Method for improving bonding strength of low-emissivity coating and carbon fiber base material

A low-emissivity coating and carbon fiber substrate technology, which is applied in the fields of carbon fiber, fiber treatment, textiles and paper making, can solve the problems of low-emissivity coating and substrate bond strength reduction, poor mechanical properties, and difficult experimental operations And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

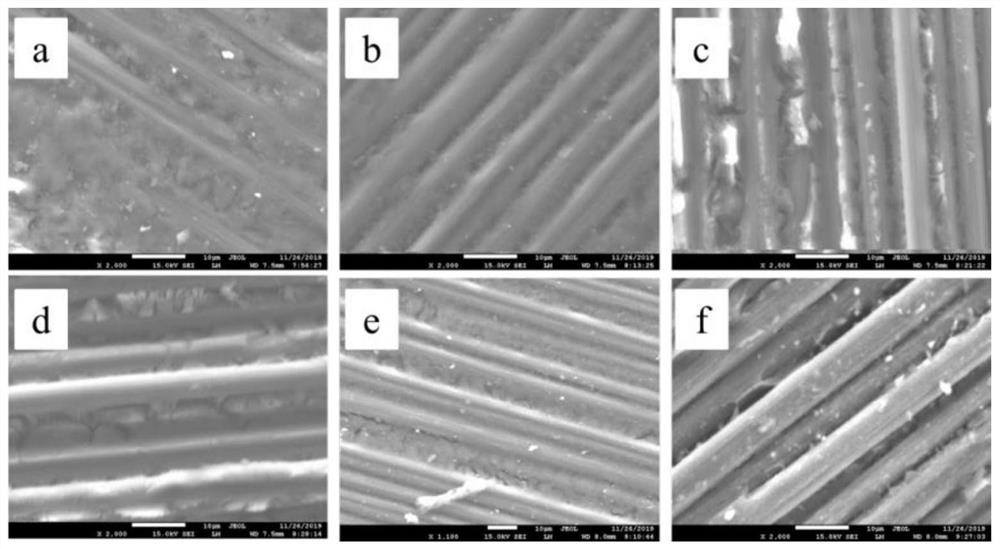

[0050] S1: Cleaning the surface of the polyimide-based carbon fiber substrate with an organic solvent;

[0051] S2: Prepare a layer of 5-10 μm silicone resin on the surface of the polyimide-based carbon fiber substrate. After the surface is dry, place it at 200°C and cure for 4 hours to obtain the pretreated polyimide-based carbon fiber substrate;

[0052] S3: Take 60g of organic solvent, add 30g of silicone resin and 30g of flake aluminum powder, stir and disperse at a speed of 600r / min for 10min to obtain a coating;

[0053] S4: Prepare the prepared coating on the pretreated polyimide-based carbon fiber substrate, and then place it at room temperature for 6 hours. After it is surface-dried, cure it at 200°C for 4 hours to obtain a coating thickness of 50~ 60 μm sample.

[0054] Wherein, the organic solvent includes ethyl acetate and butyl acetate, and the mass ratio of ethyl acetate and butyl acetate is 2:1.

Embodiment 2

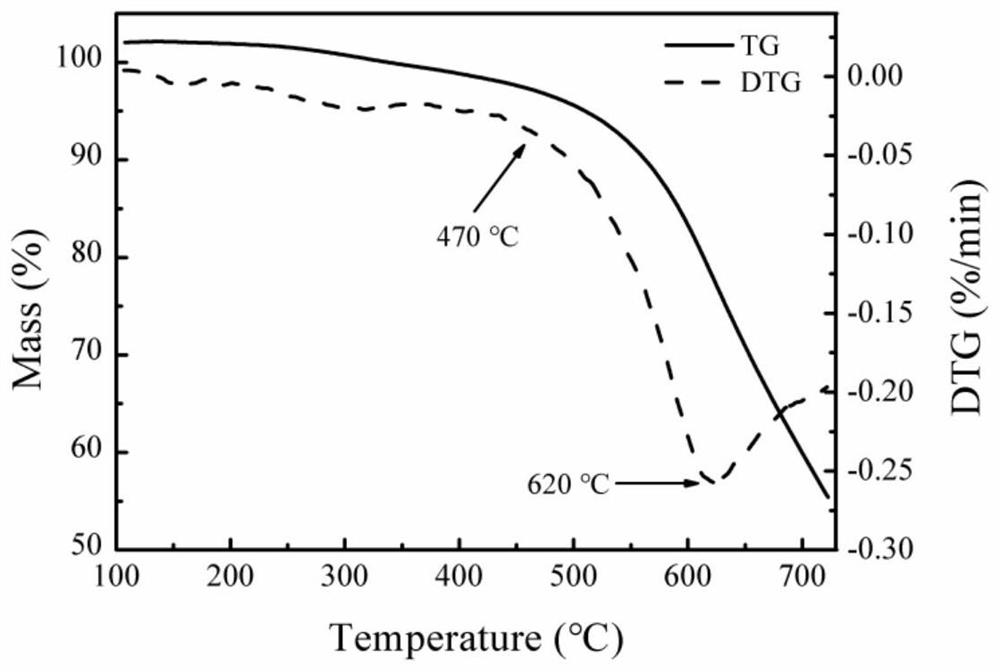

[0056] S1: heat-treat the polyimide-based carbon fiber substrate in a high-temperature muffle furnace at 500°C for 2 minutes;

[0057] S2: using an organic solvent to clean the surface of the polyimide-based carbon fiber substrate;

[0058] S3: Prepare a layer of 5-10 μm silicone resin on the surface of the polyimide-based carbon fiber substrate. After the surface is dry, place it at 200°C and cure for 4 hours to obtain the pretreated polyimide-based carbon fiber substrate;

[0059] S4: Take 60g of organic solvent, add 30g of silicone resin and 30g of flake aluminum powder, stir and disperse at a speed of 600r / min for 10min to obtain a coating;

[0060] S5: Prepare the prepared coating on the pretreated polyimide-based carbon fiber substrate, and then place it at room temperature for 6 hours. After it is surface-dried, cure it at 200°C for 4 hours to obtain a coating thickness of 50~ 60 μm sample.

[0061] Wherein, the organic solvent includes ethyl acetate and butyl acetat...

Embodiment 3

[0063] S1: heat-treat the polyimide-based carbon fiber substrate in a high-temperature muffle furnace at 500°C for 4 minutes;

[0064] S2: using an organic solvent to clean the surface of the polyimide-based carbon fiber substrate;

[0065] S3: Prepare a layer of 5-10 μm silicone resin on the surface of the polyimide-based carbon fiber substrate. After the surface is dry, place it at 200°C and cure for 4 hours to obtain the pretreated polyimide-based carbon fiber substrate;

[0066] S4: Take 60g of organic solvent, add 30g of silicone resin and 30g of flake aluminum powder, stir and disperse at a speed of 600r / min for 10min to obtain a coating;

[0067] S5: Prepare the prepared coating on the pretreated polyimide-based carbon fiber substrate, and then place it at room temperature for 6 hours. After it is surface-dried, cure it at 200°C for 4 hours to obtain a coating thickness of 50~ 60 μm sample.

[0068] Wherein, the organic solvent includes ethyl acetate and butyl acetat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Heat resistance temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com