Preparation method of Fe3O4-biochar composite nanomaterial and method for degrading organic pollutants in water body

A technology of composite nanomaterials and organic pollutants, applied in water pollutants, water/sludge/sewage treatment, metal/metal oxide/metal hydroxide catalysts, etc., can solve the difficulty of microorganism cultivation and screening, and limit technology Problems such as application and treatment efficiency, insufficient adsorption capacity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] a Fe 3 O 4 -The preparation method of biochar composite nanomaterial, comprising steps as follows:

[0043] 1) After drying in an oven at 80°C, pulverize the fallen leaves of Arborvitae into powder, place the powder in a tubular furnace at 600°C, decarbonize with nitrogen for 2 hours, and soak the obtained black powder in a 1mol / L hydrochloric acid solution. Inorganic components were removed for 24 hours, washed with water until neutral, and dried to obtain biochar;

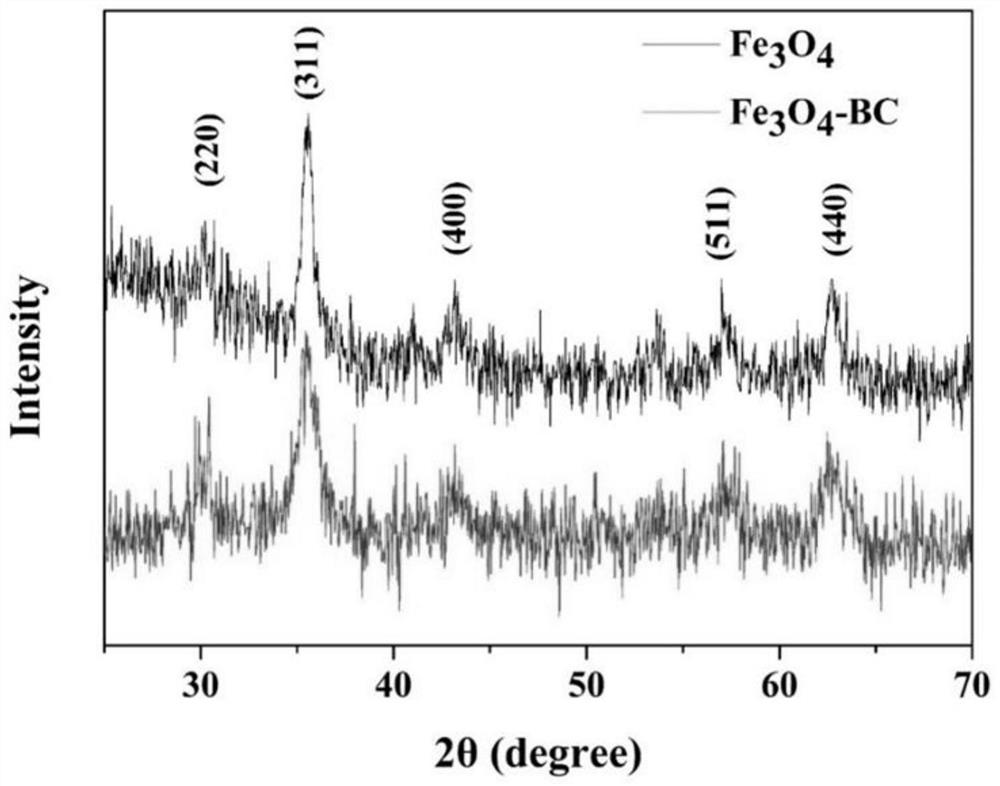

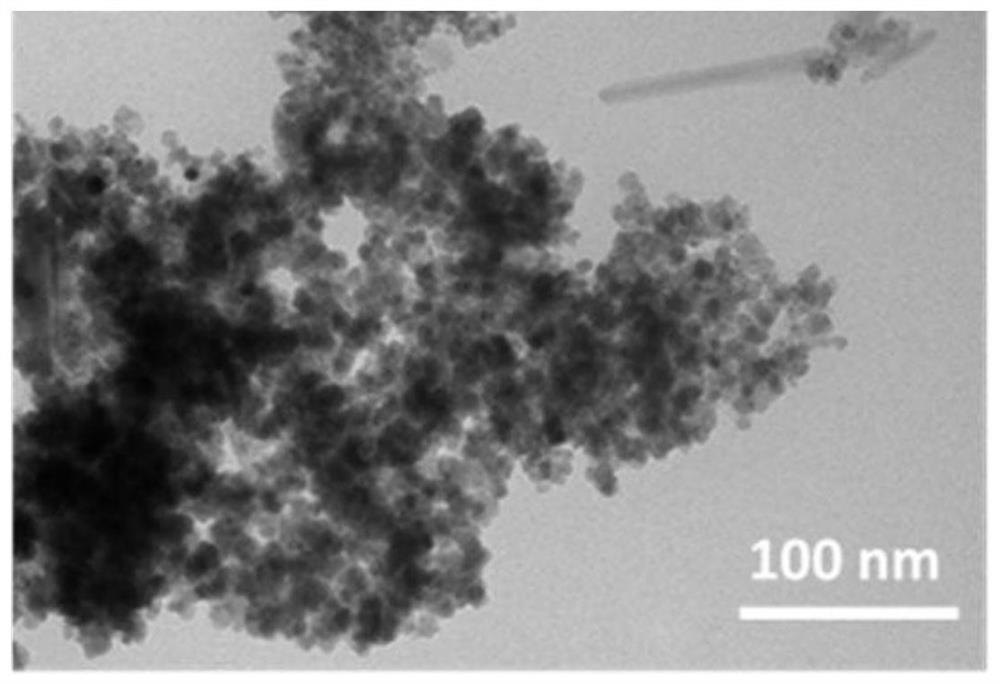

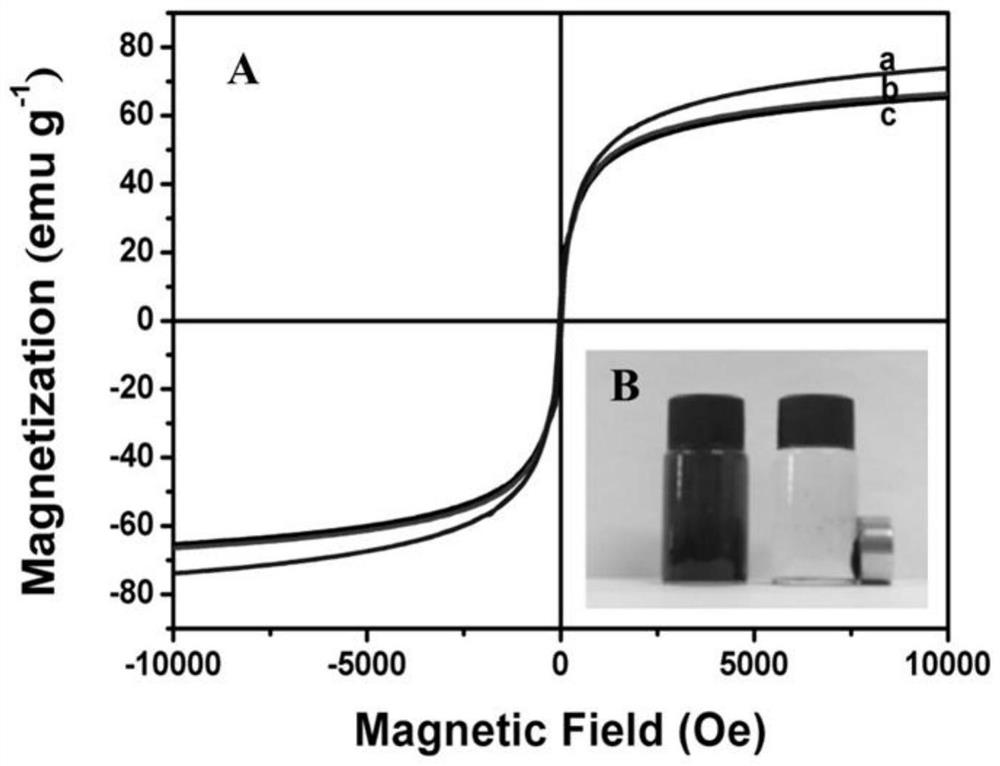

[0044]2) One-step co-precipitation method to synthesize Fe 3 O 4 - Biochar composite nanomaterials: 0.001mol FeSO 4 ·7H 2 0 and 0.02mol FeCl 3 ·6H 2 0 Add 30ml of 0.01mol / L hydrochloric acid solution, add 2g of biochar after dissolving, stir mechanically, then transfer the mixture to a 500ml three-necked flask, and introduce nitrogen for continuous stirring for 30 minutes. 80ml of 3mol / L NaOH solution was added dropwise, and after continuous stirring for 3h reaction, alternately washed with ultrapu...

Embodiment 2

[0047] A Fe-based 3 O 4 A method for degrading organic pollutants in water (taking bisphenol A as an example) by the peroxymonosulfate system of biochar composite nanomaterials, the steps are as follows:

[0048] will Fe 3 O 4 - Biochar composite nanomaterials are added to wastewater containing bisphenol A, Fe 3 O 4 - The dosage of biochar composite nanomaterials is 1.5g / L, and then permonosulfate is added to make the concentration reach 3mM, pH=3.0, and the system is placed in a constant temperature shaker at 30°C, and the reaction time is 120min. Keep other conditions unchanged, only replace Fe 3 O 4 - Biochar composite nanomaterials are biochar and Fe 3 O 4 , the removal results see Figure 4 .

[0049] For comparison, the embodiment compares at the same time without adding permonosulfate (PMS), only adding Fe 3 O 4 , biochar, Fe 3 O 4 - Biochar, adding Fe at the same time 3 O 4 In the four cases of biochar and biochar, the dosage was 1.5g / L, the pH was adju...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com