Non-glass device for connecting laser gyroscope with exhaust station

A technology of laser gyroscope and connecting device, which is applied to lasers, laser parts, Sagnac effect gyroscopes, etc., can solve the problems of polluting the laser gyroscope and damaging the precision vacuum devices in the exhaust table.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

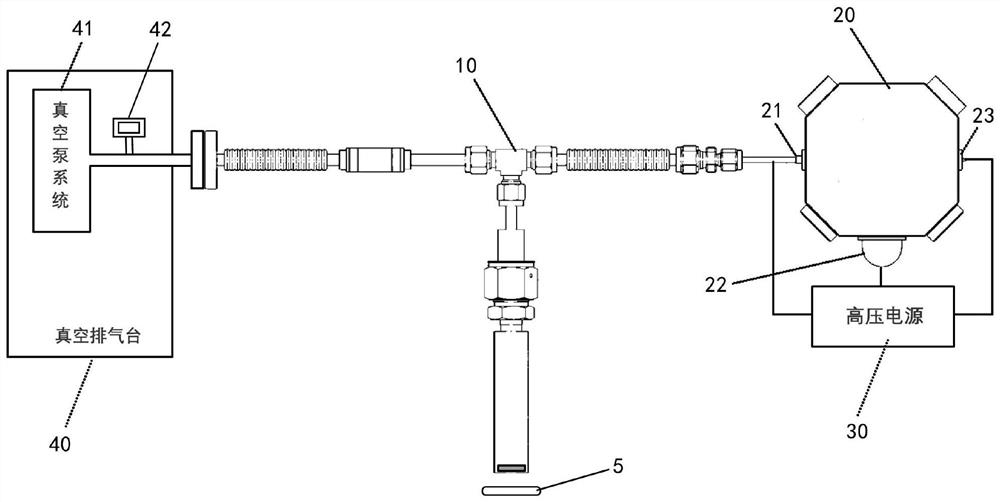

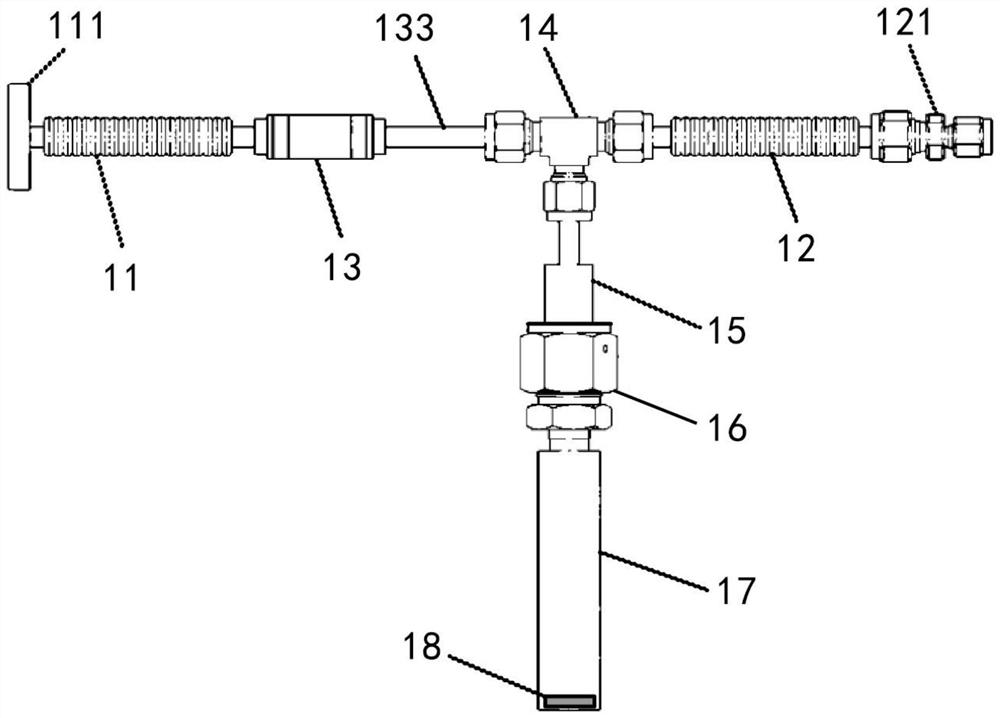

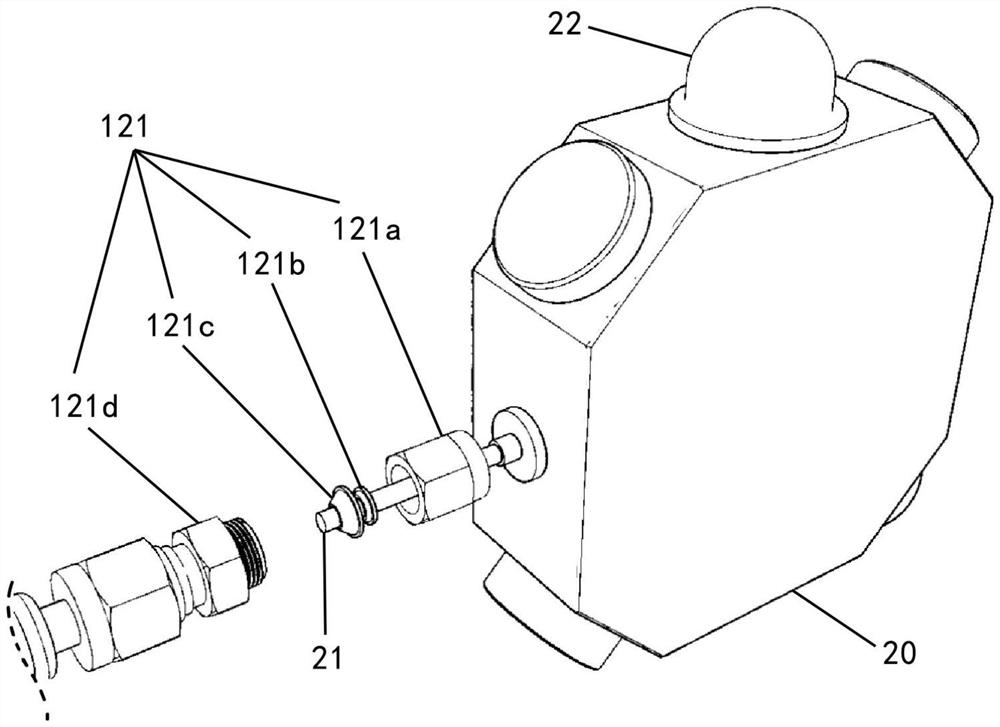

[0033]Such asFigure 1-6 As shown, a non-glass device for laser gyro 2 is connected to the discarisher, including a connecting device assembly 1, a laser gyro 2, a high voltage power source 3, a vacuum discharge station 4, and the activation coil 5. Wherein, the connecting device assembly 1 includes a bellows 11, a bellows two 12, a partition assembly 13, a three-way joint 14, a pair of tubing 15, a sealing joint 16, a storage tank 17, a suction agent 18; the bellows The flange interface 111 of the 11 11 is mounted to the flange of the vacuum air supply stage 4, thereby forming the flexible connection of the connecting device assembly 1 and the vacuum discharge station 4, and is used in the vacuum air supply stage 4 to generate a negative pressure. The vacuum pump system 41 is provided with a vacuum meter 42 on the line between the flange interface 111, and the measurement accuracy of the vacuum gauge 42 is 1 × 10-7The other end of the bellows 11 is connected to the three-way joint 1...

Embodiment 2

[0040]This example differs from the embodiment one in the first embodiment in that the connection device assembly 1 further includes a split ring 19, the split ring 19 is a cyclic body made of a magnetic alloy material, its annular inner diameter and storage can 17 The outer diameter showing an interference with the relationship.

[0041]Such asFigure 7 As shown, when activation is performed on the intake agent 18 using the activation coil 5, the shunt ring 19 is set to the outer wall of the bottom of the storage can 17, so that the bottom surface of the shunt ring 19 is flush with the storage tank 17. At this time, the activation coil 5 is activated according to the same parameters and method described in the first embodiment, and the thermal effect of high frequency alternating current is used, and a large amount of induction eddy current of the activation coil 5 is concentrated in the activation of the suction agent 18. The outer wall of the shunt ring 19 and the bottom of the stora...

Embodiment 3

[0047]The difference between the embodiment and the embodiment is that the connection device assembly 1 also includes a shunt ring 19, and the difference between the present embodiment and the second embodiment is that the outer wall of the shunt ring is provided with a snake shape. The rigid bump 19A of the line diameter distribution is arranged around the split ring 19 axis of the shunt ring 19 axis.

[0048]Such asFigure 7 As shown, the split ring 19 with the split edge 19a is sleened from the outer wall of the bottom of the storage tank 17, so that the bottom surface of the shunt ring 19 is flush with the storage tank 17, and the same as the same as described in the second embodiment. Parameters and methods are started to activate the coil 5.

[0049]Such asFigure 8 As shown, when the excitation coil generates a high-frequency electromagnetic field action shunt ring 19 to generate a high-frequency inductive vortex, since the high frequency current skin effect causes it to concentrate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com