Alkali metal-rare earth ternary sulfide nano luminescent material, preparation method and application thereof

A nano-luminescent material and ternary sulfide technology, applied in the direction of luminescent materials, nano-optics, chemical instruments and methods, etc., to achieve the effects of good dispersion, easy control of synthesis conditions, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

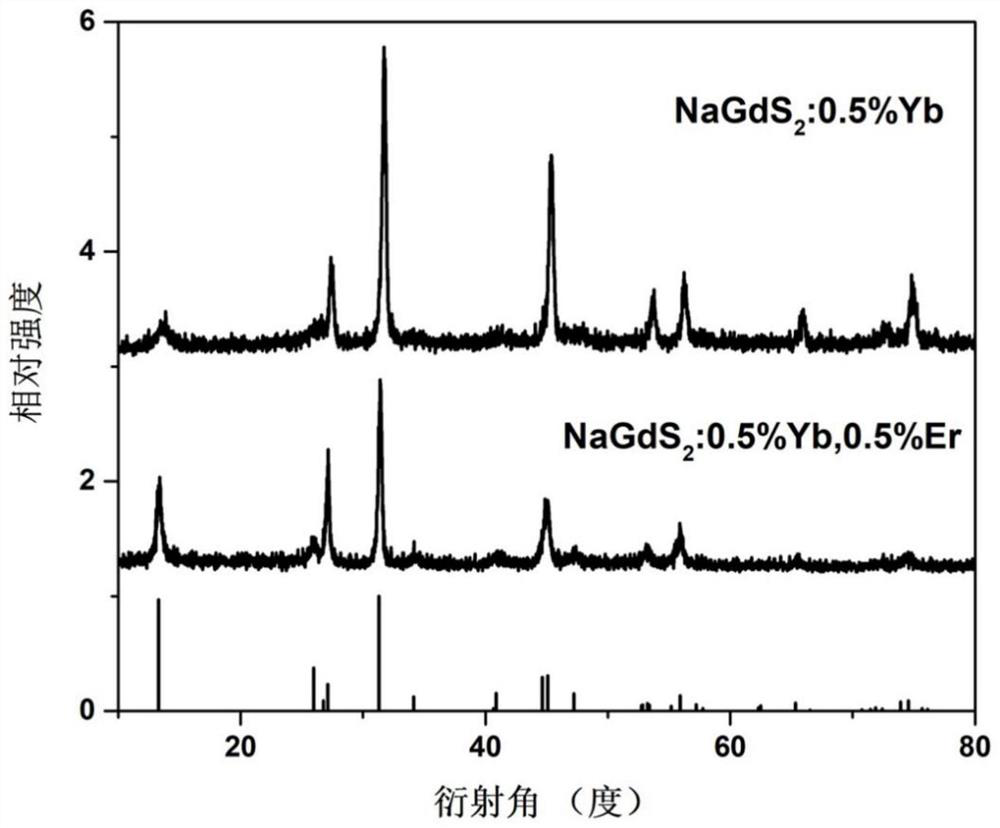

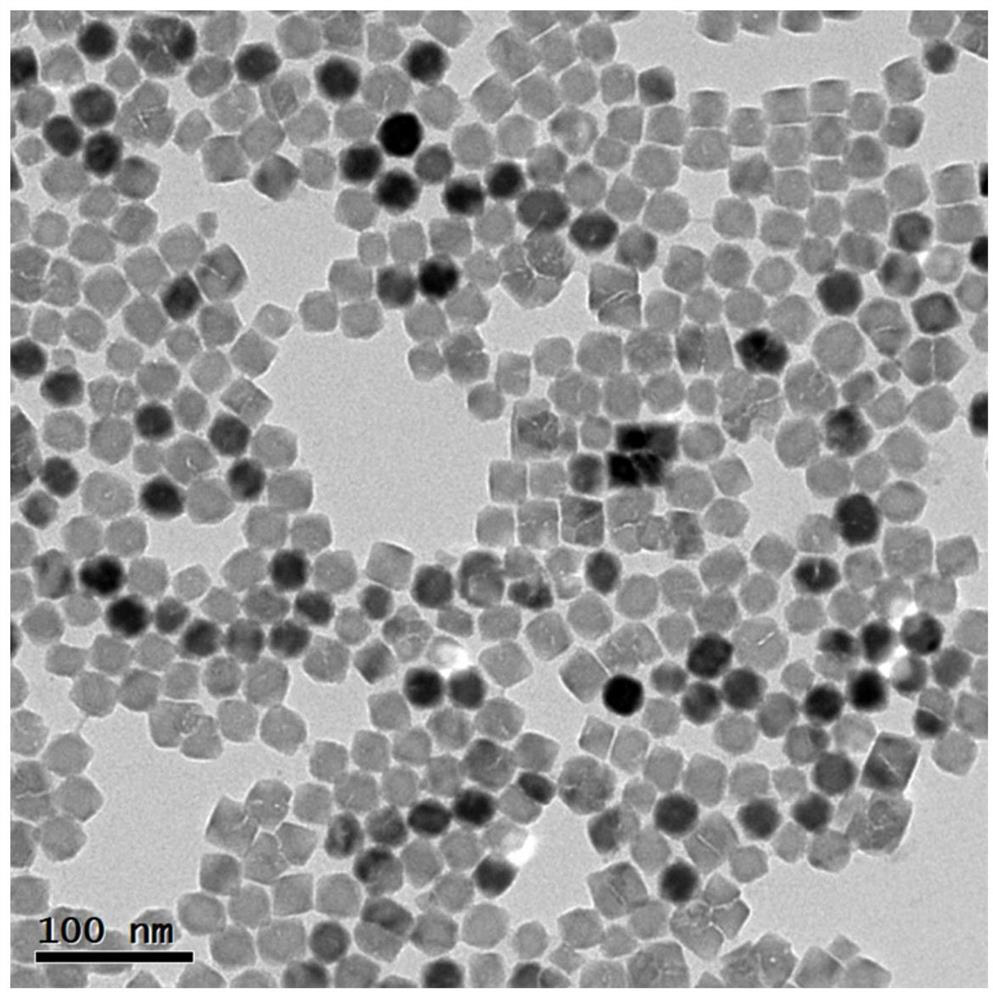

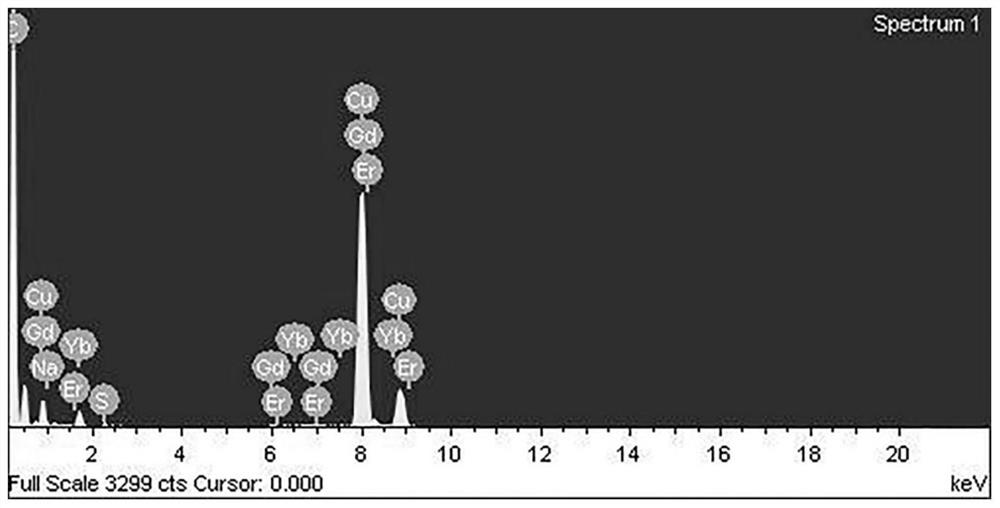

[0035] Example 1: NaGdS 2 :0.5mmol%Yb 3+ / 0.5mmol%Er 3+ Preparation of nanoparticles

[0036] Weigh 2mmol CH at room temperature 3 COONa, 0.99mmol Gd(CH 3 COO) 3 4H 2 O, 0.005mmol Yb(CH 3 COO) 3 4H 2 O and 0.005mmol Er(CH 3 COO) 3 4H 2O. Add 4mL oleic acid, 8mL oleylamine and 8mL octadecene, mix evenly, heat up to dissolve under nitrogen atmosphere, stir evenly, cool down to room temperature, add 4mmol thiourea in absolute ethanol, drain ethanol at 80°C, under nitrogen atmosphere Raise the temperature to 280°C, keep it warm for 1h, and then drop to room temperature. Precipitation and centrifugal washing with ethanol can obtain oil-soluble NaGdS with good dispersion 2 :0.5mmol%Yb 3+ / 0.5mmol%Er 3+ nanoparticles.

Embodiment 2

[0037] Example 2: NaGdS 2 :0.5mmol%Yb 3+ Preparation of nanoparticles

[0038] Weigh 2mmol CH at room temperature 3 COONa, 0.995mmol Gd(CH 3 COO) 3 4H 2 O and 0.005mmol Yb(CH 3 COO) 3 4H 2 O. Add 4mL oleic acid, 8mL oleylamine and 8mL octadecene, mix evenly, heat up to dissolve under nitrogen atmosphere, stir evenly, cool down to room temperature, add 4mmol thiourea in absolute ethanol, drain ethanol at 80°C, under nitrogen atmosphere Raise the temperature to 280°C, keep it warm for 1h, and then drop to room temperature. Precipitation and centrifugal washing with ethanol can obtain oil-soluble NaGdS with good dispersion 2 :0.5mmol%Yb 3+ nanoparticles.

Embodiment 3

[0039] Example 3: NaGdS 2 : 1 mmol% Sm 3+ Preparation of nanoparticles

[0040] Weigh 2mmol CH at room temperature 3 COONa, 0.99mmol Gd(CH 3 COO) 3 4H 2 O and 0.01mmol Sm(CH 3 COO) 3 4H 2 O. Add 4mL oleic acid, 8mL oleylamine and 8mL octadecene, mix evenly, heat up to dissolve under nitrogen atmosphere, stir evenly, cool down to room temperature, add 4mmol thiourea in absolute ethanol, drain ethanol at 80°C, under nitrogen atmosphere Raise the temperature to 280°C, keep it warm for 1h, and then drop to room temperature. Precipitation and centrifugal washing with ethanol can obtain oil-soluble NaGdS with good dispersion 2 : 1 mmol% Sm 3+ nanoparticles.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com