Magnetic field auxiliary cathode arc striking device and film coating method

An arc striking device and a magnetic field assisted technology are applied in the field of magnetic field assisted cathode arc striking device and coating, which can solve the problems of reduced plasma density, reduced film deposition rate, affected production efficiency, etc., so as to reduce the generation of large particles and reduce large The formation of particles, the effect of improving the cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further explained in detail below in conjunction with the accompanying drawings and specific embodiments, but it should be understood that the protection scope of the present invention is not limited by the specific embodiments.

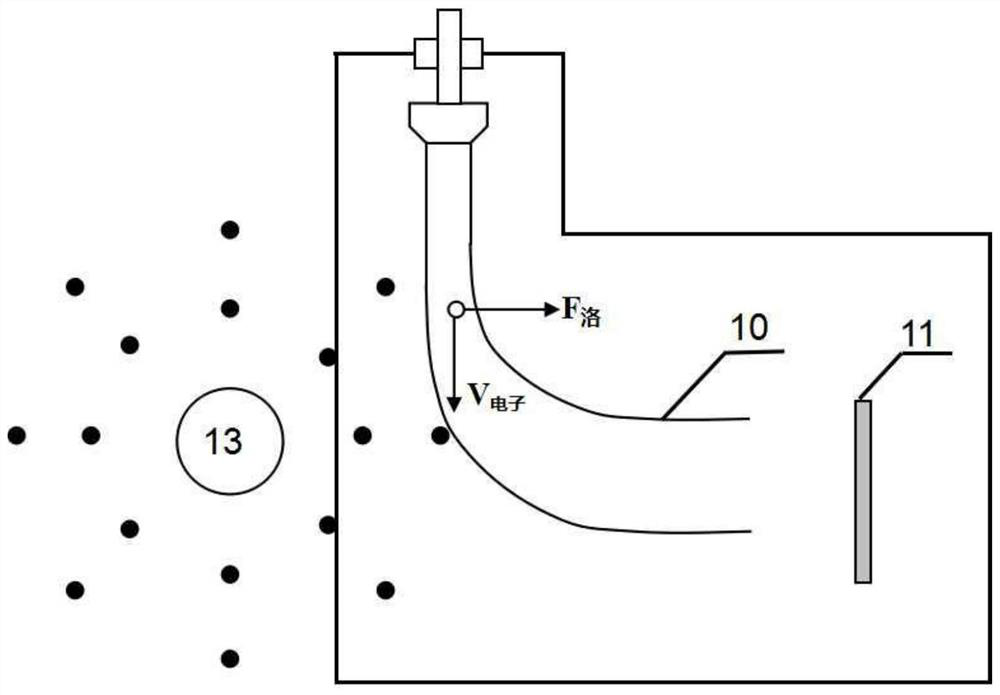

[0046] Such as Figure 1-4 As shown, the present invention proposes a magnetic field-assisted cathode arc striking device capable of producing high-quality coatings without large particles, which includes an arc striking system, a target, a magnetic deflection filter system, and a vacuum chamber (vacuum cavity).

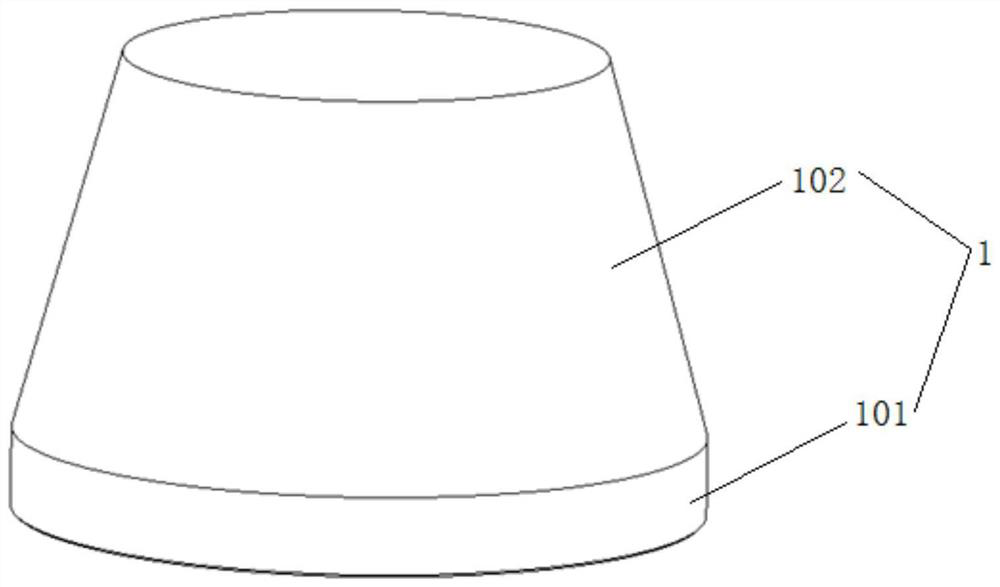

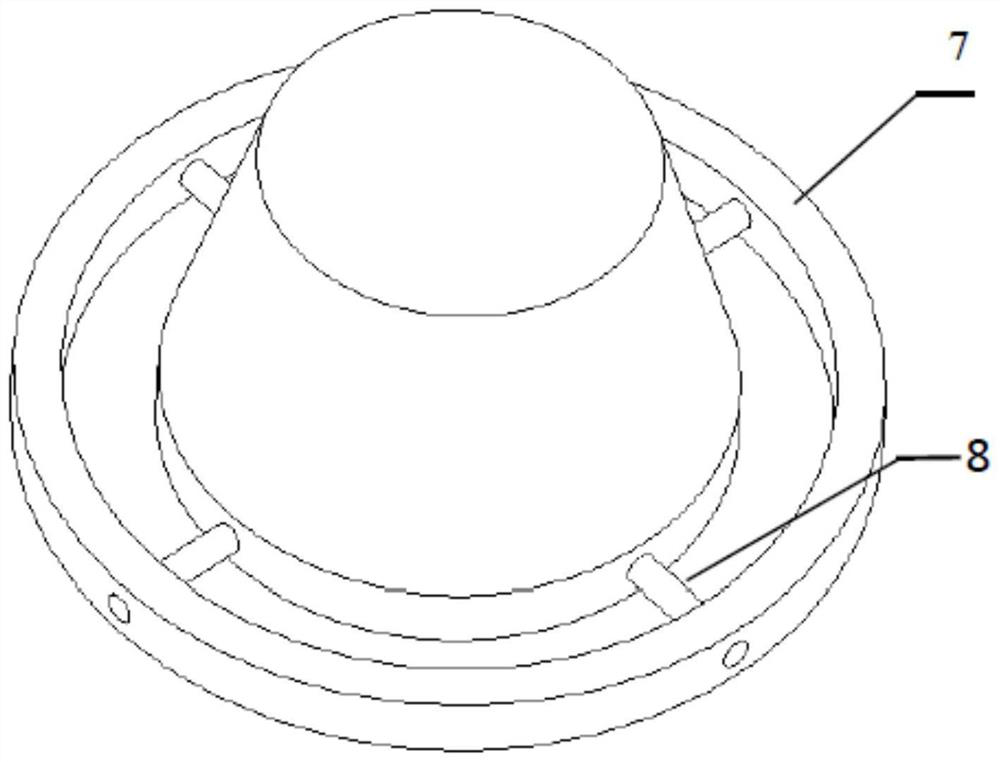

[0047] The arc ignition system includes an arc ignition controller 6 , an arc ignition electrode 7 , and an arc ignition needle 8 . The arc starting electrode 7 is ring-shaped, coaxial with the cathode, and fixed on the edge of the cathode target with a gap between them. The arc starting needle 8 made of insulating material coated with a conductive layer is connected to the end cylindrical section 101 of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com