Functional whole-grain mixed soybean milk and production method thereof

A production method and whole grain technology, applied in milk substitutes, dairy products, food science, etc., can solve problems such as product particle fineness index, high cost, complicated process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030]Method for producing a functional whole grain mixed bean milk, including:

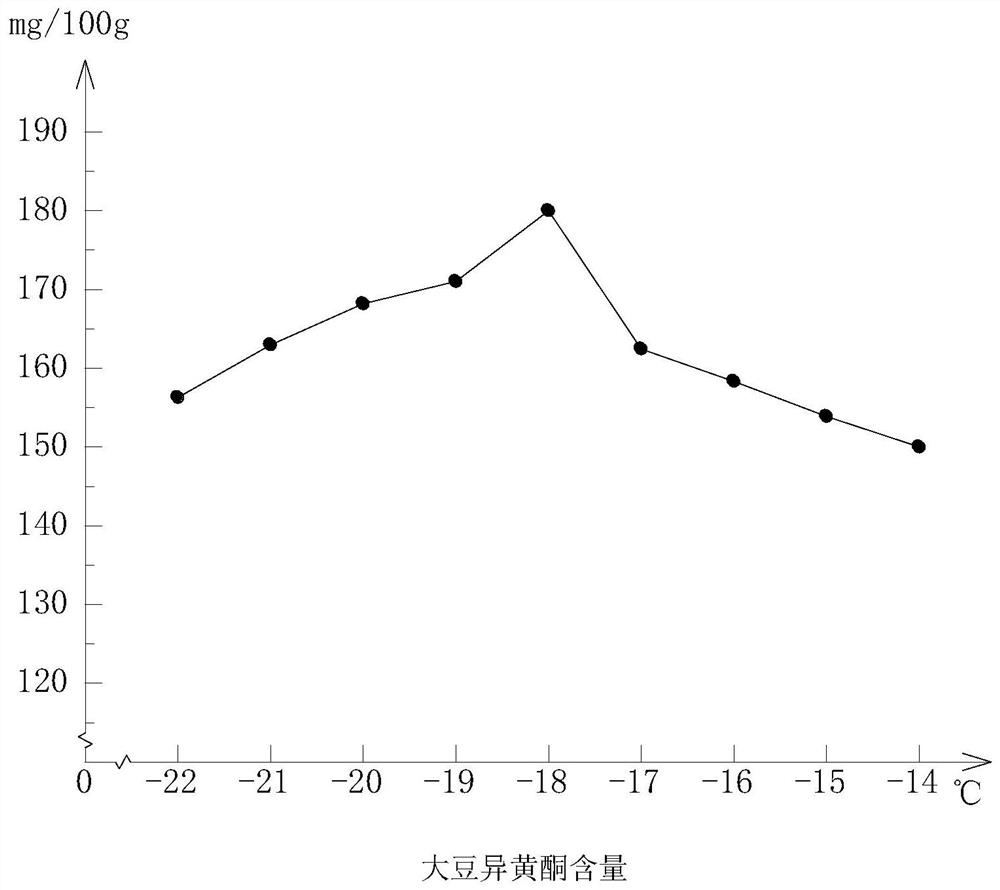

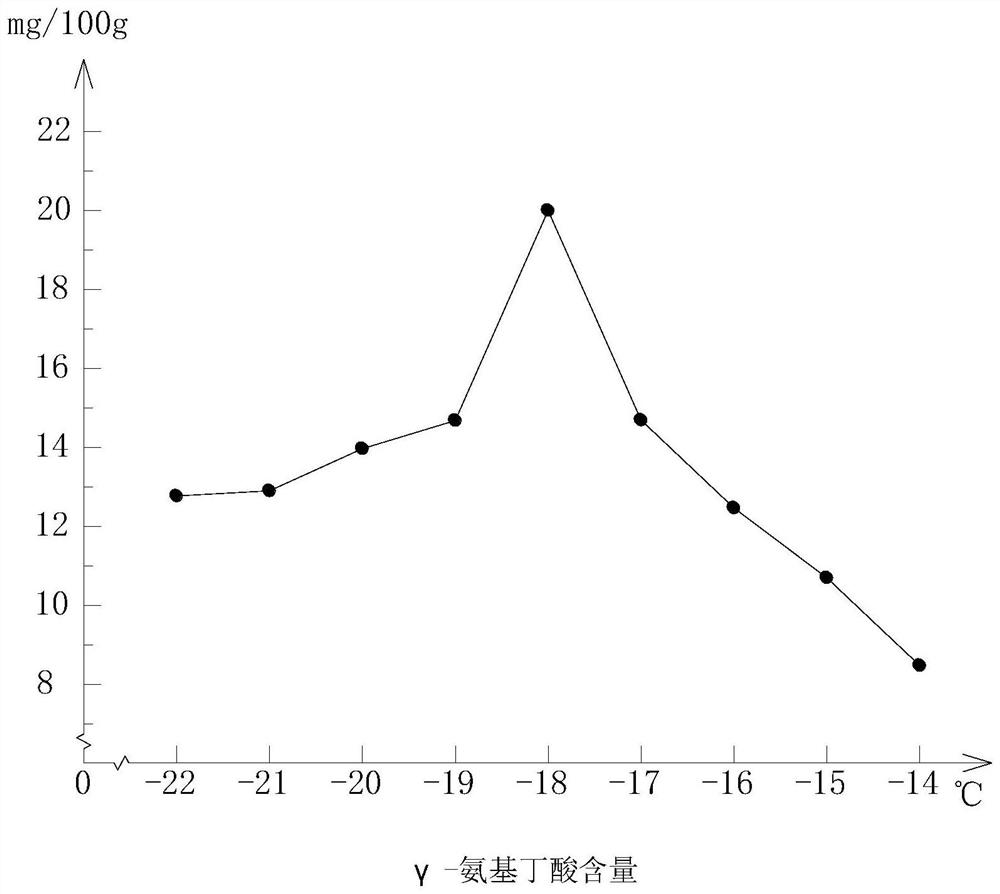

[0031](1) Soybean treatment: Choose the granules, no pest and disease, the reserved soybeans received, add 4 times the weight of water, soaked in water temperature 20 ° C, soak 12h, put the soaking good soy is placed in automatic bean sprouts In the machine, the temperature is 23 ° C, once every 3.5 h, protected from 48 h, and then freeze 10 h in an environment after the germinated soy is placed in the -18 ° C, resulting in germination soybeans;

[0032](2) Spirus brown rice treatment: After washing brown rice, put the nylon mesh bag, add 6 times weight of water soaked brown rice, soaked in water temperature 10 ° C, soak 12h, the germination control temperature is 15 ° C, the relative humidity is 90%, germination 2D, germination brown rice;

[0033](3) Cooking treatment: After mixing germination soybeans and germination brown rice, the weight ratio of 1: 0.08 is added to the weight of pure water, mix well, heat...

Embodiment 2

[0038]Method for producing a functional whole grain mixed bean milk, including:

[0039](1) Soybean treatment: Choose the granules, no pest and disease, the goods received, additional cleaning, add 5 times the weight of water, soak the water temperature 26 ° C, soak 11h, put the soaking good soy is placed in automatic bean sprouts In the machine, the temperature is 25 ° C, once every 4h, the sprout is 48h, and then the germinated soy is placed in an environment of -18 ° C for 12 h, resulting in germination soybeans;

[0040](2) Spirus brown rice treatment: After cleaning brown rice, placed in a nylon mesh bag, add 8 times weight water soaked brown rice, soaked in water temperature 13 ° C, soaked 11h, germination treatment, the germination control temperature is 16 ° C, relative humidity is 90%, germination 2D, germination brown rice;

[0041](3) Cooking treatment: After mixing germination soybeans and germination brown rice, add 9 times weight of pure water, mix evenly, mix well to 98 ° C, h...

Embodiment 3

[0046]Method for producing a functional whole grain mixed bean milk, including:

[0047](1) Soybean treatment: Choose the granules, no pests and the receiving soybeans received, additional cleaning, add 6 times the weight of water, soak the water temperature 32 ° C, soak 10h, put the soaking good soy is placed in automatic bean sprouts In the plane, the temperature is 27 ° C, once every 4.5 h, protected from 48 h, and then frozen in an environment after the germinated soy is placed in an environment of -18 ° C for 16 h, resulting in germination soybeans;

[0048](2) Spirus brown rice treatment: After washing brown rice, put into the nylon net bag, add 10 times weight of water soaked brown rice, soaked in water temperature 16 ° C, soaked for 10 h, the germination control temperature is 18 ° C, the relative humidity is 90%, germination 2D, germination brown rice;

[0049](3) Cooking treatment: After mixing the germination soybean and germination brown rice 1: 0.12, add 10 times weight of pure ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com