Aluminum mold of auto engine and preparation method thereof

A technology for automobile engines and aluminum molds, which is applied in the direction of engine components, mechanical equipment, manufacturing tools, etc., and can solve problems such as poor quality of anti-corrosion treatment, complicated treatment process, and low treatment efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] A preparation method for an automobile engine aluminum mold, comprising the steps of:

[0046] (1) Preparation of polytetrafluoroethylene coating:

[0047] The specific implementation measures are

[0048] (1) Pretreat the aluminum mold, hang the parts to be plated, degrease and degrease, wash with water, and pickle and activate in sequence;

[0049] (2) The surface is polished to a roughness Ra of 0.3 μm, and deionized water is cleaned in ultrasonic waves;

[0050] (3) Put the parts to be plated into the pre-plating solution and soak for 30 minutes, nickel powder in the pre-plating solution: polytetrafluoroethylene = 2:1;

[0051] (4) Soak in hydrochloric acid solution with a volume concentration of 250mL / L for 12h;

[0052] (5) Configure the electroplating solution: include 2% short fiber, 15% nickel chloride, 5% sodium citrate, 35% nickel sulfate, 20% polytetrafluoroethylene particles, 2.5% vinyl fluoride, 5% of perfluoroalkyl compound, 5% of propylene copolymer,...

Embodiment 2

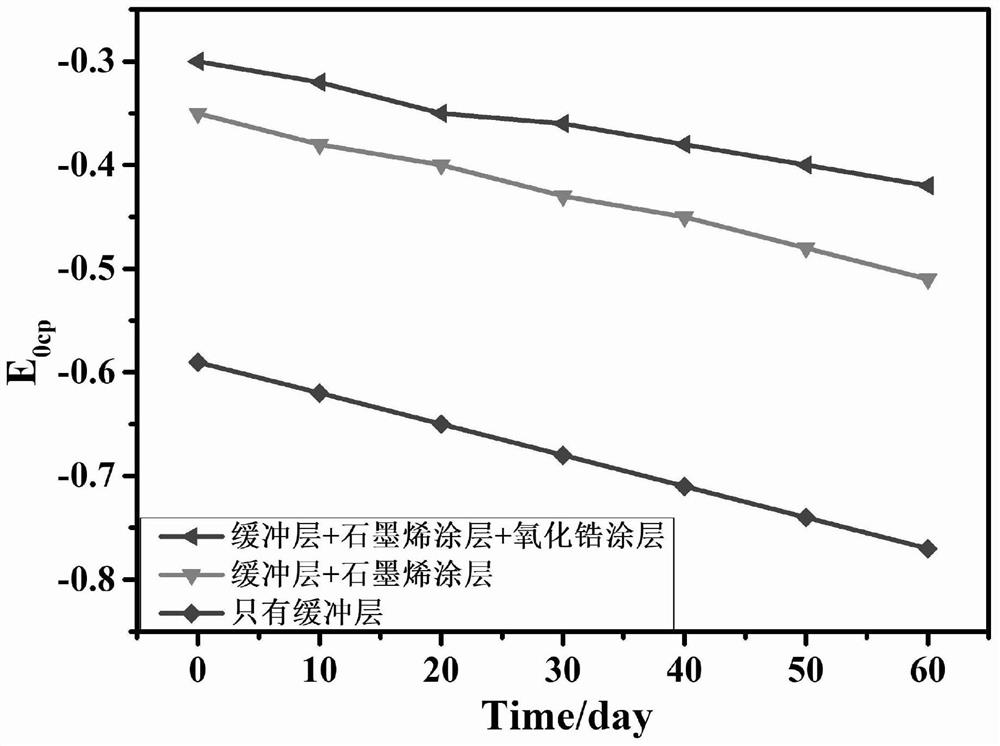

[0070] The preparation method of embodiment 2 is the same as that of embodiment 1, and the difference is that in embodiment 2, no zirconia anti-corrosion layer is coated, and only a buffer layer and a graphene wear-resistant layer are coated on the surface of the aluminum mold body.

[0071] Wherein, the buffer layer has a thickness of 120 μm, the graphene wear-resistant layer has a thickness of 80 μm, and the zirconia anticorrosion layer has a thickness of 170 μm.

Embodiment 3

[0073] The preparation method of embodiment 3 is the same as that of embodiment 1, and the difference is that in the embodiment, the graphene wear-resistant layer and the zirconia anti-corrosion layer are not coated, and only the buffer layer is coated on the surface of the aluminum mold body.

[0074] Carry out anti-corrosion performance contrast test with the aluminum mold of embodiment 1~Example 3, carry out anti-corrosion test in 5wt% Nacl solution, experimental result is as follows figure 1 shown. Experiments have shown that the aluminum mold sample coated with both graphene layer and anti-corrosion layer can effectively inhibit the corrosion of salt solution, and then achieve the purpose of anti-corrosion.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com