Water-based playing card gloss oil with high gloss and high temperature resistance and preparation method thereof

A poker, high-gloss technology, applied in the field of water-based poker varnish and its preparation, can solve the problem of containing a large amount of solvents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

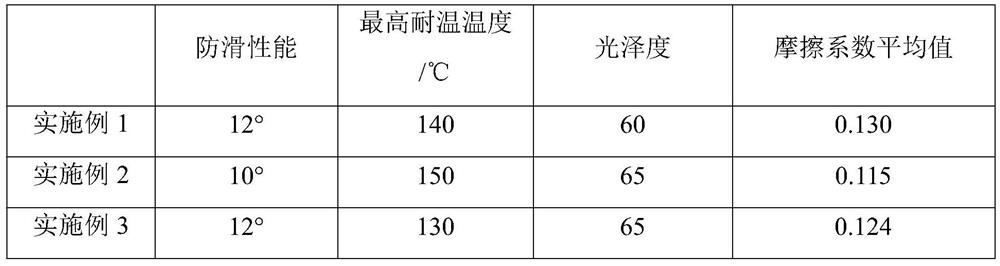

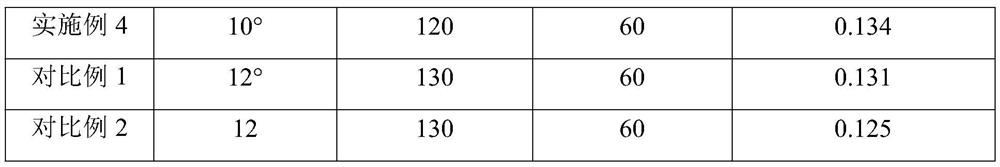

Examples

preparation example Construction

[0023] 1. The preparation method of water-based high-gloss resin liquid is:

[0024] (1) Take 100 parts of natural first-grade masson rosin resin from Jiangxi Jiajinlin Chemical Co., Ltd., put it into the reactor and heat it to 160°C. At this time, the rosin melts, start stirring, add 0.1 part of anthraquinone, and then heat up to 240°C. For decolorization treatment, the holding time is 3 hours. After the decolorization is completed, cool down to 170°C, add 20 parts of maleic anhydride to the kettle, raise the temperature to 220°C and keep it for 4 hours. At this time, the addition reaction is completed, and the temperature is maintained after the addition reaction is completed. At 220°C, add 10 parts of pentaerythritol into the kettle, control the reaction time within 2 hours, then cool down and purify to obtain solid particles, which are solid particles of water-based high-gloss resin;

[0025] (2) Take 40 parts of water-based high-gloss resin solid particles obtained in ste...

Embodiment 1

[0029] A water-based playing card varnish with high gloss and high temperature resistance, said water-based playing card varnish is made of the following raw materials in parts by mass: 10 parts of water-based styrene-acrylic non-film-forming emulsion (BASF J89 emulsion), water-based benzene Acrylic film-forming emulsion (BASF J77 emulsion) 10 parts, water-based high-gloss resin solution 50 parts, water-based modified resin solution 20 parts, silicone defoamer (DC65) 0.2 parts, polyethylene wax emulsion (Onkel MD2000, particle size 1μm) 3 parts, deionized water 5 parts, silicone hardening and slipping agent (DC51) 0.3 parts, organic solvent (absolute ethanol) 2 parts and organic solvent (propylene glycol butyl ether) 3 parts.

[0030] The preparation method of above-mentioned water-based playing card varnish comprises the following steps:

[0031] S1. Add the water-based styrene-acrylic non-film-forming emulsion into the reactor, keep the rotating speed at 800r / min, then pour ...

Embodiment 2

[0034]A water-based playing card varnish with high gloss and high temperature resistance, said water-based playing card varnish is made of the following raw materials in parts by mass: 20 parts of water-based styrene-acrylic non-film-forming emulsion (DSM A-1091) , 5 parts of water-based styrene-acrylic film-forming emulsion (BASF J77 emulsion), 50 parts of water-based high-gloss resin solution, 20 parts of water-based modified resin solution, 0.1 part of silicone defoamer (DC65), polyethylene wax emulsion (Gongyao 91240, Particle size is 1μm) 5 parts, deionized water 5 parts, silicone hardening slippery agent (DC51) 1 part and organic solvent (diethylene glycol butyl ether) 5 parts.

[0035] The preparation method of above-mentioned water-based playing card varnish is the same as embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com