Method for improving stability of water-soluble microcapsule fat powder

A technology of microcapsules and fat powder, which is applied in the molding or processing of animal feed, additional food elements, animal feed, etc., can solve the problems of shortened shelf life, flocculation, and poor bioavailability stability of feed products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

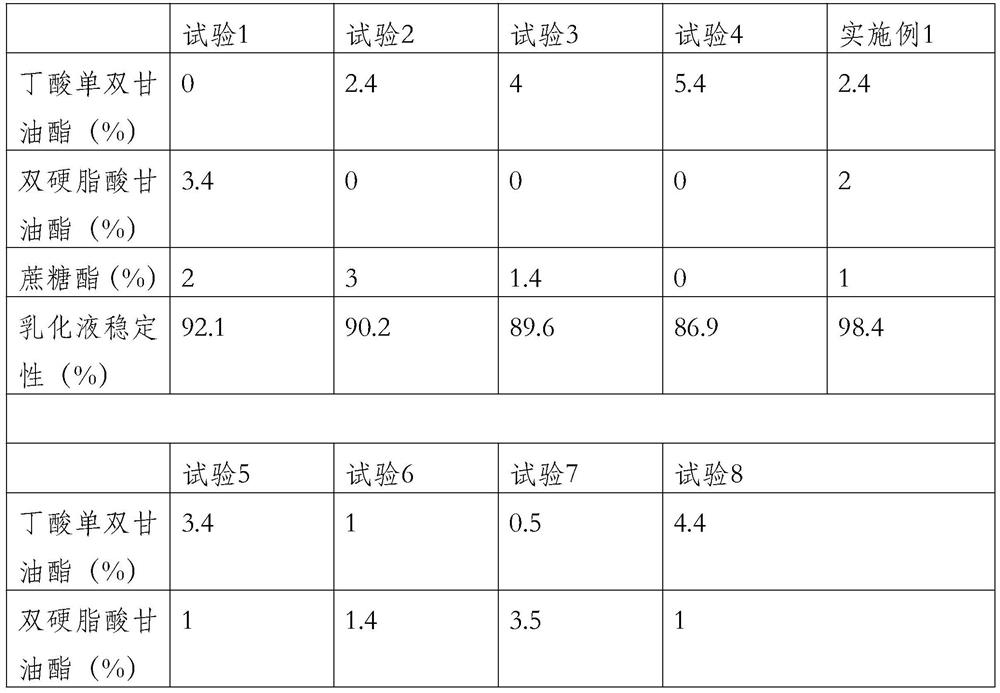

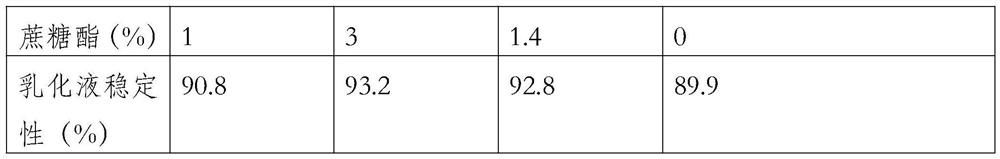

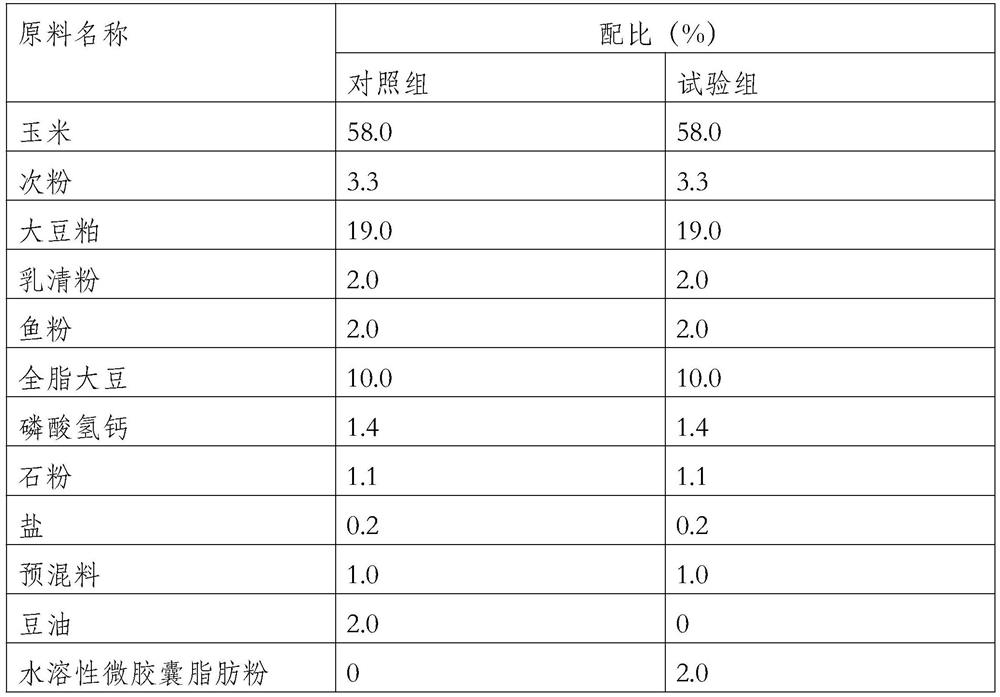

[0035] The present embodiment provides a kind of method that improves the stability of water-soluble microcapsule fat powder:

[0036] (1) Materials: disodium hydrogen phosphate, soybean protein isolate, maltodextrin, corn syrup, lactose, gum arabic, butyric acid mono-diglycerides, distearic acid glyceryl esters, sucrose esters and oil, based on the total mass of each raw material In terms of percentage, the content of the disodium hydrogen phosphate is 0.8%, the content of the soybean protein isolate is 0.8%, the content of the maltodextrin is 12%, the content of the corn syrup is 10%, and the content of the lactose 8%, the gum arabic content is 6%, the butyrate mono-diglyceride content is 2.4%, the described glyceryl distearate content is 2%, the sucrose ester content is 1%, the Oil content is 57%, and the formula of described oil is: take the total mass of oil as percentage, 56% soybean oil, 4% olive oil, 15% coconut oil, 1% milk fat, 12% corn oil and 12% % peanut oil.

...

Embodiment 2

[0044] The present embodiment provides a kind of method that improves the stability of water-soluble microcapsule fat powder:

[0045](1) Materials: disodium hydrogen phosphate, soybean protein isolate, maltodextrin, corn syrup, lactose, gum arabic, butyric acid mono-diglycerides, distearic acid glyceryl esters, sucrose esters and oil, based on the total mass of each raw material In terms of percentage, the content of the disodium hydrogen phosphate is 0.8%, the content of the soybean protein isolate is 0.8%, the content of the maltodextrin is 12%, the content of the corn syrup is 10%, and the content of the lactose 8%, the gum arabic content is 6%, the butyrate mono-diglyceride content is 2.4%, the described glyceryl distearate content is 2%, the sucrose ester content is 1%, the Oil content is 57%, and the formula of described oil is: take the total mass of oil as percentage, 56% soybean oil, 4% olive oil, 15% coconut oil, 1% milk fat, 12% corn oil and 12% % peanut oil.

[...

Embodiment 3

[0052] The present embodiment provides a kind of method that improves the stability of water-soluble microcapsule fat powder:

[0053] (1) Materials: disodium hydrogen phosphate, soybean protein isolate, maltodextrin, corn syrup, lactose, gum arabic, butyric acid mono-diglycerides, distearic acid glyceryl esters, sucrose esters and oil, based on the total mass of each raw material In terms of percentage, the content of the disodium hydrogen phosphate is 0.8%, the content of the soybean protein isolate is 0.8%, the content of the maltodextrin is 12%, the content of the corn syrup is 10%, and the content of the lactose 8%, the gum arabic content is 6%, the butyrate mono-diglyceride content is 2.4%, the described glyceryl distearate content is 2%, the sucrose ester content is 1%, the Oil content is 57%, and the formula of described oil is: take the total mass of oil as percentage, 56% soybean oil, 4% olive oil, 15% coconut oil, 1% milk fat, 12% corn oil and 12% % peanut oil.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com