Repair material and preparation process thereof

A technology for preparing technology and repairing materials, which is applied in the field of repairing materials and its preparation technology, can solve problems such as reducing road maintenance costs, difficult road maintenance, and affecting mixing effects, and achieves improved chemical stability, good electrical insulation, and improved mixing. The effect of material efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

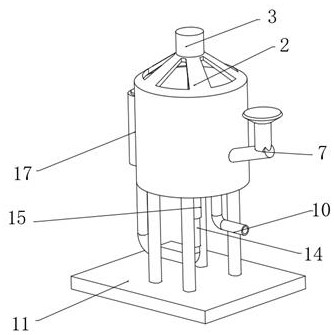

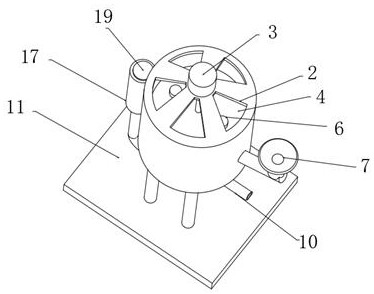

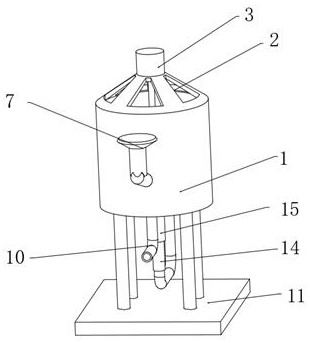

[0030] Such as Figure 1-5 Shown, a kind of restoration material and preparation technology thereof, S1: with waste polyvinyl chloride 50%; Polyurethane waste 20 parts; Polytetrafluoroethylene 15%; Calcium stearate 5%; Antioxidant 3%; 3% of the catalyst; 2% of the catalyst and 2% of the lead salt stabilizer are sent into the mixer, the heating temperature is set to 200°C, and the melting is accelerated under the action of the stirring shaft, and the speed is 600-900 rpm;

[0031] S2: The obtained mixture is fed from the main feeding port and the side feeding port of the twin-screw extruder respectively, and the mixture is mixed in a twin-screw extruder with a rotating speed of 400 to 600 rpm for 10 to 15 minutes;

[0032] S3: After the mixing is completed, the material is cooled and pelletized to obtain polyvinyl chloride regenerated plastic pellets.

[0033] As an embodiment of the present invention, the plasticizer is a maleic anhydride graft compatibilizer, and the lubrica...

Embodiment 2

[0039] Such as Figure 1-5 Shown, a kind of restoration material and preparation technology thereof, S1: with waste polyvinyl chloride 50%; Polyurethane waste 25 parts; Polytetrafluoroethylene 10%; Calcium stearate 5%; Antioxidant 3%; 3% of the catalyst; 2% of the catalyst and 2% of the lead salt stabilizer are sent into the mixer, the heating temperature is set to 200°C, and the melting is accelerated under the action of the stirring shaft, and the speed is 600-900 rpm;

[0040] S2: The obtained mixture is fed from the main feeding port and the side feeding port of the twin-screw extruder respectively, and the mixture is mixed in a twin-screw extruder with a rotating speed of 400 to 600 rpm for 10 to 15 minutes;

[0041] S3: After the mixing is completed, the material is cooled and pelletized to obtain polyvinyl chloride regenerated plastic pellets.

[0042] As an embodiment of the present invention, the plasticizer is a maleic anhydride graft compatibilizer, and the lubrica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com