A three-layer co-extruded antibacterial pp-r water supply pipe and preparation method thereof

A PP-R, three-layer co-extrusion technology, used in pipes, rigid pipes, mechanical equipment, etc., can solve the problems of easy reduction of inorganic antibacterial agents and poor stability of organic antibacterial agents, so as to reduce the precipitation of inorganic ions and improve the antibacterial properties. Impact performance, good impact stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

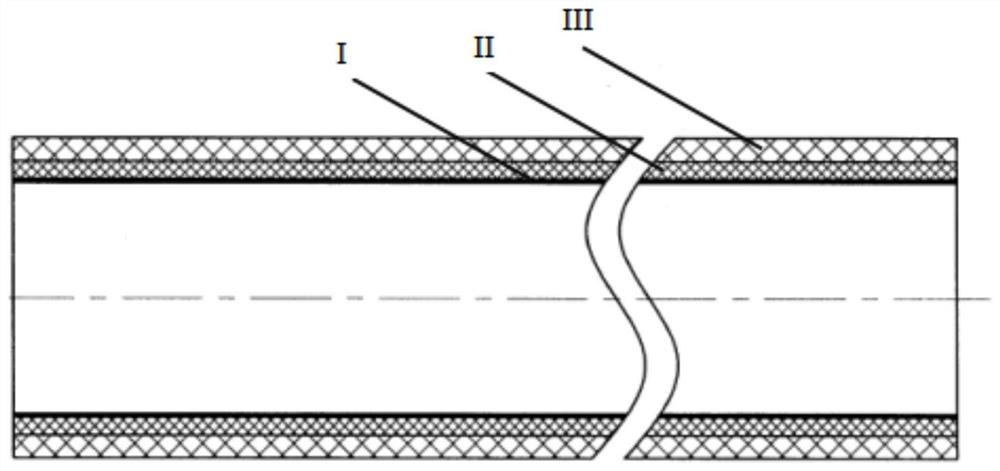

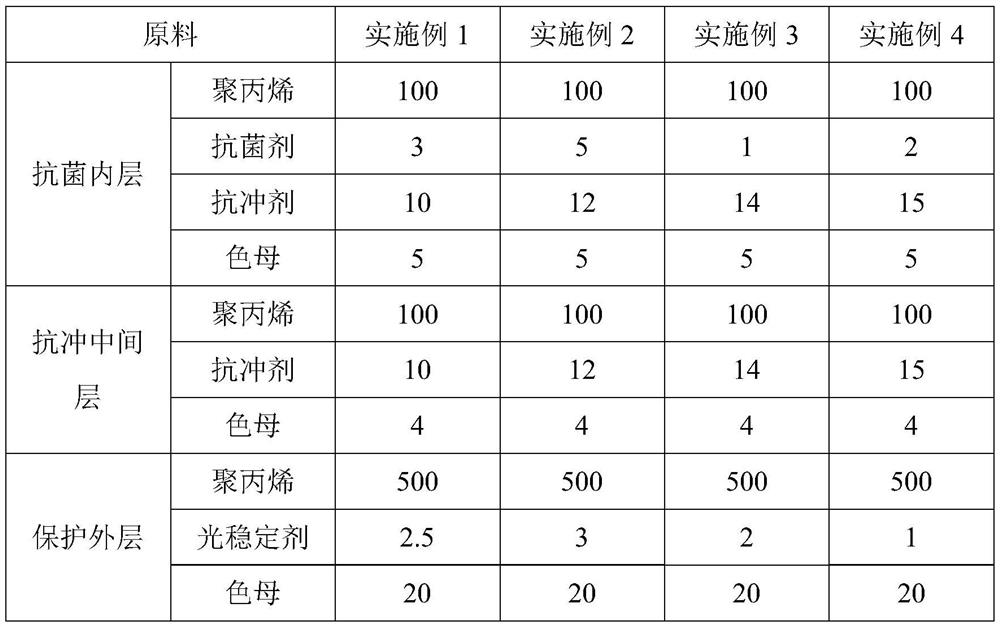

[0027] Embodiments 1-4 A kind of three-layer co-extruded antibacterial PP-R water supply pipe

[0028] The three-layer co-extruded antibacterial PP-R water supply pipe is made of raw materials in Table 1 and parts by weight thereof:

[0029] Table 1 Embodiment 1~4 three-layer co-extruded antibacterial PP-R water supply pipe raw material and parts by weight

[0030]

[0031] Preparation:

[0032] Stir and mix the raw materials of the antibacterial inner layer, impact-resistant middle layer and protective outer layer in the barrel respectively for 2 minutes. Using a three-layer co-extrusion die, the main extruder extrudes the impact-resistant middle layer, and the first co-extrusion The auxiliary machine extrudes the antibacterial inner layer, the second co-extrusion auxiliary machine extrudes the protective outer layer, and the third co-extrusion auxiliary machine extrudes the color stripes. Under the condition of 195-210°C, the compound co-extrusion is carried out, and the...

experiment example 1

[0033] Experimental example 1 Effect of anti-scouring agent on anti-scouring property of water supply pipe

[0034] Referring to Example 1, three-layer co-extruded antibacterial PP-R water supply pipe samples were prepared by using different amounts of anti-shock agents. With reference to the national standard GB / T 18743-2002, the test conditions were changed to a more stringent test temperature of -5°C. The hammer energy is 15J, and the anti-shock performance of the water supply pipe sample is measured, and the results are shown in Table 1.

[0035] Table 1 Effect of anti-scourrence agent on the anti-scourability of water supply pipes

[0036] serial number Anti-impact agent (parts) Impact resistance (damage rate%) 1 5 5 2 7 2 3 10 0 4 13 0 5 15 0

[0037] It can be seen from Table 1 that when the amount of anti-impact agent added is 10-15 parts, the damage rate is 0%, and the impact resistance is better; based on the purpose o...

experiment example 2

[0038] Experimental example 2 Effect of antibacterial agent on antibacterial and hygienic performance of water supply pipe

[0039] With reference to Example 1, three layers of co-extruded antibacterial PP-R water supply pipe templates were prepared using different amounts of antibacterial agents, and the antibacterial performance (with reference to the national standard GB / T 31402-2015) and hygienic performance (with reference to the national standard GB) of the water supply pipe samples were measured. / T 17219-2001), see Table 2 for the results.

[0040] Table 2 The effect of antibacterial agents on the antibacterial and hygienic properties of water supply pipes

[0041] serial number Antibacterial agent (parts) Antibacterial (%) Sanitation (Ag content mg / L) 1 1 90 <0.005

[0042] It can be seen from Table 2 that when the amount of antibacterial agent added is 1 to 5 parts, the antibacterial performance reaches 99%, and the silver content of the hygien...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com