Symphytum officinale polysaccharide based on response surface method optimized enzyme-assisted extraction and preparation method and application thereof

A response surface methodology, a technology of polymerizing grass, applied in the field of polymerized grass polysaccharide and its preparation, can solve the problems that the research on the effect of polymerized grass polysaccharide enzyme on chicken cecal flora has not been carried out, and the research of polymerized grass polysaccharide is not in-depth enough.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045]First, the present invention provides a method for preparing a polymerized polysaccharide with a response surface method optimizing an enzyme, including the following steps:

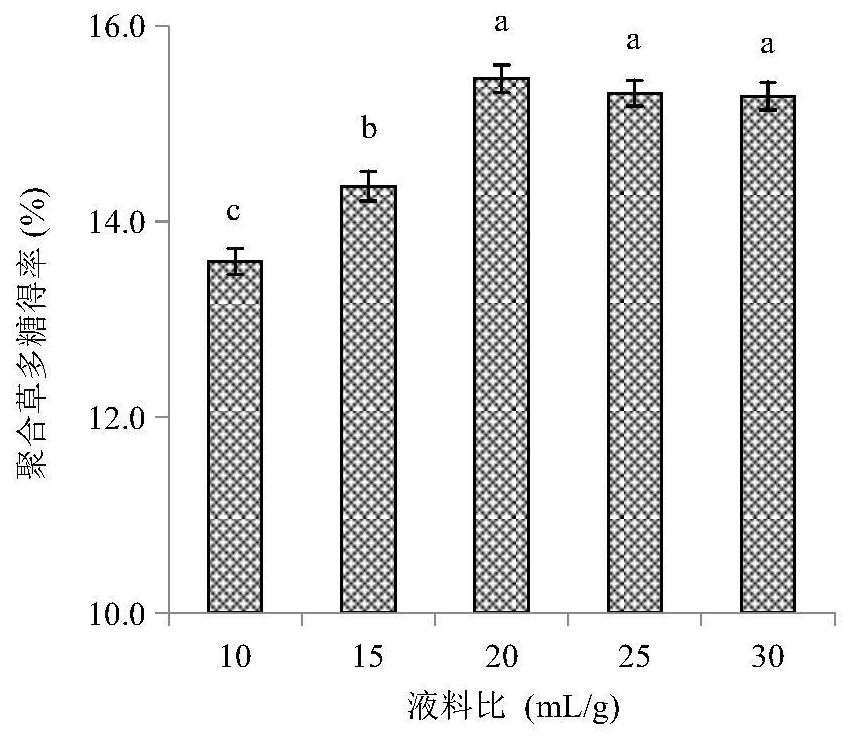

[0046]Step 1: Extract

[0047]The polymer wash was washed and pulverized, and the drying temperature of the polymerization was preferably from 50 ° C, and the sieve size was preferably 1 mM to obtain polymerization grass powder; the resulting polymerized flour powder was soaked. At the same time, the complex enzyme was added and the pH was adjusted to obtain an extract, and the polymerization powder soaking temperature is preferably 50 ° C, and the polymerization powder soaking time is preferably 60 min, and the amount ratio of the water and polymerization grass powder is preferably 20mL / g, the composite enzyme as a hydraulic condition having a hydrated amount of 1%, the specific component and mass ratio of the composite enzyme: pectinase: papain protease = 1: 1: 1, the adjustment pH value Preferably, the ex...

Embodiment 1

[0065]The polyheetic washed, dried under 50 ° C, and pulverized it was dried and passed by 1 mm sieve to obtain a polymerization powder; add the obtained polymeral powder to water to soak for 60 min, and 1% compound enzyme The pH is adjusted to obtain the extract, the amount of water and polymerization powder is 20 mL / g, the composite enzyme specific component and mass ratio of cellulase: pectinase: papain protease = 1: 1 : 1; After soaking, the extract is filtered, the filtrate is concentrated to concentrate;

[0066]Step 2: Alcoholization

[0067]The concentration of 75% in the concentration of 75% was slowly added to the concentrate, and placed at 4 ° C for 12 h, then centrifuged, centrifugal speed was 3000 r / min, centrifugal time was 15 min, and the supernatant was discarded after centrifugation. Polymerized polysaccharide precipitation;

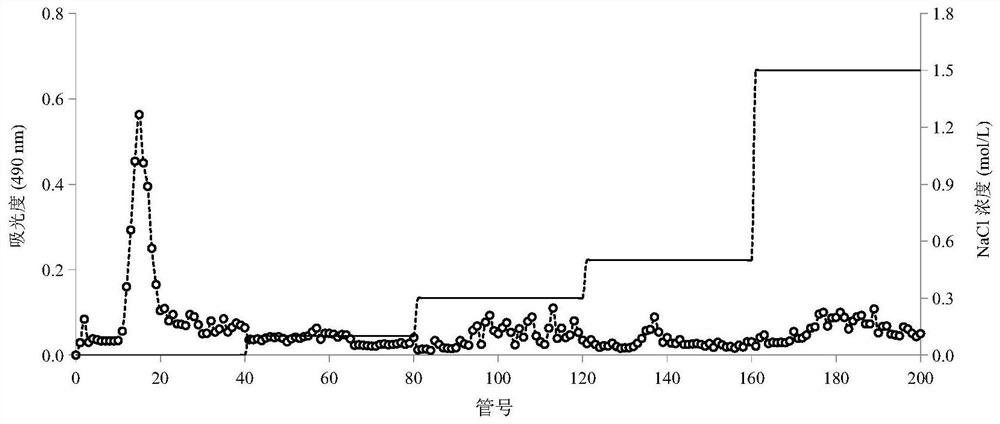

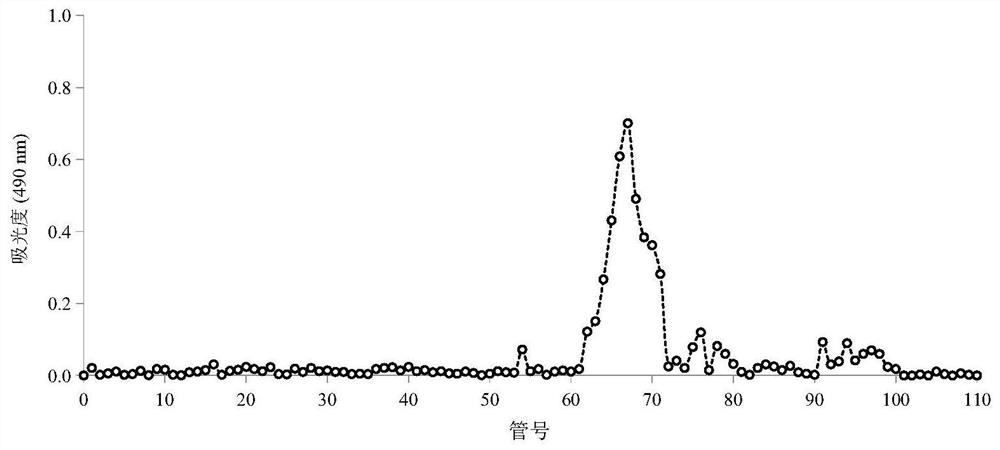

[0068]Step 3: Go to the protein

[0069]The resulting polymerized grass polysaccharide precipitate was dissolved in water, and the polymerized polysa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com