Bioretention composite media filler, preparation method thereof, and bioretention facility

A composite medium, bioretention technology, applied in chemical instruments and methods, biological water/sewage treatment, granular microbial carrier treatment, etc., can solve the problem that the removal rate of pollutants is greatly affected by seasons and changes in water quality and water quality, and the cost of fillers is high. , large area and other problems, to achieve strong selective ion exchange capacity, good water absorption and water retention, and improve the effect of water retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

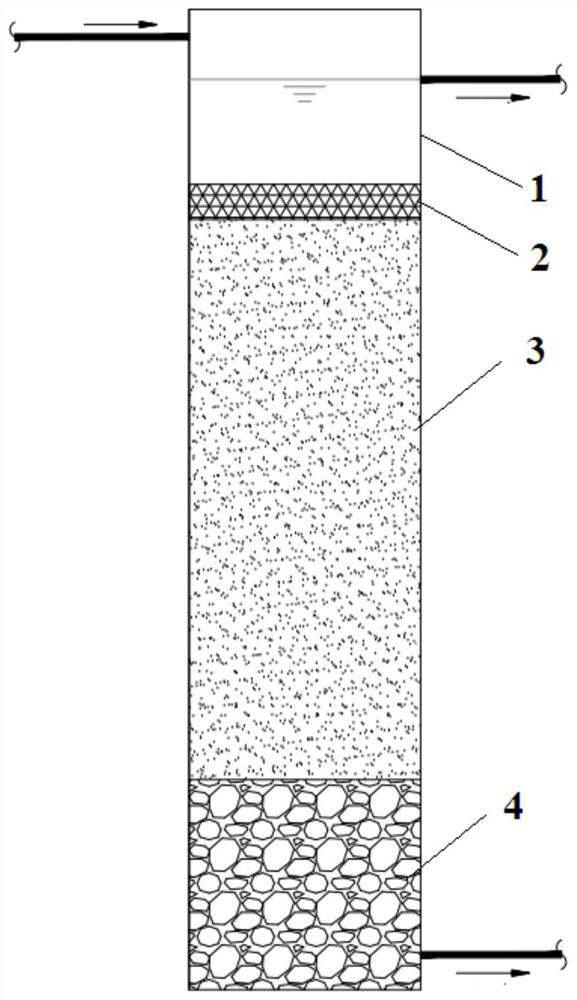

Image

Examples

preparation example Construction

[0043] According to another aspect of the present invention, there is also provided a method for preparing a bioretention composite media filler, comprising the following steps:

[0044] S1: Spread out the sludge dehydrated to 60% in the water supply plant and dry it in the sun, turn it once a day, and turn it continuously for 5 to 7 days;

[0045] S2: Pulverize and sieve the water supply plant sludge dried in step S1 to obtain water supply plant sludge particles;

[0046] S3: Soak the coconut bran that has been removed from the coconut shell in water, drain the remaining water when the volume expands to 3 to 4 times, then rinse the coconut bran while draining, repeatedly wash at least 3 times to remove the salt, and dry;

[0047] S4: Stir and mix the sludge particles from the water supply plant obtained in step S2 and the coconut peat obtained in step S3 with coarse sand, fine sand, and planting soil to obtain a bioretention composite medium filler.

[0048] The preparation ...

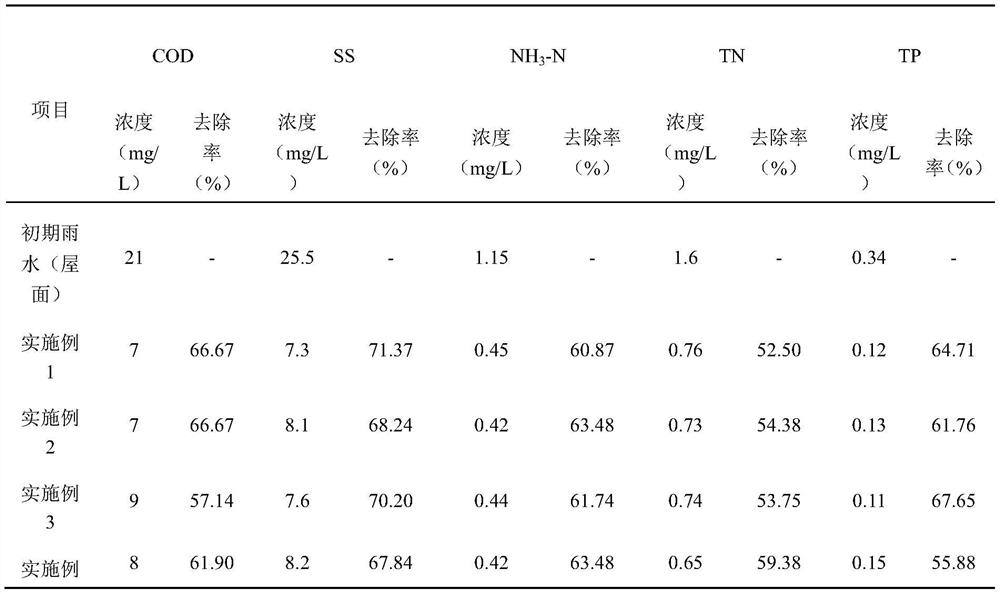

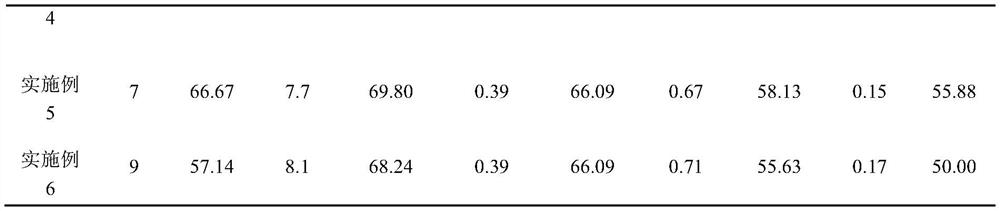

Embodiment 1

[0063] Bioretention composite media filler, including the following mass percentages: 5% of sludge from water supply plant, 54% of coarse sand, 13.5% of fine sand, 22.5% of planting soil, 5% of coconut peat, and the initial infiltration rate of bioretention composite media filler is ≥4.2 ×10 -5 m / s, stable infiltration rate ≥ 2.2×10 -5 m / s, pH is 6.3, organic matter loss on ignition (LOI) is 3.2%, coarse sand average particle size is 0.8mm, fineness modulus is 3.5; fine sand average particle size is 0.3mm, fineness modulus is 2 ;Permeability of planting soil >3.5×10 -6 m / s, organic content > 5%, pH value 7.1, cation exchange capacity > 5mep / 100g; coconut bran pH value 5.5, coconut bran EC value (conductivity) 0.6.

[0064] A method for preparing a bioretention composite media filler, comprising the following steps:

[0065] S1: Spread the sludge dehydrated to 60% from the water supply plant to form a 20cm thick mud layer and dry it in the sun. Use a soil tiller to turn the ...

Embodiment 2

[0071] Bioretention composite media filler, including the following mass percentages: 5% of sludge from water supply plant, 54% of coarse sand, 13.5% of fine sand, 22.5% of planting soil, 5% of coconut peat, and the initial infiltration rate of bioretention composite media filler is ≥4.2 ×10 -5 m / s, stable infiltration rate ≥ 2.2×10 -5 m / s, pH is 6.3, organic matter loss on ignition (LOI) is 3.2%, coarse sand average particle size is 0.8mm, fineness modulus is 3.5; fine sand average particle size is 0.3mm, fineness modulus is 2 ;Permeability of planting soil >3.5×10 -6 m / s, organic matter content > 5%, pH value 7.1, cation exchange capacity > 5mep / 100g; coconut bran pH value 6, coconut bran EC value (conductivity) is 0.75.

[0072] The preparation method of the bioretention composite media filler is the same as that in Example 1.

[0073] The bioretention facility is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com