Porous polythiophene nano-film loaded with nano zero-valent iron as well as preparation method and application of porous polythiophene nano-film

A nano-zero-valent iron and nano-film technology, which is applied in application, chemical instruments and methods, transportation and packaging, can solve the problems of poor monodispersity, easy agglomeration, and easy oxidation, so as to prevent agglomeration, expand specific surface area, and prevent The effect of oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The invention provides a preparation method of a porous polythiophene nano-film loaded with nano zero-valent iron, comprising the following steps:

[0034] (1) Preparation of porous polythiophene nanofilms by combining electrochemical polymerization and chemical oxidation;

[0035] (2) Porous polythiophene nanofilms loaded with nano-zero-valent iron were prepared by liquid phase reduction method.

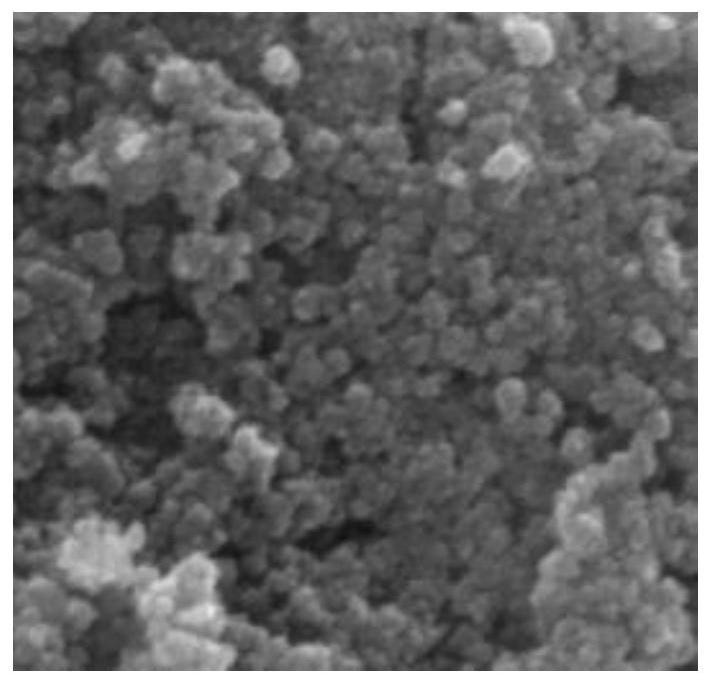

[0036] In the present invention, by loading nano-zero-valent iron on the porous polythiophene nano-film, on the one hand, it can greatly limit the loss of nano-zero-valent iron. The degree of "oxidation" maintains the high reactivity of nano-zero-valent iron, prevents it from being oxidized by non-target pollutants in the environment such as water, and prolongs its service life. At the same time, the loading of the porous polymer nano-film can effectively prevent its agglomeration, improve the dispersion, mechanical strength and adsorption effect of nano-zero-valent iron par...

Embodiment 1

[0049] The preparation process of the porous polythiophene nanofilm loaded with nano zero-valent iron is as follows:

[0050] (1) Preparation of porous polythiophene nanofilms by combining electrochemical polymerization and chemical oxidation

[0051] Polythiophene films were prepared by cyclic voltammetry electropolymerization on a CHI-660 electrochemical workstation, during which MnO was used 2 as an oxidizing agent. In the three-electrode system, a platinum sheet electrode was used as an auxiliary electrode, a saturated calomel electrode was used as a reference electrode, and the electrolyte was a mixed solution of thiophene and dilute sulfuric acid (concentration: 0.26 mol / L). The electrochemical polymerization conditions are: the polymerization voltage is 0.54V, the scanning rate is 6.5mV / s, and the scanning cycle is 25 cycles. The polymerization conditions are: add 2.5mL thiophene monomer to 400mL dilute sulfuric acid (concentration: 0.26mol / L), Then add 0.08g MnO 2 A...

Embodiment 2

[0056] The preparation process of the porous polythiophene nanofilm loaded with nano zero-valent iron is as follows:

[0057] (1) Preparation of porous polythiophene nanofilms by combining electrochemical polymerization and chemical oxidation

[0058] Polythiophene films were prepared by cyclic voltammetry electropolymerization on a CHI-660 electrochemical workstation, during which MnO was used 2 as an oxidizing agent. Under the three-electrode system, a platinum plate electrode is used as an auxiliary electrode, a saturated calomel electrode is used as a reference electrode, and the electrolyte is a mixed solution of thiophene and dilute sulfuric acid (concentration: 0.85 mol / L). Electrochemical polymerization conditions are: polymerization voltage is 0.5V, scanning rate is 12mV / s, and scanning cycle is 70 cycles. The polymerization conditions are: add 16mL thiophene monomer to 400mL dilute sulfuric acid (concentration: 0.85mol / L), and then add 1.4g MnO 2 After the polymer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com