Semi-hydrated and undisturbed phosphogypsum-based composite cementing material and preparation method thereof

A technology of composite cementitious material and phosphogypsum hemihydrate, which is applied in clay preparation equipment, chemical instruments and methods, cement mixing equipment, etc., can solve the problem of low utilization rate of phosphogypsum, high energy consumption, and difficulty in meeting the resource utilization of phosphogypsum And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

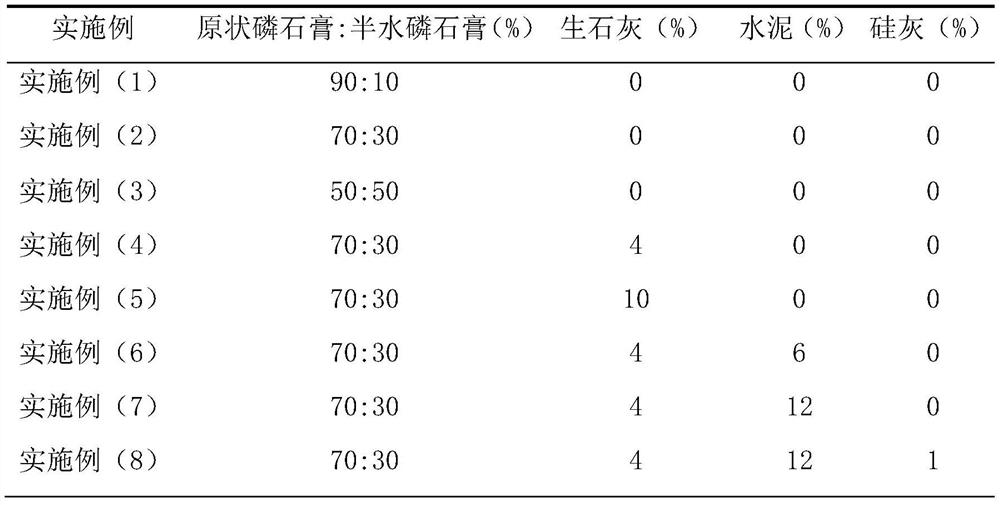

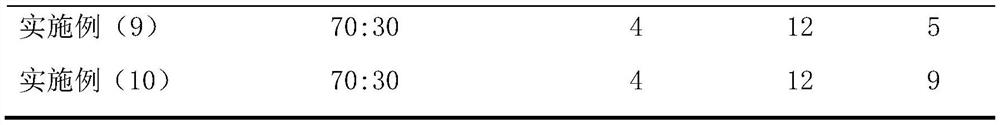

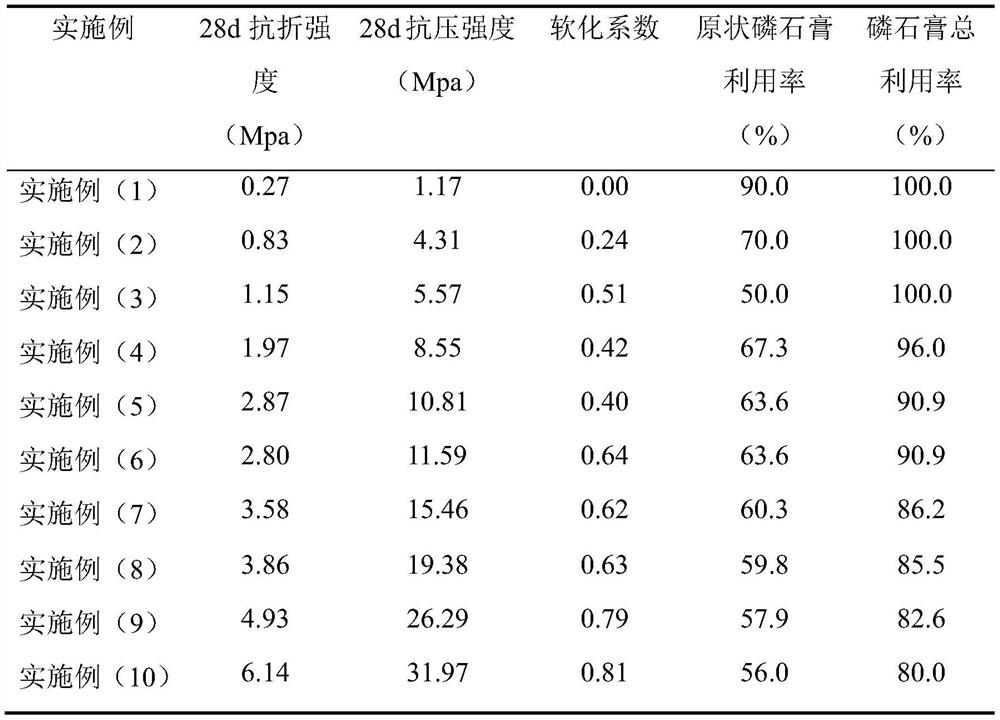

Embodiment 1

[0031] Embodiment 1: A semi-hydrated and undisturbed phosphogypsum-based composite cementitious material, the main raw material: the mixing ratio of the gypsum-based composite cementitious material is undisturbed phosphogypsum: hemihydrated phosphogypsum=90:10.

[0032] The undisturbed phosphogypsum has the phenomenon of agglomeration and agglomeration. In this embodiment, it is naturally air-dried to a moisture content of 8.9%, crushed by a 5mm sieve crusher, and further passed through a 0.315mm square hole sieve. The main component CaSO 4 2H 2 O.

[0033] The hemihydrate phosphogypsum is prepared by baking the undisturbed phosphogypsum in an oven at 160°C for 2 hours, and then naturally cooling to room temperature. The main component is CaSO 4 0.5H 2 O and a small part of CaSO 4 .

Embodiment 2

[0034] Example 2: A hemihydrate and original phosphogypsum-based composite gelling material, the main raw material: the mixing ratio of the phosphogypsum-based composite gelling material is original phosphogypsum:hemihydrate phosphogypsum=70:30.

[0035] The undisturbed phosphogypsum has the phenomenon of agglomeration and agglomeration. In this embodiment, it is naturally air-dried to a moisture content of 8.9%, crushed by a 5mm sieve crusher, and further passed through a 0.315mm square hole sieve. The main component CaSO 4 2H 2 O.

[0036] The hemihydrate phosphogypsum is prepared by baking the undisturbed phosphogypsum in an oven at 160°C for 2 hours, and then naturally cooling to room temperature. The main component is CaSO 4 0.5H 2 O and a small part of CaSO 4 .

Embodiment 3

[0037] Example 3: A semi-hydrated and original phosphogypsum-based composite gelling material, the main raw material: the mixing ratio of the phosphogypsum-based composite gelling material is original phosphogypsum: hemihydrate phosphogypsum=50:50.

[0038]The undisturbed phosphogypsum has the phenomenon of agglomeration and agglomeration. In this embodiment, it is naturally air-dried to a moisture content of 8.9%, crushed by a 5mm sieve crusher, and further passed through a 0.315mm square hole sieve. The main component CaSO 4 2H 2 O.

[0039] The hemihydrate phosphogypsum is prepared by baking the undisturbed phosphogypsum in an oven at 160°C for 2 hours, and then naturally cooling to room temperature. The main component is CaSO 4 0.5H 2 O and a small part of CaSO 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com