Super-gravity regeneration energy-saving process of flue gas CO2 capture system

A super-gravity and super-gravity reactor technology, applied in the field of flue gas capture system, can solve the problem of high energy consumption of the regeneration system, achieve the effects of small investment, reduced chemical consumption, and reduced environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

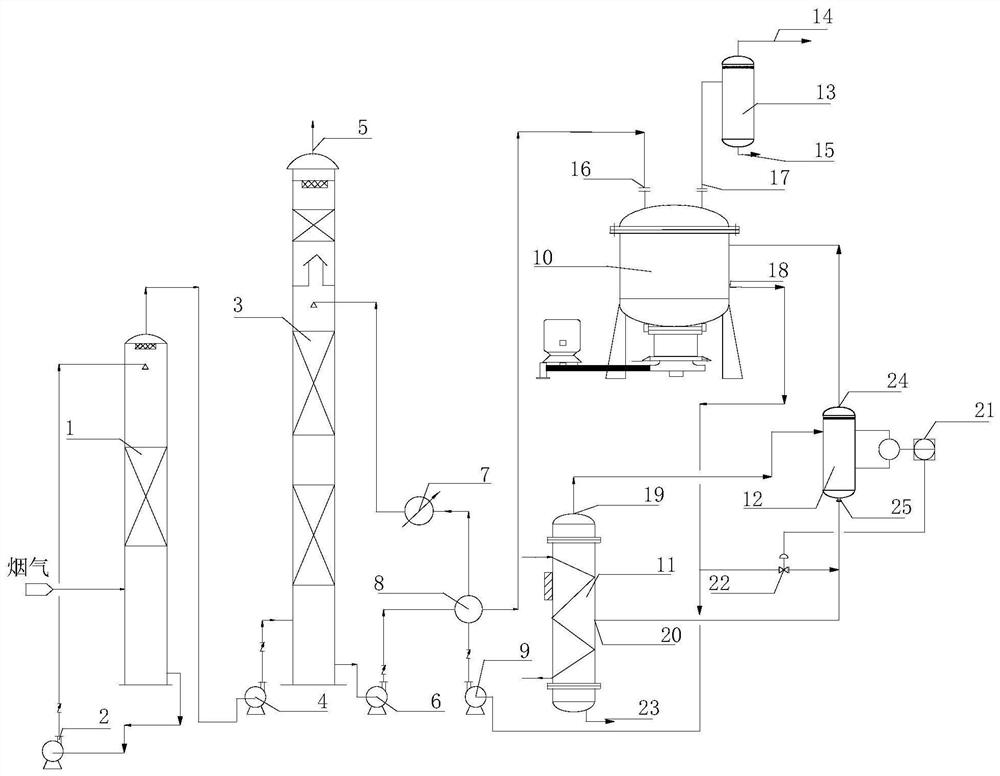

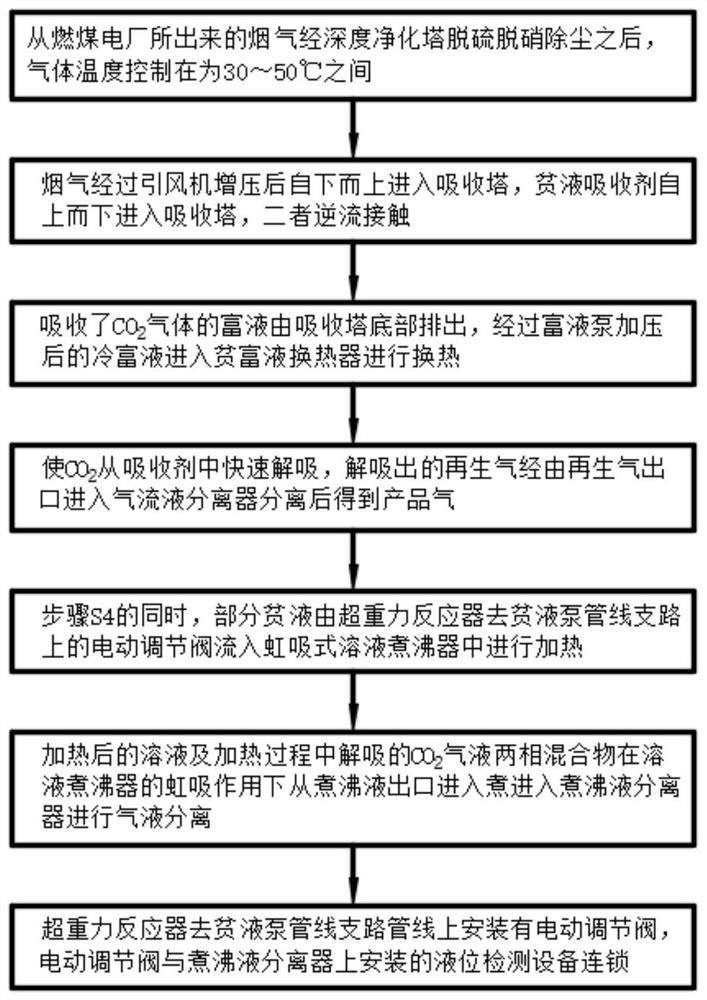

[0032] A flue gas CO 2 The high-gravity regeneration and energy-saving process of the capture system includes the following steps:

[0033] S1. After the flue gas from the coal-fired power plant is desulfurized, denitrated and dust-removed by the deep purification tower 1, the gas temperature is controlled between 30-50°C;

[0034] S2. The flue gas enters the absorption tower 3 from bottom to top after being pressurized by the induced draft fan 4, and the lean liquid absorbent enters the absorption tower 3 from top to bottom, and the two contact countercurrently to complete the CO 2 the absorption process;

[0035] S3, absorbed CO 2 The rich liquid of the gas is discharged from the bottom of the absorption tower, and the cold rich liquid pressurized by the rich liquid pump 6 enters the lean-rich liquid heat exchanger 8 for heat exchange, and sprays into the supergravity reactor 10 after heat exchange;

[0036] S4, making CO 2 Quickly desorb from the absorbent, and the deso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com