Wire sheath and preparation process thereof

A technology of wire sheath and raw materials, applied in the direction of circuits, electrical components, plastic/resin/wax insulators, etc., can solve the problem of low tensile strength of wire sheath, achieve the effect of improving heat resistance, increasing strength, and reducing pollutants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

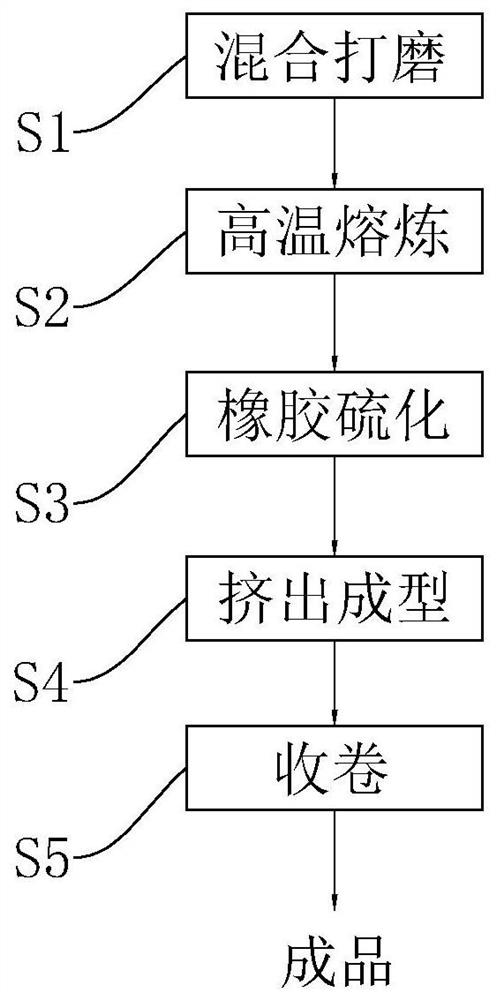

[0042] refer to figure 1 , this embodiment discloses a preparation process for an electric wire sheath, comprising the following steps:

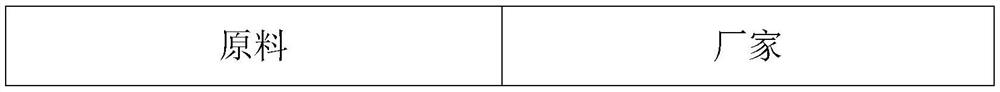

[0043] S1: mixed sanding. The raw materials of the electric wire sheath were added into the pulverizer in no order according to the weight part and pulverized to 200 mesh. Then all the crushed materials are transported to the mixer for stirring, and the stirring speed is 900r / min, and the stirring is continued for 25min. The raw materials of the wire sheath are 65 parts by weight of polyvinyl chloride resin, 130 parts of calcium carbonate, 6 parts of quartz, 12 parts of carbon black, 33 parts of chlorinated paraffin and 8 parts of dioctyl phthalate.

[0044] S2: high temperature melting. Transport the material after S1 treatment to a high-temperature calciner, and heat the material in the high-temperature calciner to 700°C, and keep stirring at this temperature for 15 minutes, and then keep it warm for 50 minutes.

[0045] S3: Rubber vul...

Embodiment 2

[0050] The difference from Example 1 is that the raw materials of the electric wire sheath are different. The raw materials of the dot line skin are 65 parts by weight of polyvinyl chloride resin, 130 parts of calcium carbonate, 6 parts of quartz, 12 parts of carbon black, 33 parts of chlorinated paraffin, 8 parts of dioctyl phthalate and 50 parts of chlorinated rubber share.

Embodiment 3

[0052] The difference from Example 1 is that the raw materials of the electric wire sheath are different. The raw materials of the dot line skin are 65 parts by weight of polyvinyl chloride resin, 130 parts of calcium carbonate, 6 parts of quartz, 12 parts of carbon black, 33 parts of chlorinated paraffin, 8 parts of dioctyl phthalate, and 50 parts of chlorinated rubber. parts and 34 parts of nylon.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com