High-quality SiC single crystal preparation device and method

A preparation device and high-quality technology, applied in the direction of single crystal growth, single crystal growth, chemical instruments and methods, etc., can solve the problems of insufficient uniform growth, poor quality of SiC single crystal, and thickness that does not meet the market demand.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

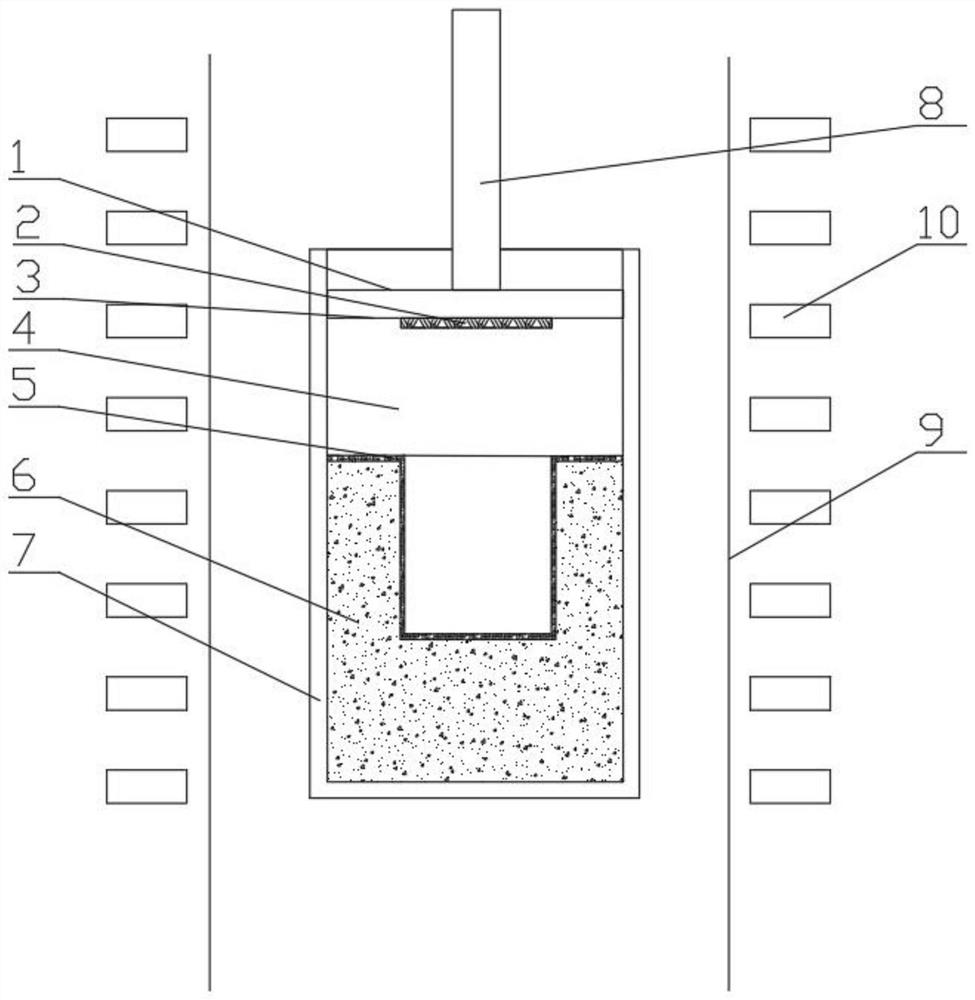

[0040] Specific implementation mode one: combine Figure 1-Figure 9 Describe this embodiment, a high-quality SiC single crystal preparation device of this embodiment, including an upper cover 1, a seed crystal 2, a lower cover 3, a crucible main body 4, a filter screen 5, an insulating body 7, a power rod 8, and a quartz tube 9 and a heating coil 10, a filter screen 5 is placed in the crucible main body 4, a lower cover 3 and an upper cover 1 are arranged on the upper part of the crucible main body 4, the lower cover 3 is located on the lower side of the upper cover 1, and the lower side of the lower cover 3 is bonded with seeds Crystal 2, the upper side of the upper cover 1 is connected to the power rod 8, the outer wall of the crucible main body 4 is covered with an insulating body 7, the crucible main body 4 is placed inside the quartz tube 9, and a heating coil 10 is installed outside the quartz tube 9;

[0041] Four lower sliders 302 are processed in a circumferential arr...

specific Embodiment approach 2

[0043] Specific implementation mode two: combination Figure 1-Figure 6 Describe this embodiment, a high-quality SiC single crystal preparation device of this embodiment, the crucible main body 4 is fixed in the quartz tube 9 through the inner bracket 12;

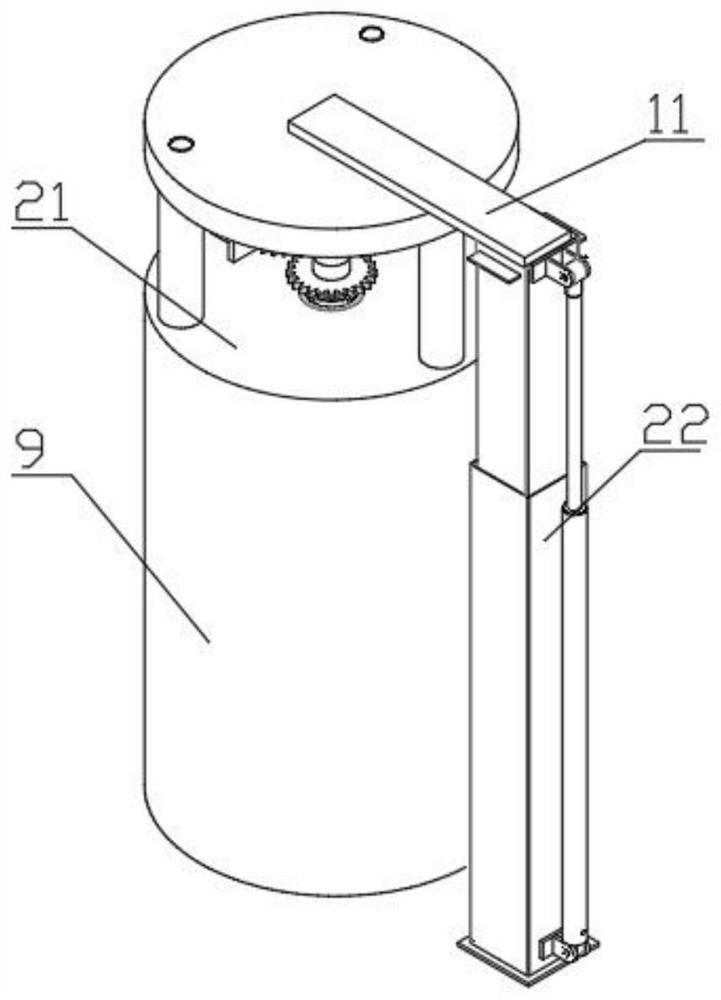

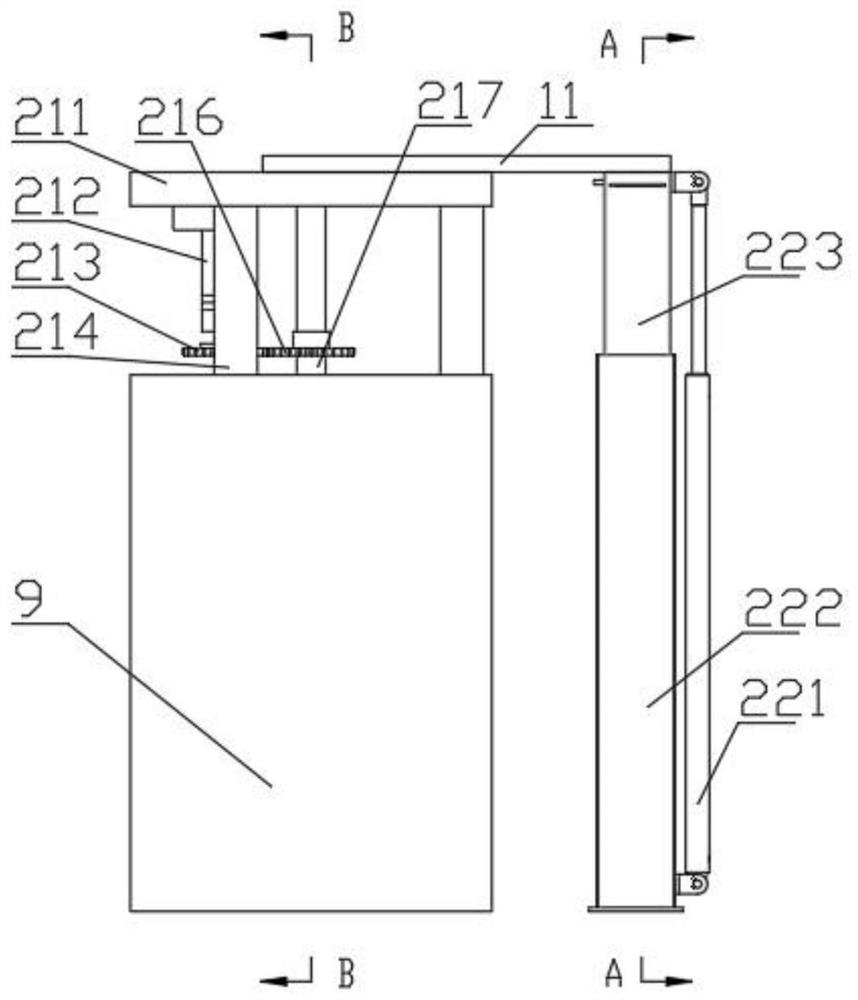

[0044]It also includes a rotating mechanism 21, a lifting mechanism 22 and a connecting frame 11, and the rotating mechanism 21 and the lifting mechanism 22 are connected by the connecting frame 11;

[0045] The rotating mechanism 21 includes an upper frame 211, a motor 212, a driving gear 213, a connecting rod 214, a lower frame 215, a driven gear 216 and a drive shaft 217, and the upper frame 211 and the lower frame 215 are arranged through three circular arrays of connecting rods. 214 connection, the upper frame 211 is fixedly connected with the motor 212, the output end of the motor 212 is connected with the driving gear 213, the lower frame 215 is connected with the driving shaft 217 through the bearing, the driving sh...

specific Embodiment approach 3

[0048] Specific implementation mode three: combination figure 2 Describe this embodiment, a high-quality SiC single crystal preparation device of this embodiment, the outer sleeve 222 and the inner telescopic arm 223 are both square.

[0049] Specific implementation mode four: combination figure 1 , Figure 9 Describe this embodiment, a high-quality SiC single crystal preparation device of this embodiment, the filter screen 5 is a cylindrical barrel with an annular plate installed at the open end, the filter screen 5 is a graphite filter screen, the raw material 6 is a silicon carbide raw material, and the raw material 6 is fixed by a graphite filter, which can effectively prevent carbon particles from rising with the gas during purification and crystal growth, and prevent carbon particles from adhering to the surface of the seed crystal to form carbon inclusions. The stopper 102 is a graphite stopper.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com