Seaweed and chlorella compound enzyme and preparation method thereof

A compound enzyme, chlorella technology, applied in the direction of bacteria, Streptococcus/Lactococcus, food science, etc. used in food preparation, can solve the problems of poor taste, low content of flavor substances, poor taste of seaweed fermentation, etc. To achieve the effect of high content of antioxidant nutrients, moderate total acid content, mellow and sweet taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1 flavor substance is determined

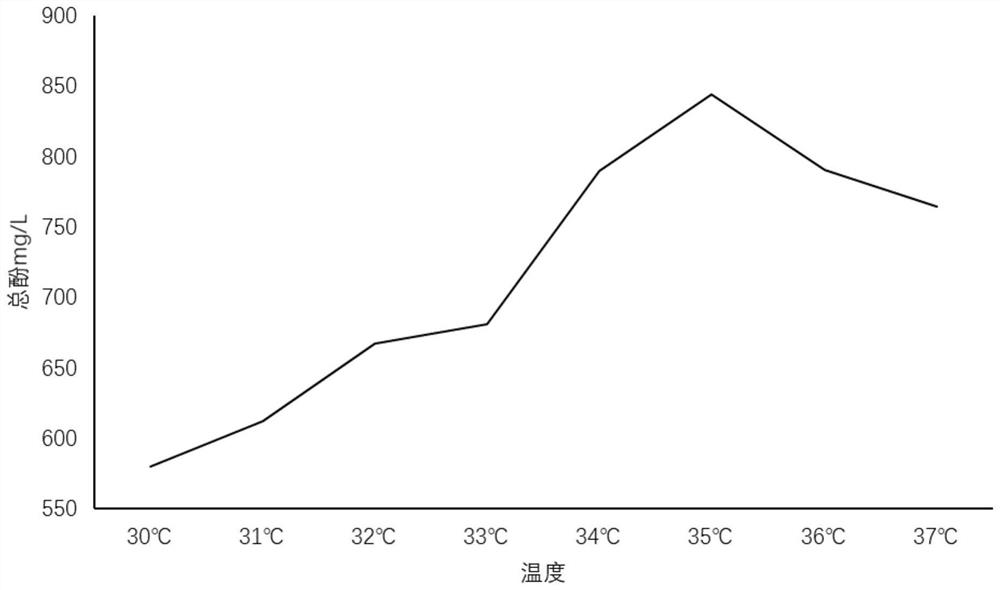

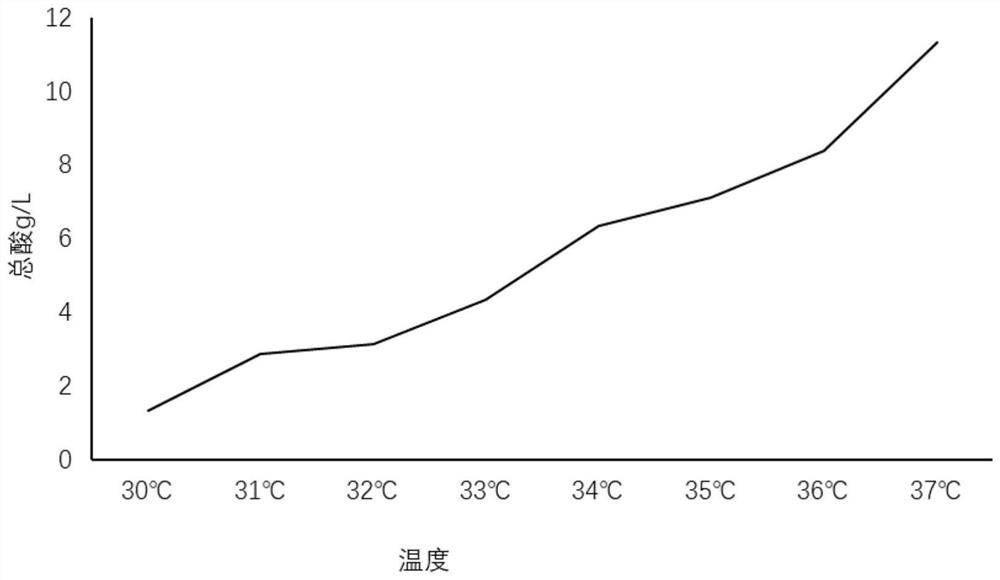

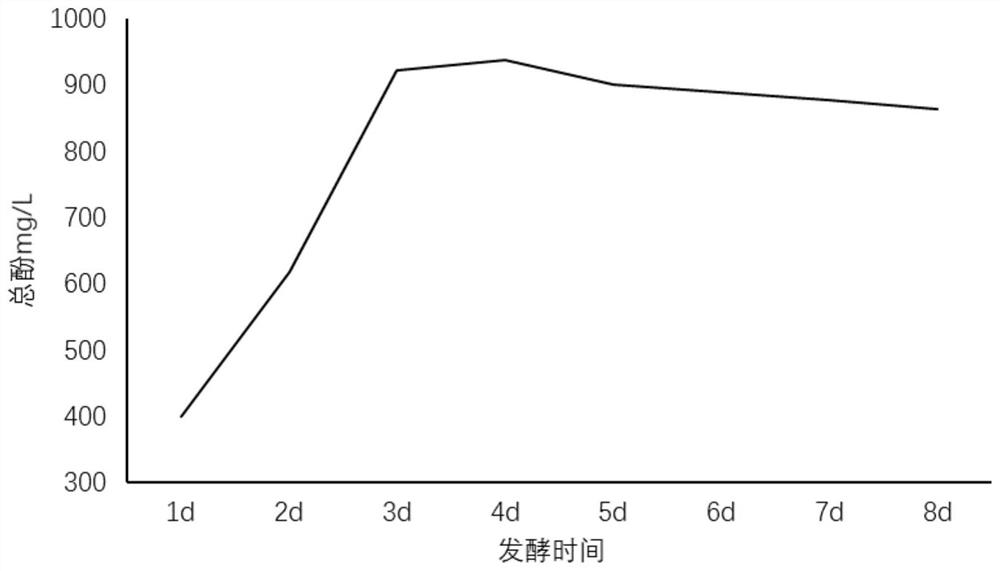

[0025] In fermentation practice, Streptococcus thermophilus is generally used to produce flavor substances. In this example, seaweed and chlorella are used as raw materials, and Streptococcus thermophilus is used as the fermentation strain to determine the flavor substances for fermentation. The fermentation process is as follows: clean Antarctic ice algae crushed to a particle size of less than 5mm, adding chlorella (the weight ratio of Antarctic ice algae to chlorella is 2:1), and mixing; then put the material into the water extraction equipment, adding 4 times the total weight of the material weight of water, the water extraction temperature is 80°C, and the extraction time is 40min. After extraction, filter, discard the filter residue, and obtain the filtrate; send the filtrate into the fermenter, add sucrose accounting for 5% of the filtrate mass, and insert Streptococcus thermophilus Bacterial solution (the number of v...

Embodiment 2

[0028] Embodiment 2 strain optimization

[0029] In order to improve the content of flavor substances in the fermented product, the inventors selected Streptococcus thermophilus (CGMCC 1.1855) and Lactobacillus plantarum (CGMCC 1.1856, group 1), Saccharomyces cerevisiae (CGMCC 2.3871, group 2), Lactobacillus bulgaricus (CGMCCNo. 7134, group 3), Bifidobacterium longum (CGMCC No.15028, group 4), Bacillus coagulans (CGMCC No.12553, group 5) composite fermentation (the control group was fermented by Streptococcus thermophilus single bacteria), the fermentation process is as follows : Crush the cleaned Antarctic ice algae until the particle size is less than 5mm, add chlorella (the weight ratio of Antarctic ice algae and chlorella is 2:1), and mix well; then put the material into the water extraction equipment, add chlorella Water with 4 times the weight of the total weight of the material, the water extraction temperature is 80 ° C, and the extraction time is 40 min. After extract...

Embodiment 3

[0035] Embodiment 3 Fermentation material optimization

[0036] In order to increase the content of flavor substances in the fermented product, the inventor selected chlorella and laver (group 1), Phaeodactylum tricornutum (group 2), kelp (group 3), Antarctic ice algae (group 4), carrageenan (Group 5) mixed fermentation according to the mass ratio of 1:2, and the control group was chlorella fermented alone. The fermentation process was as follows: the cleaned seaweed was crushed to a particle size of less than 5mm, added chlorella, and mixed; then the materials were put into In the water extraction equipment, add water that is 4 times the weight of the total weight of the material, the water extraction temperature is 80 ° C, the extraction time is 40 minutes, filter after extraction, discard the filter residue, and obtain the filtrate; send the filtrate into the fermentation tank, add the The sucrose of quality 5%, inserts saccharomyces cerevisiae bacterium liquid (the number ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com