Preparation method of tin antimony oxide nanopowder

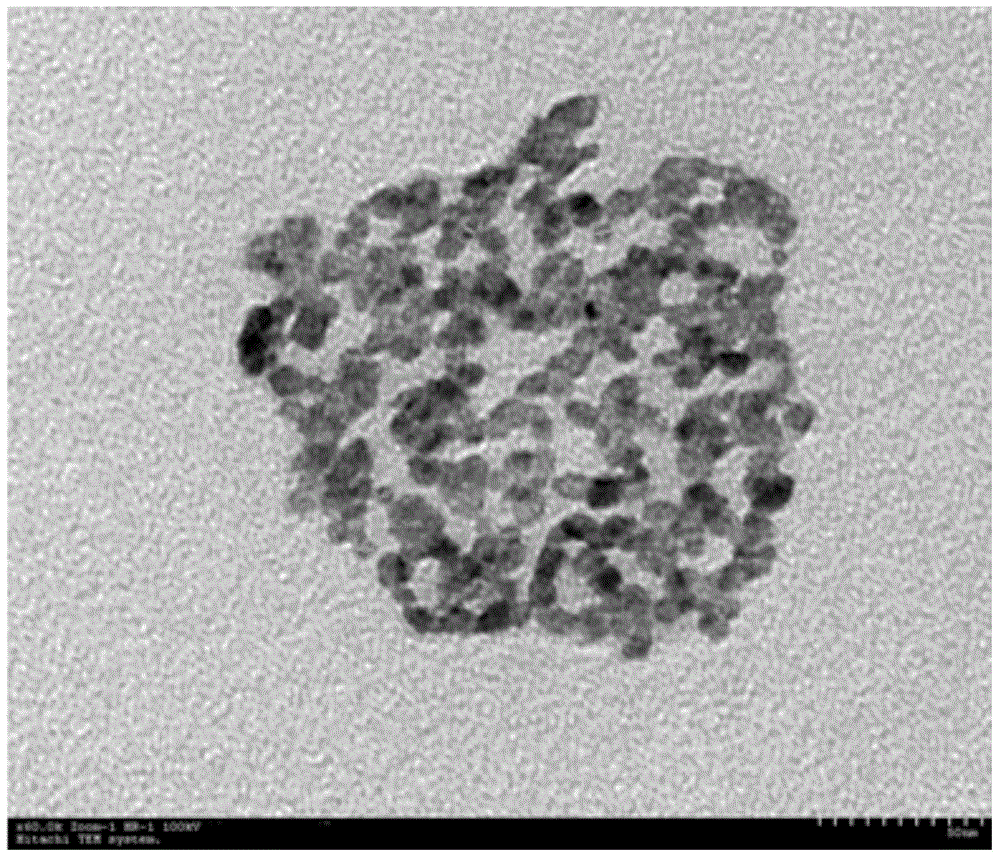

A nano-powder and antimony tin oxide technology is applied in the field of preparation of tin and antimony oxide nano-powder, which can solve the problems of low purity of nano-powder, easy agglomeration between particles, wide particle size distribution, etc., and achieve excellent optical properties. and electrical properties, the elimination of hydrogen bonds, the effect of narrow distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] 13.84g SnCl 4 And 3.13g SbCl 3 Dissolve in 65mL of anhydrous ethanol solution to obtain a colorless and transparent tin-antimony mixed solution. Mix 7.0g of ammonium bicarbonate with 70.0g of anhydrous ethanol solution to make a slurry, then dissolve 0.1g of ammonium acetate in a small amount of ethanol and add it to the dispersion, A solid-liquid suspension mixed solution is obtained. Under stirring conditions, the tin-antimony solution and the solid-liquid suspension were mixed and reacted. The reaction temperature was 5°C, the pH value was 5, and the reaction time was 2.0h to obtain white milky Sn(OH) 4 And NH 4 The Cl mixture precipitated. After filtration and vacuum drying at 40°C, after recovering the ethanol, the filter cake was dissolved and dispersed with 70.0g deionized water, filtered, washed with deionized water until no chloride ions were detected, and then dehydrated with absolute ethanol. Vacuum drying at 90℃ to obtain white powdery Sn(OH) 4 The precursor ...

Embodiment 2

[0029] 10.70g SnCl 4 And 2.35g SbCl 3 Dissolve in 35mL of anhydrous ethanol solution to obtain a colorless and transparent tin-antimony mixed solution. Mix 9.0g of ammonium bicarbonate with 50.0g of anhydrous ethanol solution to make a slurry, and then dissolve 0.6g of ammonium acetate in a small amount of ethanol and add to it, disperse, A solid-liquid suspension mixed solution is obtained. Under stirring conditions, the tin-antimony solution and the solid-liquid suspension were mixed and reacted. The reaction temperature was 15°C, the pH value was 6, and the reaction time was 3.5 hours to obtain white milky Sn(OH) 4 And NH 4 The Cl mixture precipitated. After filtering, drying in vacuum at 60°C, and recovering ethanol, the filter cake is dissolved and dispersed with 110.0g deionized water, filtered, washed with deionized water until no chlorine ions are detected, and then dehydrated with absolute ethanol. Vacuum drying at 80℃ to obtain white powdery Sn(OH) 4 The precursor was...

Embodiment 3

[0032] 16.43g SnCl 4 And 0.78g SbCl 3 Dissolve in 65mL of anhydrous ethanol solution to obtain a colorless and transparent tin-antimony mixed solution. Mix 14.0g of ammonium bicarbonate with 35.0g of anhydrous ethanol solution to make a slurry, then dissolve 0.6g of ammonium acetate in a small amount of ethanol and add to it to disperse. A solid-liquid suspension mixed solution is obtained. Under stirring conditions, the tin-antimony solution and the solid-liquid suspension were mixed and reacted. The reaction temperature was 25°C, the pH value was 8, and the reaction time was 4.0 hours to obtain white milky Sn(OH) 4 And NH 4 The Cl mixture precipitated. After filtration and vacuum drying at 70°C, after recovering ethanol, the filter cake was dissolved and dispersed with 90.0g deionized water, filtered and washed with deionized water until no chloride ions were detected, and then dehydrated with absolute ethanol. Vacuum drying at 60℃ to obtain white powdery Sn(OH) 4 The precurs...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| bulk density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com