Preparation method of antibacterial plate for tableware

A technology for dining utensils and plates, applied in the field of metal rolling, can solve problems such as harmful substances in coated stainless steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

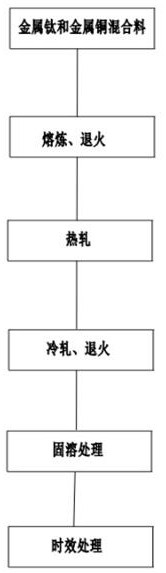

Image

Examples

Embodiment 1

[0026] This embodiment provides a kind of preparation method of bacteriostatic board material for catering utensils, comprising the following steps:

[0027] S1, get granular mass fraction and be 97% metallic titanium and be 3% metallic copper and mix, obtain compound;

[0028] S2, using a non-consumable vacuum arc melting furnace to melt into alloy ingots. During the vacuum melting process, the vacuum degree is controlled at 0.001Pa, the vacuum melting temperature is controlled at 1100°C, and electromagnetic stirring is used to assist production, heat preservation for 3 hours, and then annealed and cooled , the specific annealing temperature is 950°C, and the heat preservation is 8 hours; in order to ensure the uniform composition of the alloy, repeated melting can be carried out many times.

[0029] S3, heating the annealed and cooled ingot, and performing 2 passes of hot rolling to form a plate, the temperature range of the hot rolling is 800°C, to obtain a hot rolled plate...

Embodiment 2

[0056] The present embodiment provides a preparation method of antibacterial plates for catering utensils, comprising the following steps:

[0057] S1, get granular mass fraction and be 97% metallic titanium and be 3% metallic copper and mix, obtain compound;

[0058] S2, using a non-consumable vacuum arc melting furnace to melt into alloy ingots. During the vacuum melting process, the vacuum degree is controlled at 0.1Pa, the vacuum melting temperature is controlled at 1400°C, and electromagnetic stirring is used to assist production. The heat preservation is 6h, and then annealed and cooled. , the concrete annealing temperature is 1000 DEG C, heat preservation 10 hours;

[0059] S3, heating the annealed and cooled ingot, performing 2 passes of hot rolling to form a plate, the temperature range of the hot rolling is 880°C, and obtaining a hot rolled plate with a thickness of 2mm;

[0060] S4, cold rolling and annealing, performing multiple cold rolling and annealing treatmen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com