Flexible lithium-sulfur battery positive electrode material, and preparation method and application thereof

A technology for lithium-sulfur batteries and cathode materials, which can be used in electrode manufacturing, battery electrodes, active material electrodes, etc., and can solve problems such as poor conductivity and storage performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

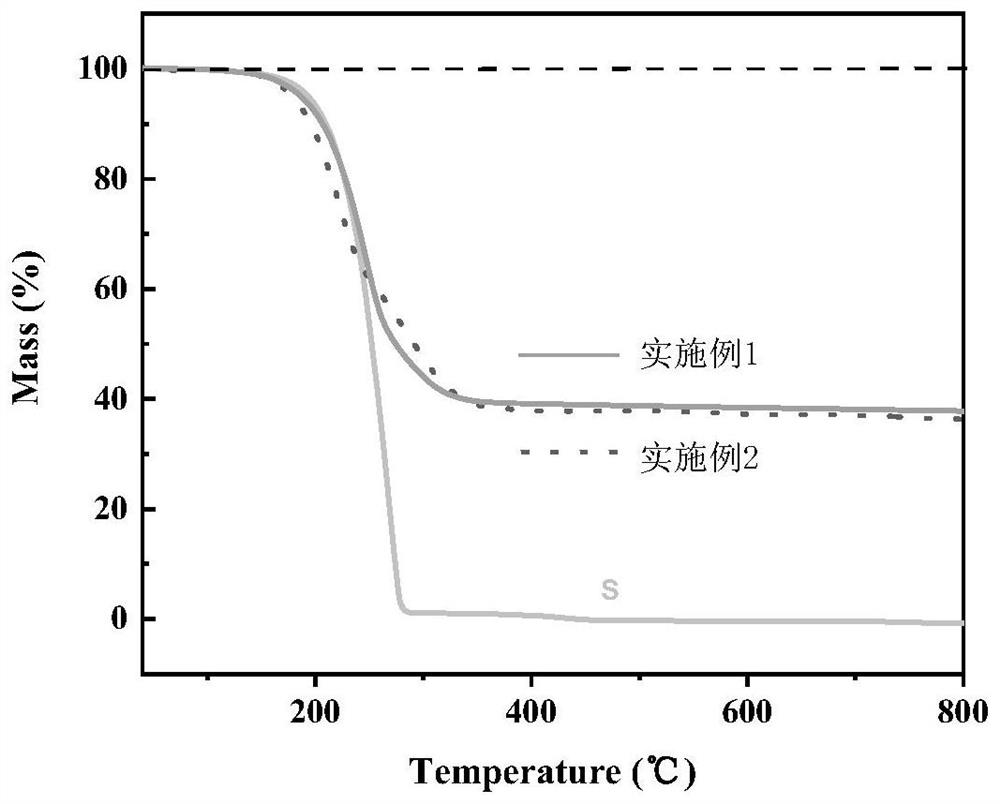

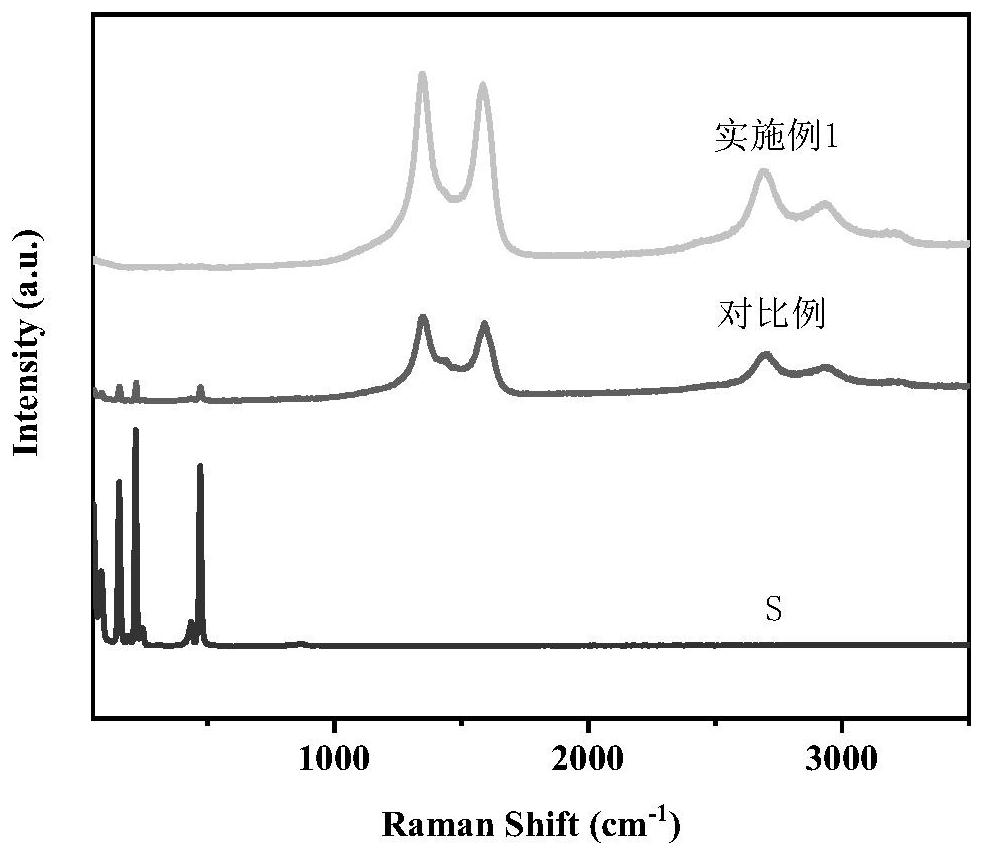

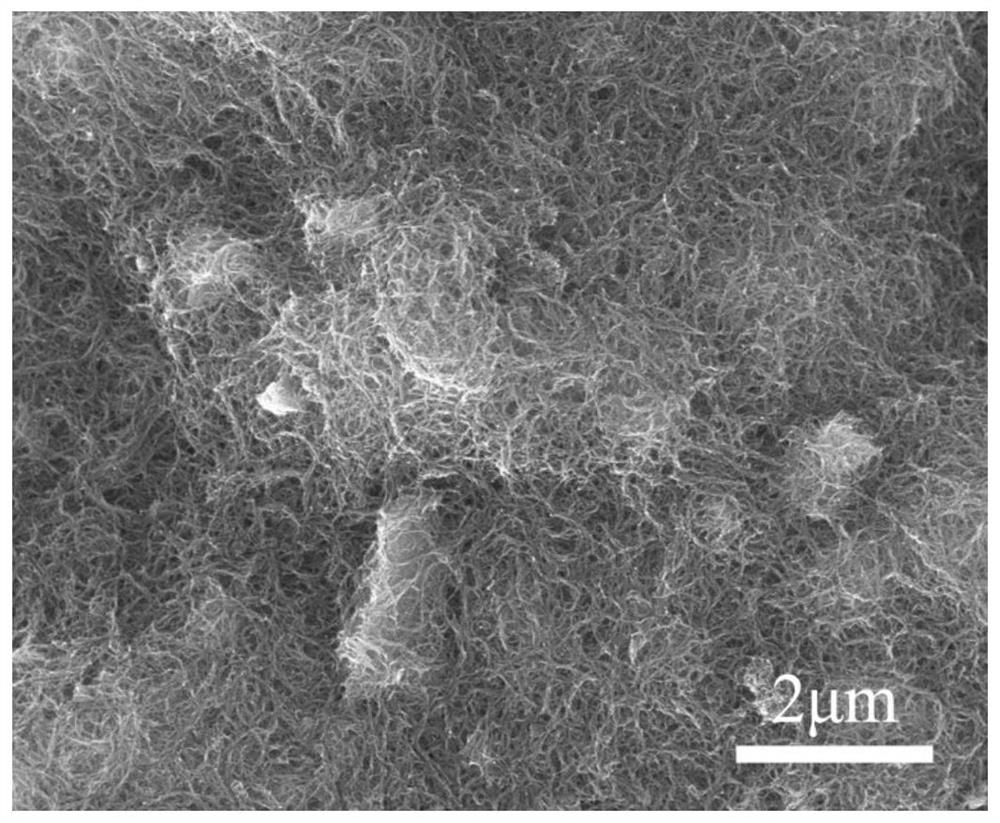

Embodiment 1

[0067] This embodiment provides a method for preparing a cathode material for a lithium-sulfur battery.

[0068] First, stir 0.63g of nano-sulfur in 120mL of acetone at room temperature for 30min, so that the sulfur reaches the dissolution-precipitation equilibrium, and obtain a sulfur-containing suspension; then add 0.07g of porous carbon (YP80) into the suspension, and disperse with 100Hz ultrasonic for 30min After 300 minutes at room temperature until the acetone is completely volatilized, 100 mL of deionized water and 0.3 g of carbon nanotubes (CNTs) are added thereto, ultrasonic dispersion is continued for 30 minutes, and flexible films and flexible positive electrode materials are obtained by suction filtration.

Embodiment 2

[0070] This embodiment provides a method for preparing a cathode material for a lithium-sulfur battery.

[0071] First, stir 0.64g of nano-sulfur in 120mL of acetone at room temperature for 30min, so that the sulfur reaches the dissolution-precipitation equilibrium, and obtain a sulfur-containing suspension; then add 0.16g of porous carbon (YP80) into the suspension, and disperse with 100Hz ultrasonic for 30min After 300 minutes at room temperature until the acetone is completely volatilized, 100 mL of deionized water and 0.2 g of carbon nanotubes (CNTs) are added thereto, ultrasonic dispersion is continued for 30 minutes, and flexible films and flexible positive electrode materials are obtained by suction filtration.

Embodiment 3

[0073] This embodiment provides a method for preparing a cathode material for a lithium-sulfur battery.

[0074] First, stir 0.56g of nano-sulfur in 120mL of acetone at room temperature for 30min, so that the sulfur reaches the dissolution-precipitation equilibrium, and obtain a sulfur-containing suspension; then add 0.14g of porous carbon (YP80) into the suspension, and disperse with 100Hz ultrasonic for 30min After 300 minutes at room temperature until the acetone is completely volatilized, 100 mL of deionized water and 0.3 g of carbon nanotubes (CNTs) are added thereto, ultrasonic dispersion is continued for 30 minutes, and flexible films and flexible positive electrode materials are obtained by suction filtration.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com