Yttrium-stabilized zirconium oxide hafnium powder for thermal spraying and preparation method thereof

A technology of yttrium-stabilized zirconia and thermal spraying, which is applied in the field of thermal spraying material preparation technology, can solve the problems of high cost, low output, and high production cost of hafnium oxide-based thermal barrier coatings, so as to reduce raw material costs, reduce hard agglomeration, The effect of increasing the service temperature of the coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

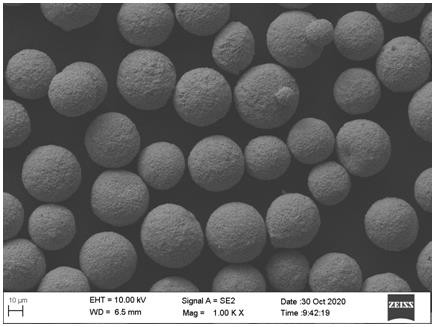

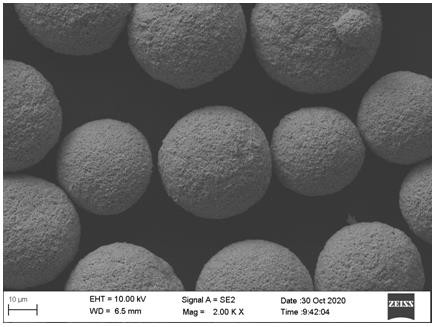

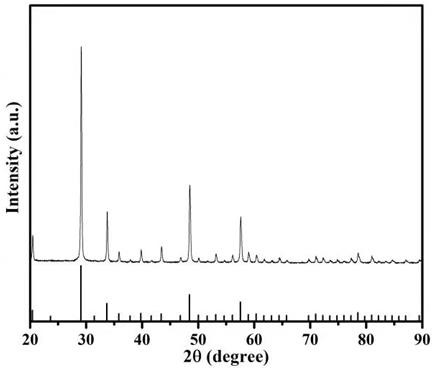

[0027] Embodiment 1: a kind of yttrium-stabilized zirconium hafnium oxide powder and its preparation method for thermal spraying, its steps are as follows:

[0028] 1) Preparation of yttrium-stabilized zirconium hafnium oxide precursor: according to the addition of yttrium source, Y 2 o 3 Metering and addition of hafnium source are based on HfO 2 Metering, zirconium source addition amount is ZrO 2 Metering, according to the weight ratio Y 2 o 3 :Zr(Hf)O 2 =7.8:92.2 and weight ratio HfO 2 :ZrO 2 =1:4 Put zirconium sulfate, hafnium tetrachloride and yttrium sulfate (50 Kg in total as oxides) into a batching tank with 750 L of pure water and stir evenly, then add pure water to 900 L to obtain yttrium , zirconium, hafnium mixed material liquid, the mixed material liquid is transferred to the charging tank after being filtered by filter cloth; the yttrium, zirconium and hafnium mixed material liquid in the charging tank is put into 25 wt% ammonium bicarbonate solution under ...

Embodiment 2

[0031] Embodiment 2: a kind of yttrium-stabilized zirconium hafnium oxide powder and its preparation method for thermal spraying, its steps are as follows:

[0032]1) Preparation of yttrium-stabilized zirconium hafnium oxide precursor: according to the addition of yttrium source, Y 2 o 3 Metering and addition of hafnium source are based on HfO 2 Metering, zirconium source addition amount is ZrO 2 Metering, according to the weight ratio Y 2 o 3 :Zr(Hf)O 2 =7.5:92.5 and weight ratio HfO 2 :ZrO 2 =1:5 Put zirconium oxychloride, hafnium oxychloride and yttrium chloride (50 Kg in total as oxides) into a batching tank with 750 L of pure water and stir evenly, then add pure water to 900 L obtains yttrium, zirconium, hafnium mixed material liquid, and the mixed material liquid is transferred to the charging barrel after being filtered by filter cloth; The yttrium, zirconium, hafnium mixed material liquid in the charging barrel is dropped into 25 wt% carbonic acid under stirring...

Embodiment 3

[0035] Embodiment 3: a kind of yttrium-stabilized zirconium hafnium oxide powder and its preparation method for thermal spraying, its steps are as follows:

[0036] 1) Preparation of yttrium-stabilized zirconium hafnium oxide precursor: according to the addition of yttrium source, Y 2 o 3 Metering and addition of hafnium source are based on HfO 2 Metering, zirconium source addition amount is ZrO 2 Metering, take the weight ratio HfO 2 :ZrO 2 =1:3.5 Adjust the extraction conditions of the zirconium and hafnium extraction and separation production line. 2 o 3 :Zr(Hf)O 2 =8:92 Put the yttrium feed liquid obtained from the rare earth yttrium production line into the batching tank and stir evenly, then add pure water to 900 L to obtain the mixed feed liquid of yttrium, zirconium, and hafnium (the three are converted into oxides to measure a total of 50 kg), the mixture After the liquid is filtered through the filter cloth, it is transferred to the charging tank; the mixed li...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com