Plant fiber with high degradation speed and preparation method thereof

A plant fiber and degradation rate technology, applied in the fiber field, can solve the problems of plant fiber toughness and elastic properties that need to be improved, soil microorganisms to nourish the land, and the degradation rate to be improved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

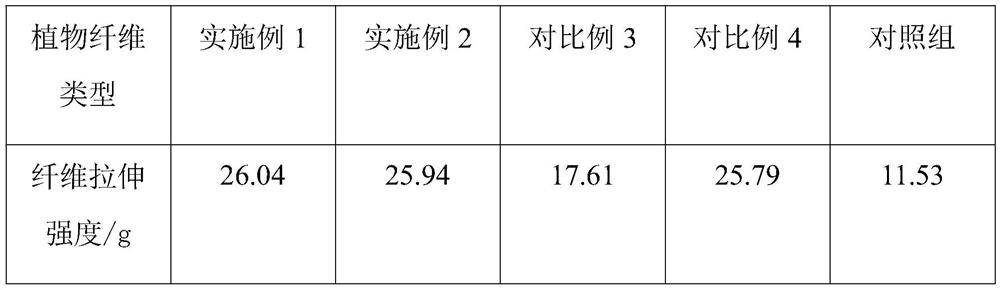

Examples

preparation example Construction

[0033] (2) Preparation of pre-modified plant fibers: reacting the plant fibers extracted in step (1) with ethylenediamine;

[0034] (3) Preparation of modified plant fiber: reacting the pre-modified plant fiber gained in step (2) with brominated n-butane;

[0035] (4) Treating the modified fiber obtained in step (3) with a softener and an antifungal agent to obtain a plant fiber with a fast degradation rate.

[0036] Preferably, the plant fiber extraction step in the step (1) is as follows: select plants with excellent varieties and place them in a pulverizer to be crushed to 1-5cm fragments, and then roll the plant fragments, and the rolled plants The fragments are soaked in 90% to 95% acetone solution for 8 to 10 days, filtered to obtain a filter residue, and then the filter residue is cooked to separate the stem tissue from the plant fiber precursor, and after filtering again, the plant fiber precursor is Centrifuge to remove residual oil cells and stem tissue, rinse with ...

Embodiment 1

[0039] Embodiment 1: fast plant fiber one of degrading speed:

[0040] A kind of plant fiber with fast degradation rate, the fiber component is by weight:

[0041] 35 parts of modified plant fiber, 55 parts of crop plants, 5 parts of softener, 5 parts of antifungal agent, 5 parts of antioxidant, some deionized water.

[0042] The preparation method of this plant fiber is as follows:

[0043] (1) Extraction of plant fiber;

[0044] (2) Preparation of pre-modified plant fibers: reacting the plant fibers extracted in step (1) with ethylenediamine;

[0045] (3) Preparation of modified plant fiber: reacting the pre-modified plant fiber gained in step (2) with brominated n-butane;

[0046] (4) Treating the modified fiber obtained in step (3) with a softener and an antifungal agent to obtain a plant fiber with a fast degradation rate.

[0047] Preferably, the plant fiber extraction step in the step (1) is as follows: select plants with excellent varieties and place them in a pulv...

Embodiment 2

[0050] Embodiment 2: fast plant fiber two of degrading speed:

[0051] A plant fiber with fast degradation rate, the components of the plant fiber are in parts by weight:

[0052] 50 parts of modified plant fiber, 100 parts of crop plants, 10 parts of softener, 10 parts of antifungal agent, 10 parts of antioxidant, some deionized water.

[0053] The preparation method of this plant fiber is as follows:

[0054] (1) Extraction of plant fiber;

[0055] (2) Preparation of pre-modified plant fibers: reacting the plant fibers extracted in step (1) with ethylenediamine;

[0056] (3) Preparation of modified plant fiber: reacting the pre-modified plant fiber gained in step (2) with brominated n-butane;

[0057] (4) Treating the modified fiber obtained in step (3) with a softener and an antifungal agent to obtain a plant fiber with a fast degradation rate.

[0058] Preferably, the plant fiber extraction step in the step (1) is as follows: select plants with good varieties and place...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com