Single-mold casting machine capable of tilting at 90 degrees to form aluminum piston workblanks through pouring and use method of single-mold casting machine capable of tilting at 90 degrees to form aluminum piston workblanks through pouring

A casting machine and blank technology, which is applied in foundry workshops, casting equipment, casting molding equipment, etc., can solve the problems of poor metallographic structure of piston blanks, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

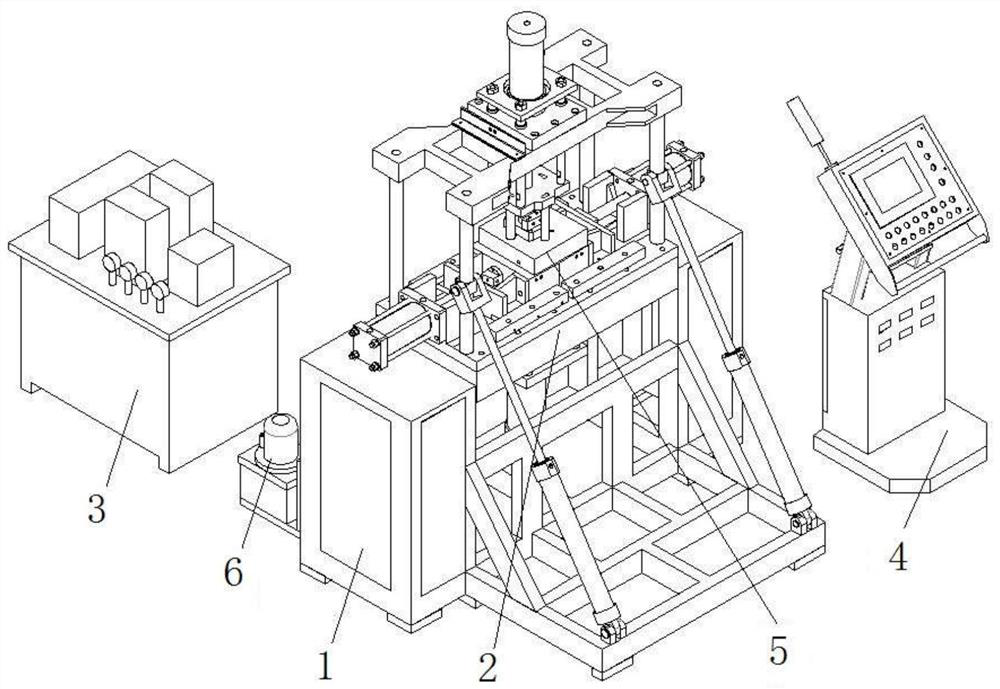

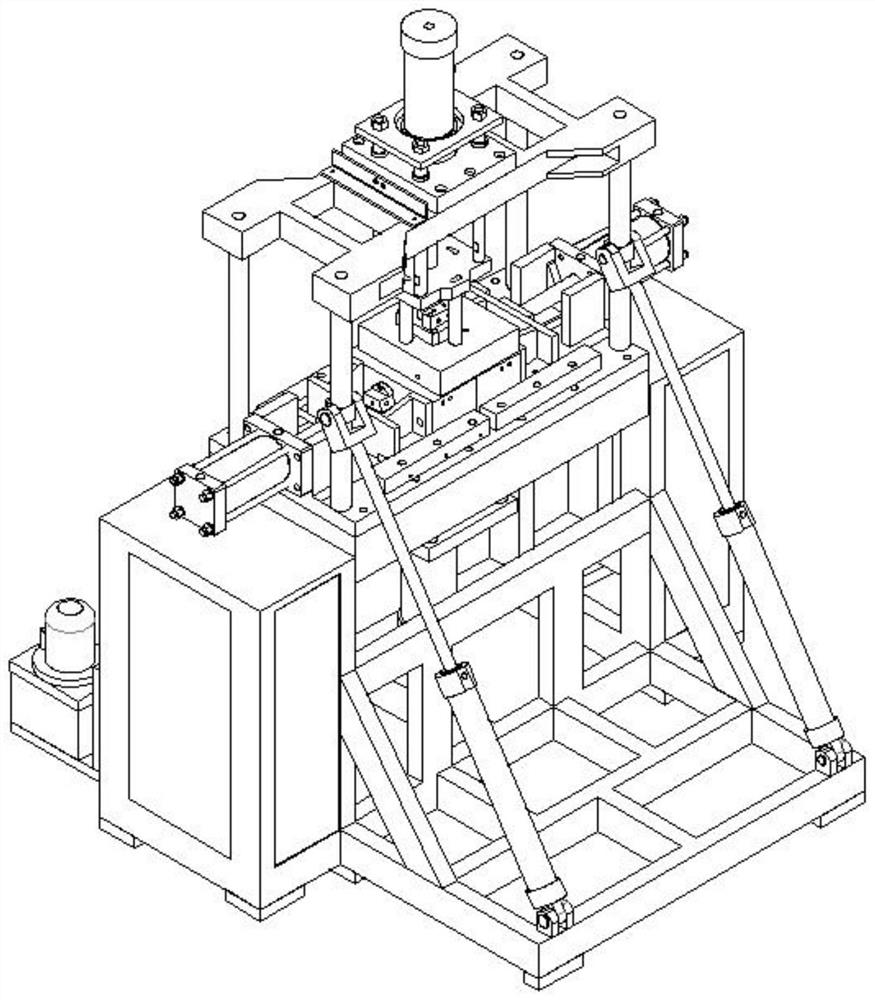

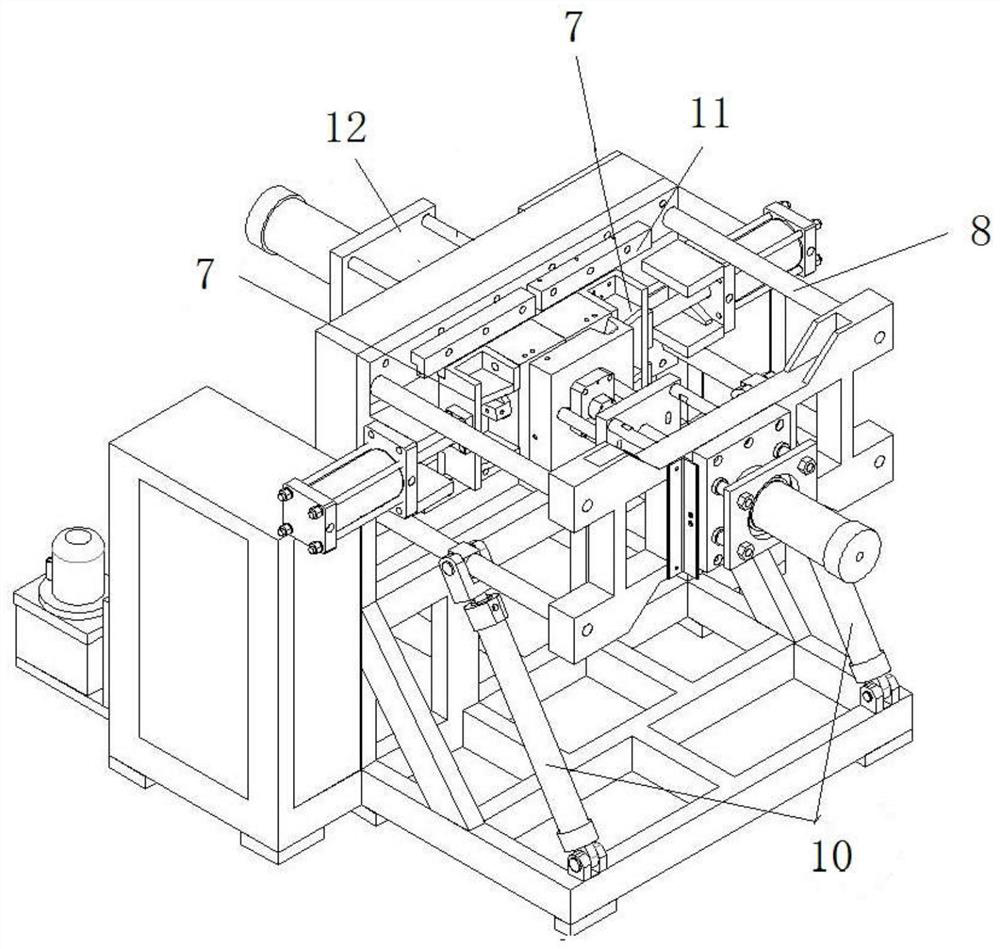

[0042] Such as Figure 1-7 As shown, this embodiment provides a single-mode casting machine for pouring aluminum piston blanks by tilting 90°, including a frame 1, a workbench 2, a tilting cylinder 10, a pouring system 5, a hydraulic system 3 and an electrical system 4, wherein , a workbench 2 is set on the frame 1, and a pouring system 5 is set on the workbench 2, and the piston blank is poured by passing aluminum liquid into the pouring system 5, and tilting cylinders 10 are respectively set on both sides of the bottom of the frame 1, and the tilting cylinders The other end of 10 is connected to the workbench 2, the tilting cylinder 10 and the pouring system 5 are both connected to the hydraulic system 3, and the hydraulic system 3 is connected to the electrical system 4.

[0043] The workbench 2 includes an upper base plate and a lower base plate, the upper base plate and the lower base plate are connected by four columns 8, the two sides of the lower base plate are connect...

Embodiment 2

[0061] A single-mode casting machine for pouring aluminum piston blanks with a tilt of 90°. The structure is as described in Embodiment 1. The difference is that temperature sensors are respectively set on the upper tooling, lower tooling, left tooling and right tooling, and the temperature sensors are connected to The electrical system detects the pouring temperature through the temperature sensor, and gives an alarm when the temperature is not up to standard, so as to ensure the solidified grain structure of the piston blank.

Embodiment 3

[0063] A single-mode casting machine for pouring aluminum piston blanks by tilting 90°, the structure is as described in Embodiment 1, the difference is that a suction device 6 is arranged on the frame 1, and the suction device 6 is connected to a salt core support rod 18 , absorb the gas generated by the heating of the salt core through the suction device, and reduce the porosity of the piston blank.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com