A production system and method of an environmentally friendly wall decoration material

A wall decoration and production system technology, which is applied in the field of wall decoration materials, can solve problems such as insufficient mechanical strength and hardness, low appearance gloss, and easy damage of wall decoration materials, and achieve beautiful appearance, high hardness, and production low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

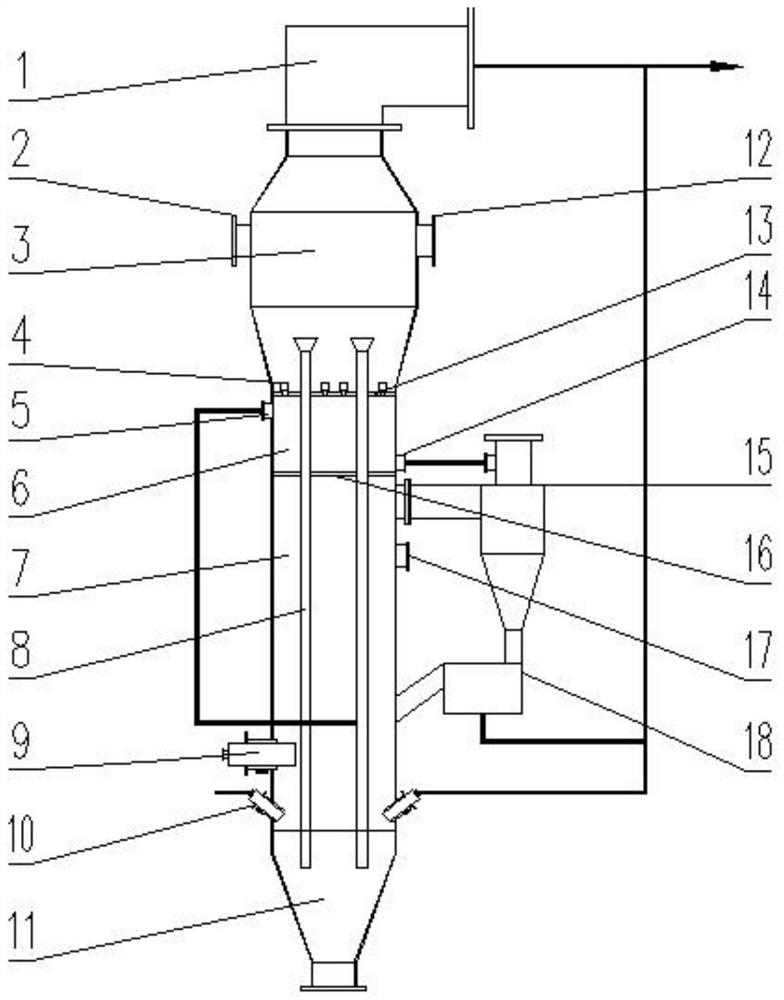

[0046] 1) Wood chips with an ash content of 0.5% and a particle size of 5 cm are added to the pyrolysis chamber 3 from the raw material inlet pipe 2, ceramic balls with a particle size of 1.5 mm are added to the pyrolysis chamber 3 from the bed material inlet pipe 12, and the flue gas is discharged from the flue gas chamber 6 Pass through the wind cap 4, the flue gas realizes the fluidization of the activated carbon raw material and the bed material, and the activated carbon raw material undergoes pyrolysis reaction in the pyrolysis chamber 3, and the pyrolysis reaction temperature is 700°C. During the pyrolysis process, the fluidization of the bed material The carbonized material that is broken into small particles falls into the activated settling tube 8, and the gas generated by the pyrolysis reaction and the flue gas are mixed to form a mixed gas. The mixed gas is divided into three paths, and the first path leaves the system and is used as a production heat source. , the s...

Embodiment 2

[0053] 1) Bamboo chips with an ash content of 0.6% and a particle diameter of 3 cm are added to the pyrolysis chamber 3 from the raw material inlet pipe 2, ceramic balls with a particle diameter of 2 mm are added to the pyrolysis chamber 3 from the bed material inlet pipe 12, and the flue gas is discharged from the flue gas chamber 6 Pass through the hood 4, the flue gas realizes the fluidization of the activated carbon raw material and the bed material, and the activated carbon raw material undergoes pyrolysis reaction in the pyrolysis chamber 3, and the pyrolysis reaction temperature is 680°C. During the pyrolysis process, the fluidization of the bed material The carbonized material that is broken into small particles falls into the activated settling tube 8, and the gas generated by the pyrolysis reaction and the flue gas are mixed to form a mixed gas. The mixed gas is divided into three paths, and the first path leaves the system and is used as a production heat source. , t...

Embodiment 3

[0060] 1) Coconut shell with ash content of 0.8% and particle diameter of 3 cm is added to pyrolysis chamber 3 from raw material inlet pipe 2, alumina balls with particle diameter of 3 mm are added to pyrolysis chamber 3 from bed material inlet pipe 12, and flue gas from flue gas The chamber 6 passes through the hood 4, and the flue gas realizes the fluidization of the activated carbon raw material and the bed material. The activated carbon raw material undergoes pyrolysis reaction in the pyrolysis chamber 3, and the pyrolysis reaction temperature is 650°C. During the pyrolysis process, the fluidization of the bed material The carbonized material is broken into small particles under the action, and the carbonized material falls into the activated settling tube 8, and the gas and flue gas generated by the pyrolysis reaction are mixed to form a mixed gas. The mixed gas is divided into three paths, and the first path leaves the system as a production heat source Use, the second wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com