A kind of preparation method of powder embedding infiltration coating

A technology of powder embedding and infiltration coating, applied in the direction of coating, metal material coating process, solid diffusion coating, etc., to achieve the effect of prolonging high temperature service life, improving surface energy, improving diffusion speed and infiltration layer uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

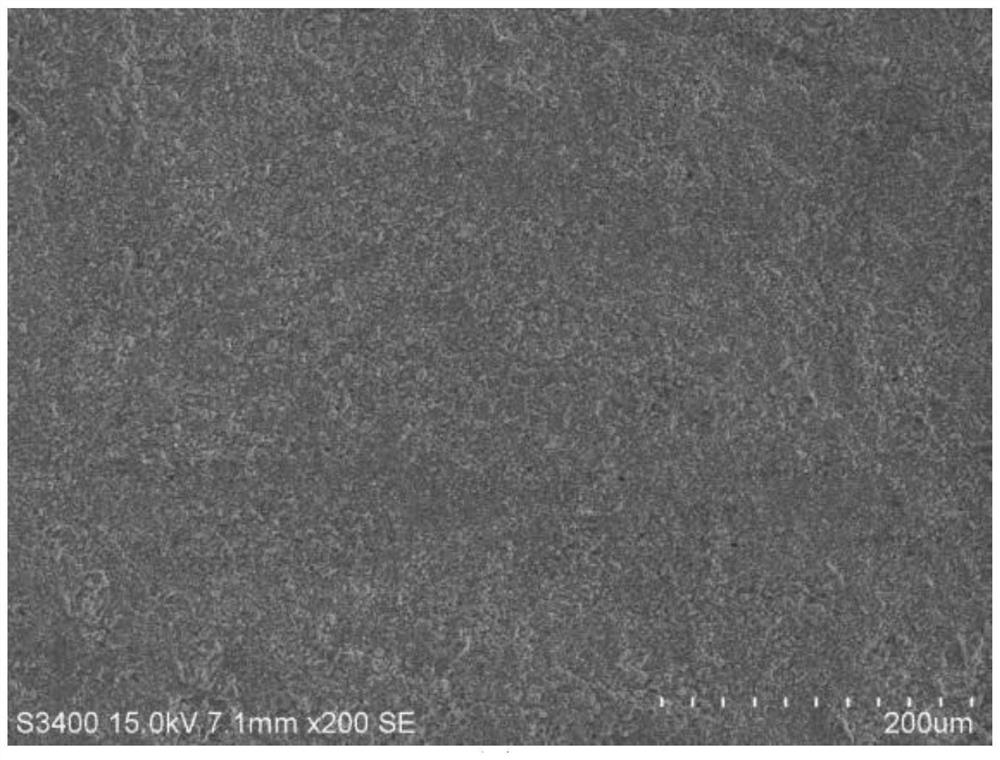

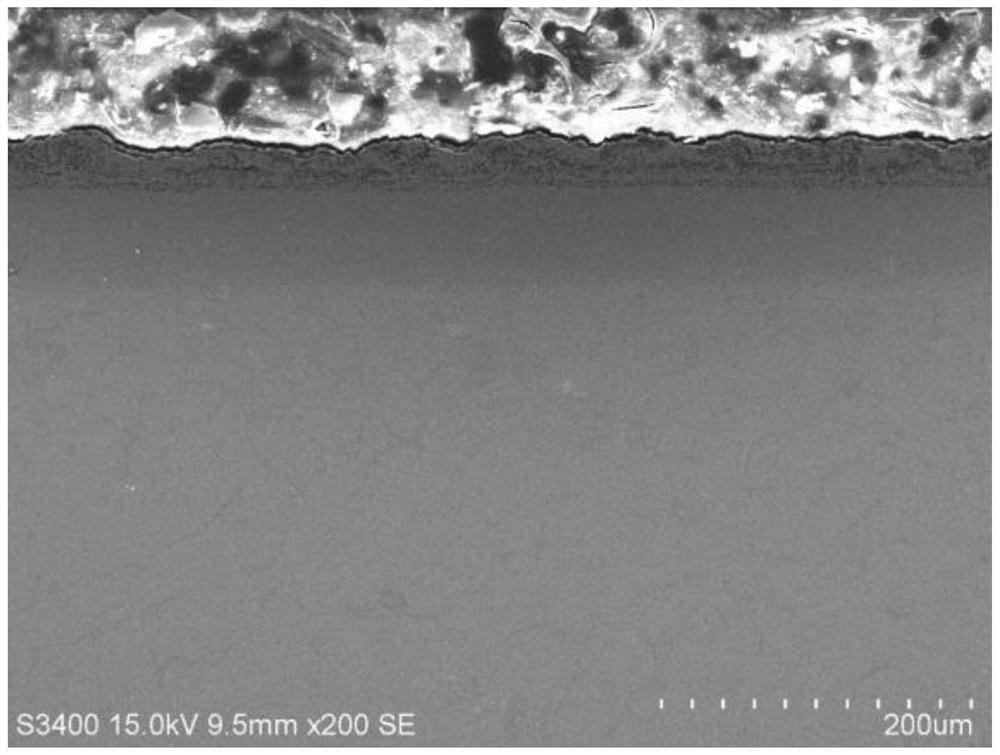

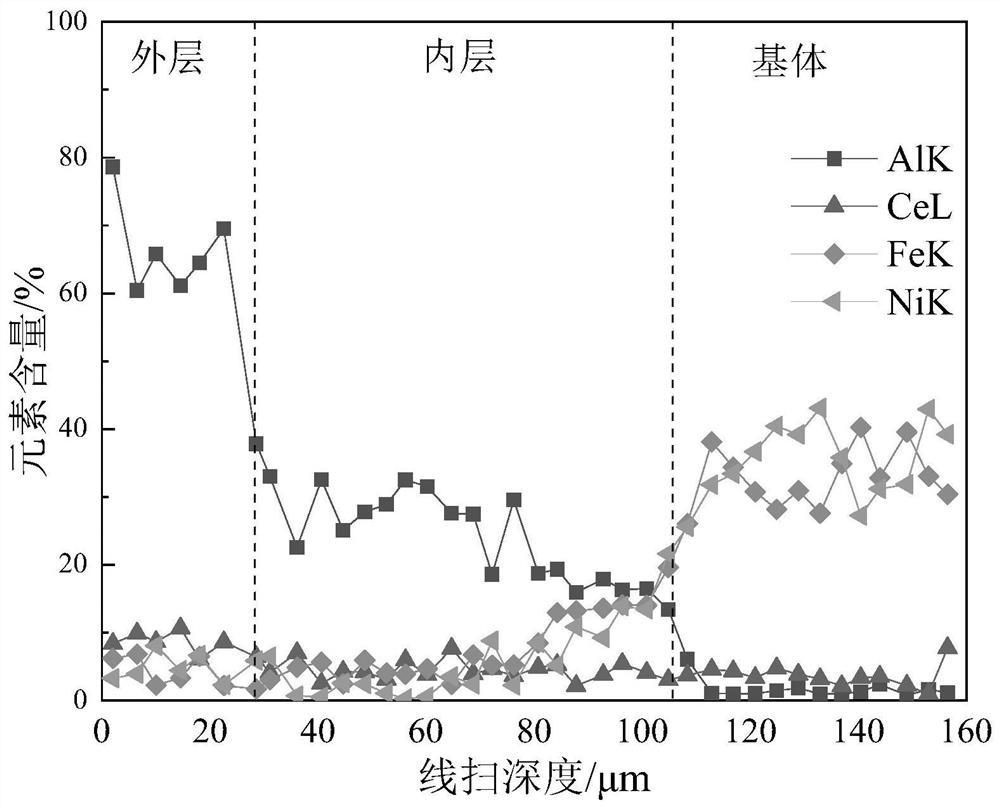

Image

Examples

Embodiment 1

[0025] The workpiece material is Cr25Ni35 alloy, and the coating preparation process is as follows:

[0026] Step (1): The co-infiltration agent (aluminum powder 45%, ammonium chloride: 2%; cerium rare earth 5%, silicon powder: 1%; graphite powder 0.2%; aluminum oxide: the balance) is weighed according to the proportion , Stir and mix it, put it into a ball mill for ball milling and mixing for 2 hours, the rotation speed is 300r / min, and the ball-to-material ratio is 1:2.

[0027] Step (2): Grind the workpiece to 2000# with silicon carbide sandpaper, and ultrasonically clean it with absolute ethanol.

[0028] Step (3): Embed the workpiece in the infiltration agent and compact it, and fill the connection between the infiltration box body and the box cover with high-temperature refractory mud, and then put it in an oven to dry at 80°C for 2 hours.

[0029] Step (4): Put the infiltration box in a heat treatment furnace, heat it at 10°C / min to 750°C for 5 hours, and take it out a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com