Preparation method of an easy-to-assemble ceramic drug delivery atomizing core

A technology of atomizing core and ceramics, which is applied in the direction of therapeutic atomizers, etc., can solve the problems of difficult assembly of atomizing core, grain growth, easy oxidation, etc., achieve precise temperature range control, reduce sintering temperature, and avoid The effect of oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

[0033] To prepare an easy-to-assemble ceramic drug delivery atomizing core, it is prepared according to the following steps:

[0034] (1) The ceramic powder and the PbO sintering aid were weighed according to the mass ratio of 95:5, and put into a mixer for mixing. The mixing time was 2 hours, and the mixed powder was obtained after uniform mixing. Among them, the ceramic powder is made of 20wt.% Al 2 o 3 , 75wt.% SiC, 5wt.% SiO 2 Composition, powder particle size 15μm;

[0035] (2) Mix the mixed powder and wax-based binder at a volume ratio of 58:42, carry out banburying, banburying temperature is 170°C, banburying time is 60min, and use a feeder to crush and extrude to obtain ceramic feed. Wherein, the wax-based binder is composed of PW:PP:EVA:SA=60:17:15:8 (mass ratio).

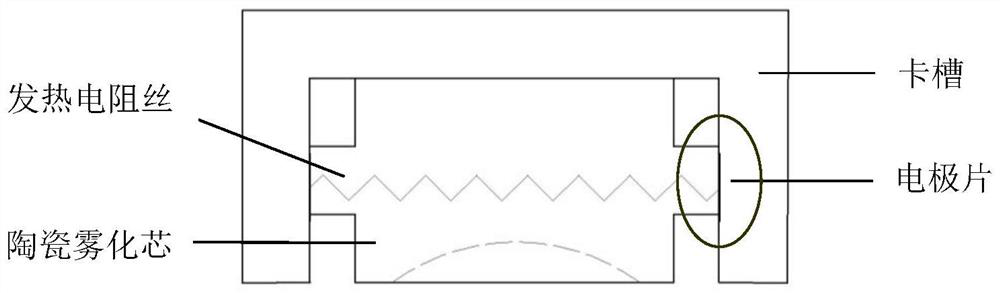

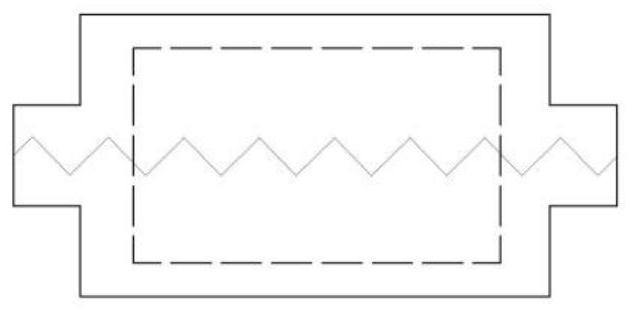

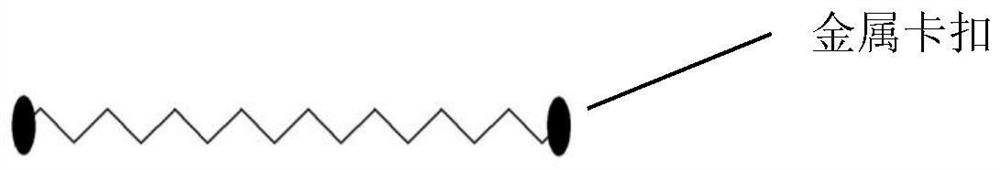

[0036] (3) Design and manufacture injection molds according to the shape of the atomizing core, so that each set of molds has 50 sets of cavities, and two concave points are provided on both sides of e...

Embodiment example 2

[0043] To prepare an easy-to-assemble ceramic drug delivery atomizing core, it is prepared according to the following steps:

[0044] (1) Combine ceramic powder with 1wt.%PbO3wt.%TiO 2 Weigh according to the proportion, and then put into a mixer for mixing, the mixing time is 4h, and the mixed powder is obtained after uniform mixing. Among them, the ceramic powder is composed of 70wt.% SiC, 30wt.% Al 2 o 3 Composition, powder particle size 8μm.

[0045] (2) Mix the mixed powder and the plastic-based binder at a volume ratio of 62:38, carry out banburying, the banburying temperature is 185°C, and the banburying time is 30 minutes, and crush and extrude with a feeder to obtain ceramic feed. Wherein, the plastic-based adhesive is composed of POM:PE:EVA:SA=83:10:5:2 (mass ratio).

[0046] (3) Design and manufacture injection molds according to the shape of the atomizing core, so that each set of molds has 40 sets of cavities, and two concave points are arranged on both sides o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com