Low-noise high-shielding fA-level current signal cable for radiation environment and manufacturing process

A technology of radiation environment and current signal, applied in communication cables, insulated cables, cable conductor structures, etc., can solve the problems of fast loss on the transmission path, not meeting strong radiation conditions, and low noise fA-level cables with high noise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

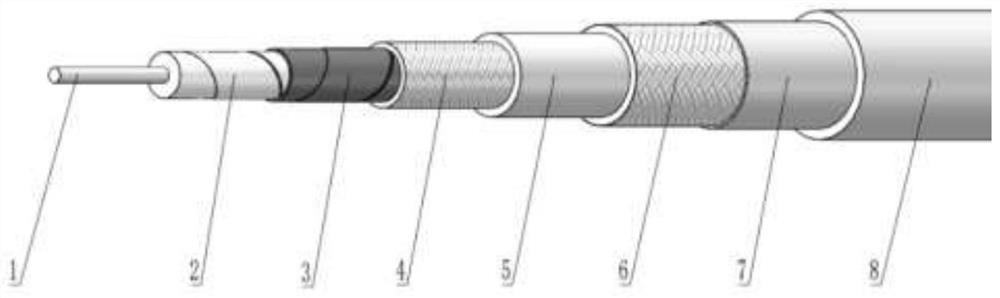

[0048] like figure 1 As shown, the low-noise and high-shield fA-level current signal cables for the radiation environment include:

[0049] an inner conductor 1 arranged at the center of the cable;

[0050] The wrapping insulating layer 2 , the wrapping semiconducting layer 3 , the outer conductor 4 , the inner sheath 5 , the outer shielding layer 6 , the wave-absorbing functional layer 7 and the outer sheath 8 are sequentially covered on the outer layer of the inner conductor 1 .

[0051] Preferably, the inner conductor 1 is composed of 19 silver-plated copper wires twisted around the central reinforcement filling fiber, wherein the diameter of a single silver-plated copper wire can be 0.10mm, 0.12mm or 0.16mm.

[0052] Preferably, the wrapping insulating layer 2 is composed of a cross-linked polytetrafluoroethylene film, and the insulating layer of the cross-linked polytetrafluoroethylene film has high strength, good aging resistance, high temperature resistance and high ra...

Embodiment 2

[0064] like figure 1 As shown, the low-noise and high-shield fA-level current signal cables for the radiation environment include:

[0065] an inner conductor 1 arranged at the center of the cable;

[0066] The wrapping insulating layer 2 , the wrapping semiconducting layer 3 , the outer conductor 4 , the inner sheath 5 , the outer shielding layer 6 , the wave-absorbing functional layer 7 and the outer sheath 8 are sequentially covered on the outer layer of the inner conductor 1 .

[0067] Preferably, the inner conductor 1 is composed of 26 silver-plated copper wires twisted around the central reinforcement filling fiber, wherein the diameter of a single silver-plated copper wire can be 0.10 mm or 0.12 mm.

[0068] Preferably, the wrapping insulating layer 2 is composed of a cross-linked polytetrafluoroethylene film, and the insulating layer of the cross-linked polytetrafluoroethylene film has high strength, good aging resistance, high temperature resistance and high radiatio...

Embodiment 3

[0079] like figure 1 As shown, the low-noise and high-shield fA-level current signal cables for the radiation environment include:

[0080] an inner conductor 1 arranged at the center of the cable;

[0081] The wrapping insulating layer 2 , the wrapping semiconducting layer 3 , the outer conductor 4 , the inner sheath 5 , the outer shielding layer 6 , the wave-absorbing functional layer 7 and the outer sheath 8 are sequentially covered on the outer layer of the inner conductor 1 .

[0082] Preferably, the inner conductor 1 is composed of 26 silver-plated copper wires twisted around the central reinforcing filling fiber, wherein the diameter of a single silver-plated copper wire can be 0.12mm or 0.16mm.

[0083] Preferably, the wrapping insulating layer 2 is composed of a cross-linked polytetrafluoroethylene film, and the insulating layer of the cross-linked polytetrafluoroethylene film has high strength, good aging resistance, high temperature resistance and high radiation re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com