White laser light source generation device and method

A white light laser and generation device technology, applied in the direction of lasers, laser components, phonon exciters, etc., can solve the problems of white light laser light source generation, achieve high conversion efficiency, high nonlinear conversion rate, and simple manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

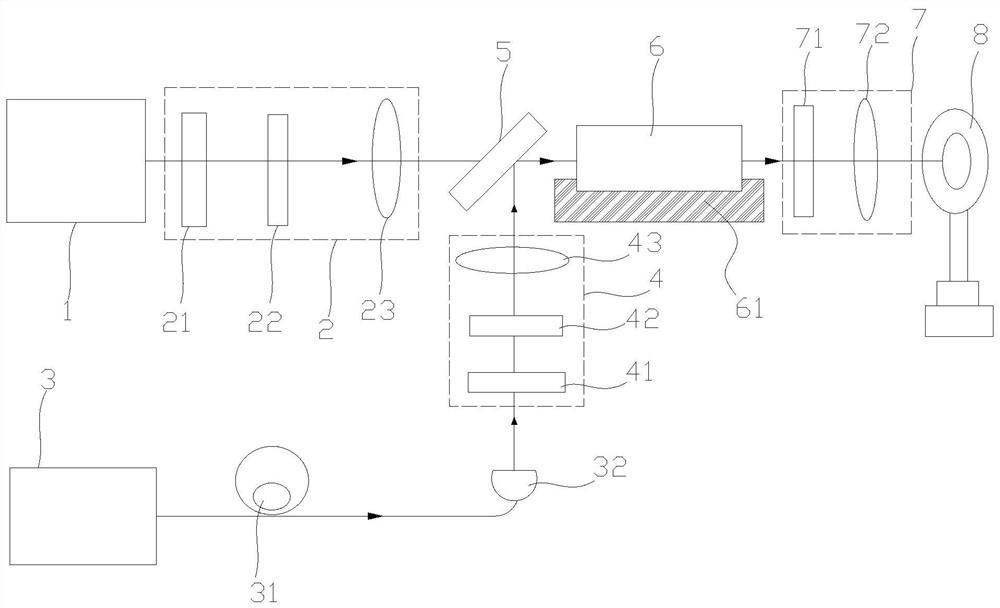

[0054] A white light laser source generating device, such as figure 1 As shown, the device includes the following components:

[0055] A first pump laser 1, configured to generate a first pump laser;

[0056] The second pump laser 3 is used to generate a second pump laser;

[0057] The wavelength of the first pump laser is smaller than the wavelength of the second pump laser;

[0058] The first polarization and focusing module 2 located between the first pump laser 1 and the laser beam combiner 5, the first polarization and focusing module 2 is used to transmit the first pump laser output from the first pump laser 1 to the laser beam combiner 5;

[0059] The second polarization and focusing module 4 located between the fiber coupling head 32 and the laser beam combiner 5, the second polarization and focusing module 4 is used to transmit the second pump laser output from the fiber coupling head 32 to the laser beam combiner 5 ;

[0060] The laser beam combiner 5 is used to...

Embodiment 2

[0069] On the basis of Example 1, a method for generating a white light laser light source, setting the temperature of the periodically polarized crystal 6 at 21° C. to 22° C. includes the following steps:

[0070] S1, the first pump laser 1 outputs a first pump laser with a wavelength of 760nm-800nm; the second pump laser 3 outputs a second pump laser with a wavelength of 1000nm-1100nm;

[0071] S2, the laser beam combiner 5 integrates the first pump laser and the second pump laser in step S1 so that all the pump lasers are emitted from the laser beam combiner 5 in the same optical path direction;

[0072] S3, the first pump laser and the second pump laser located in the same optical path direction in step S2 enter the periodically polarized crystal 6, and the periodically polarized crystal 6 generates the first pump laser with a wavelength of 380nm-400nm violet laser, the periodically polarized crystal 6 generates a green laser with a wavelength of 500nm to 550nm for the sec...

Embodiment 3

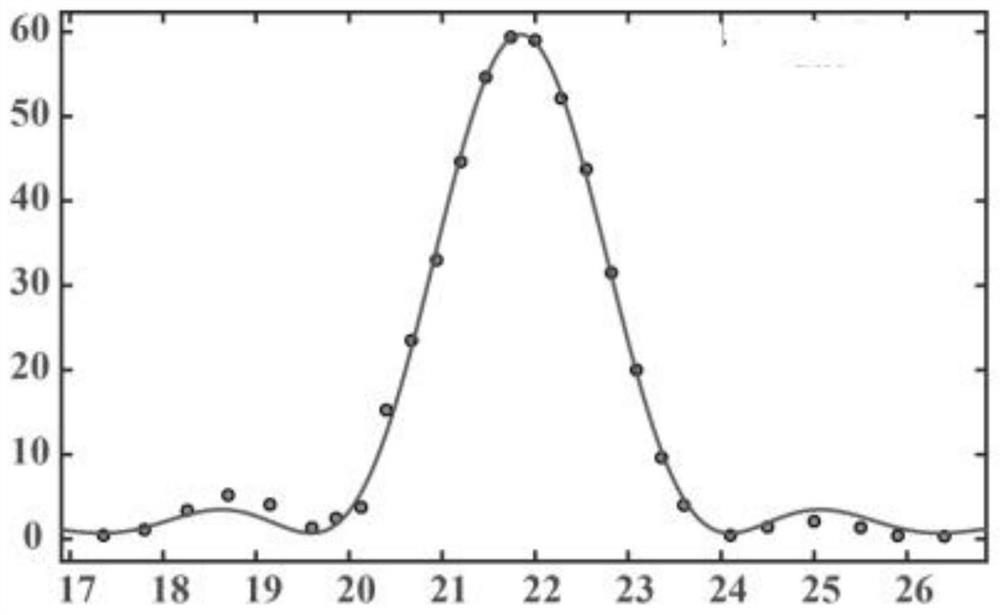

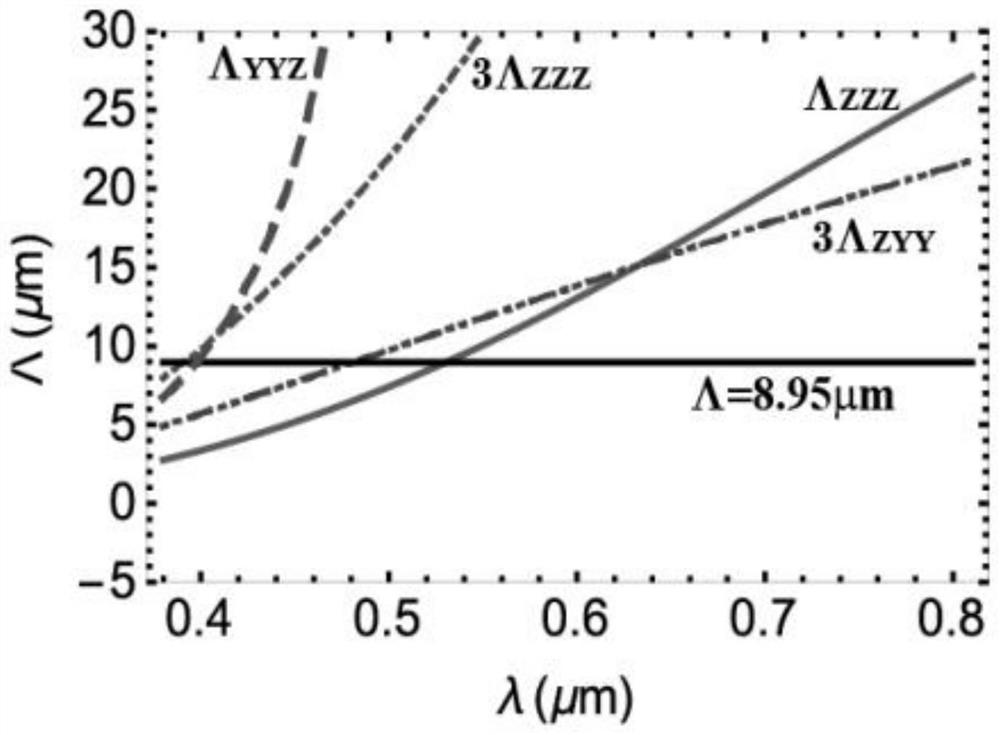

[0077] On the basis of Embodiment 2, the polarization period Λ of the periodically poled crystal 6 of the present embodiment is 8.95um, the wavelength of the first pump laser is 784nm, the wavelength of the second pump laser is 1063.8nm, and the violet laser The wavelength of the laser is 392nm, and the wavelength of the green laser is 531.9nm. Such as figure 2 As shown, the abscissa is the temperature of the periodically polarized crystal 6, and the ordinate is the conversion rate of the first pump laser with a wavelength of 784nm to generate a violet laser with a wavelength of 392nm by the periodically polarized crystal 6 and the periodic poled crystal 6 The conversion rate of the second pump laser with a wavelength of 1063.8nm to generate a green laser with a wavelength of 531.9nm, from figure 2 It can be known that at the same temperature, the conversion rates of the two are the same. In this embodiment, the temperature of the periodically poled crystal 6 is set at 21....

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com