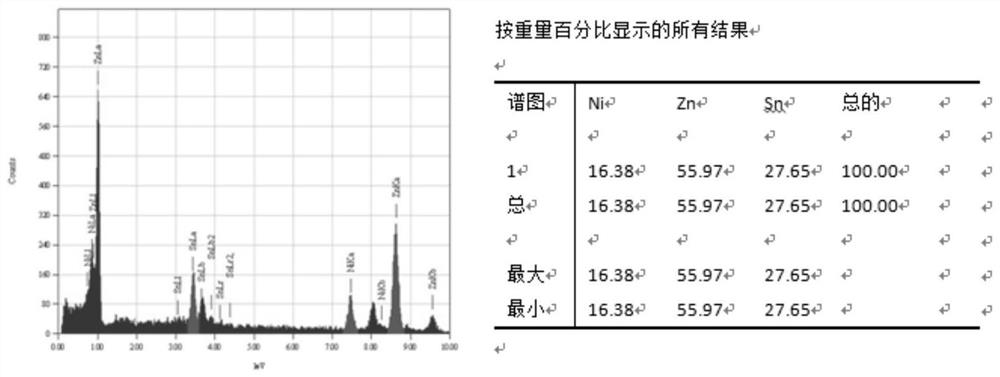

[0093] like figure 2 As shown, in the tin-nickel-zinc ternary alloy layer, the content of Ni element is 16.38 wt %, the content of Zn element is 55.97 wt %, and the content of Sn element is 27.65 wt %.

Embodiment 1-2

[0095] After the preparation process in Example 1, the total thickness of the nickel-tin-nickel-zinc composite coating obtained is 8 μm, wherein the thickness of the nickel layer is 4 μm, and the thickness of the tin-nickel-zinc ternary alloy layer is 4 μm. Among them, the current densities for preparing the nickel layer and the tin-nickel-zinc layer are both 1.0-1.2A / dm 2 , the nickel layer electrodeposition time is 25min, and the tin-nickel-zinc layer electrodeposition time is 20min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com