On-line cyclone activity recovery method and device for catalyst in C5 petroleum resin production

An activity recovery, petroleum resin technology, applied in catalyst regeneration/reactivation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve problems such as catalyst deactivation, achieve slow deactivation process, short process, reduce consumption amount of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

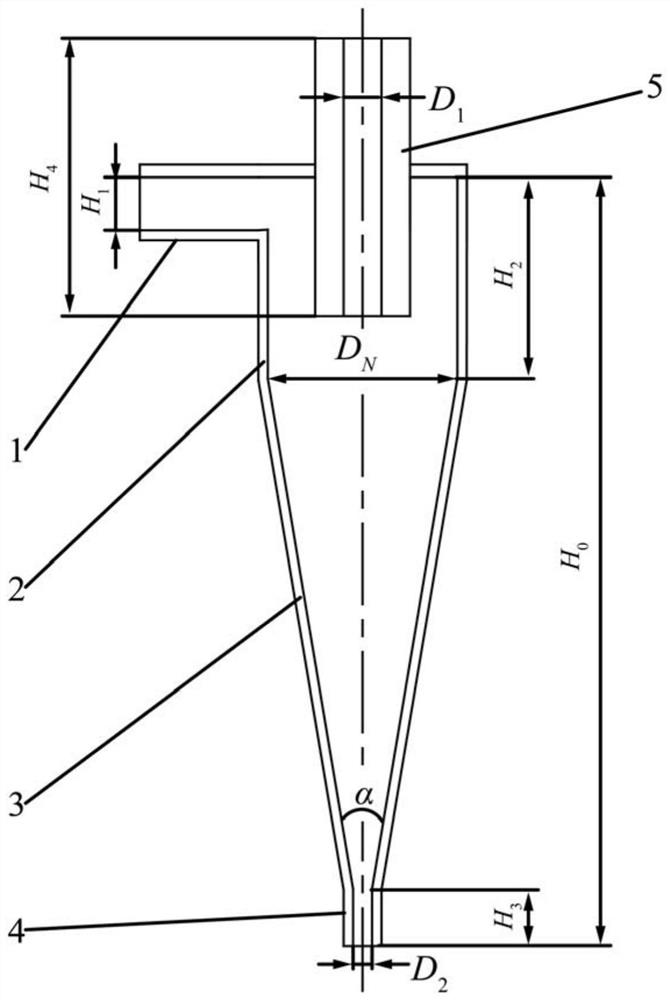

[0065] 1. Device name

[0066] 10L / h catalyst on-line cyclone activity recovery cyclone cold mold device.

[0067] 2. Technological process

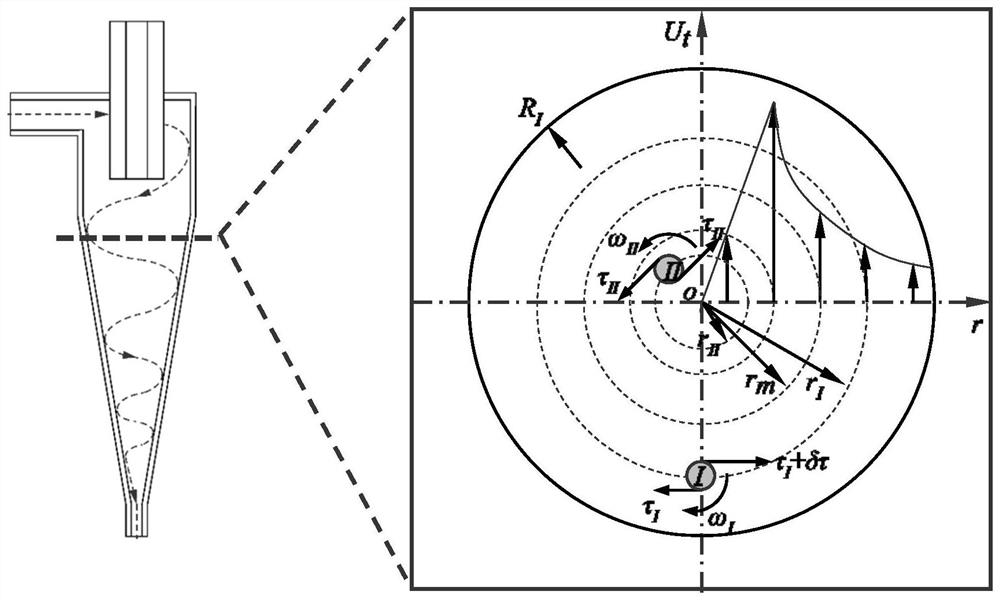

[0068] Such as Figure 4 shown. The tap water comes from the storage tank b. After being pressurized by the centrifugal pump a, the tap water enters the cyclone d from the tangential inlet of the cyclone d; the tap water carries the deactivated catalyst and enters the cyclone d from the tangential inlet; the liquid-solid two-phase While the mixture is separated by the cyclone, the deactivated catalyst undergoes orbital motion along the axis of the cyclone and the coupling motion of the particle axis rotates, and the activity of the catalyst is restored under the action of the coupled motion; Migrate downward to the side wall and flow out from the bottom outlet of cyclone d, and tap water flows out from the overflow port of cyclone d; after flowing out of the cyclone, the regenerated catalyst and tap water are re-mixed in the pipeline ...

Embodiment 2

[0078] 1. Device name

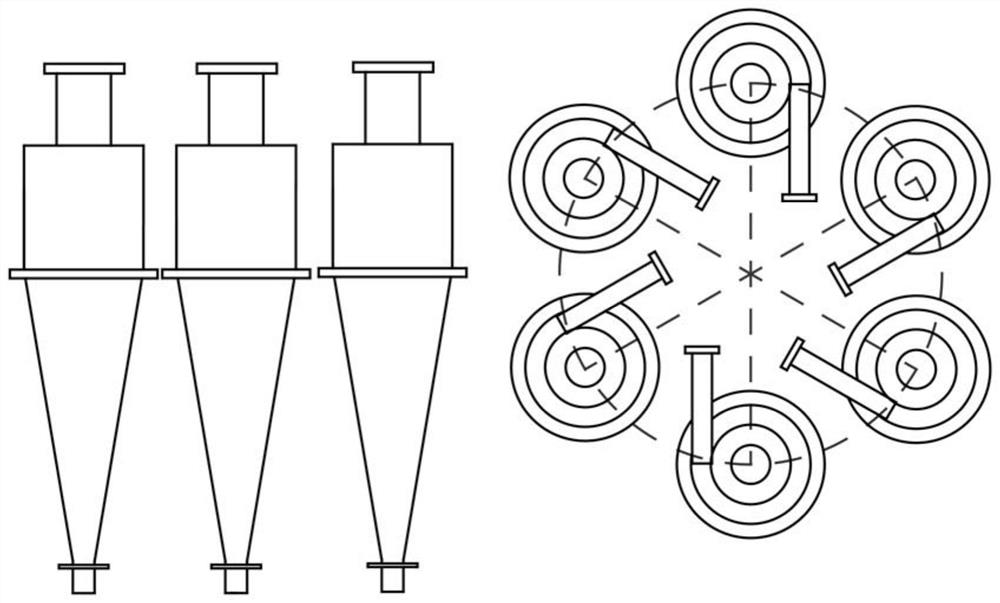

[0079] 450L / h C5 petroleum resin production process equipment.

[0080] 2. Technological process

[0081] Such as Figure 5 shown. The copolymerization liquid is added to the reactor A from the side of the reactor, and the catalyst is added to the reactor A from the top of the reactor A; the control range of the feed temperature of the copolymerization liquid and the catalyst is from room temperature to 55 ° C, and the mass ratio of the catalyst is controlled to be 0.992; Under the action of the catalyst, the cationic polymerization reaction of the liquid begins to occur; during this process, due to the violent reaction of the polymer, it is easy to produce detonation polymers to wrap the catalyst particles, and it is the catalyst that causes the catalyst to be unable to effectively participate in the reaction; the deactivated catalyst and the polymerization reactant form The two-phase mixture flows out from the bottom of the reactor A, the outlet pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com