Graphene based on lignin in-situ generation and preparation method thereof

An in-situ generation, lignin technology, applied in graphene, chemical instruments and methods, non-metallic elements, etc., to achieve the effects of low cost, high yield and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The invention discloses a preparation method of graphene based on lignin in-situ generation, which comprises the following steps: using lignin as a carbon source, in a vacuum hot-pressing sintering furnace, first performing a high-temperature pyrolysis process, and then performing a cooling process treatment to produce graphene based on lignin in-situ generation; wherein, the high-temperature pyrolysis process includes the first-stage heat treatment and the second-stage heat treatment, specifically including: heating from room temperature to 800 °C at a heating rate of 2-10 °C / min ~1000°C, heat preservation for 30-60min, and gasification and pyrolysis after the first stage of heat treatment to obtain the lignin carbon sphere precursor. Subsequently, the temperature was raised to 1200-1600°C at 2-10°C / min, and held for 5-60min, and the obtained graphene precursor was subjected to a second-stage heat treatment so that the temperature between the lignin carbon spheres was h...

Embodiment 1

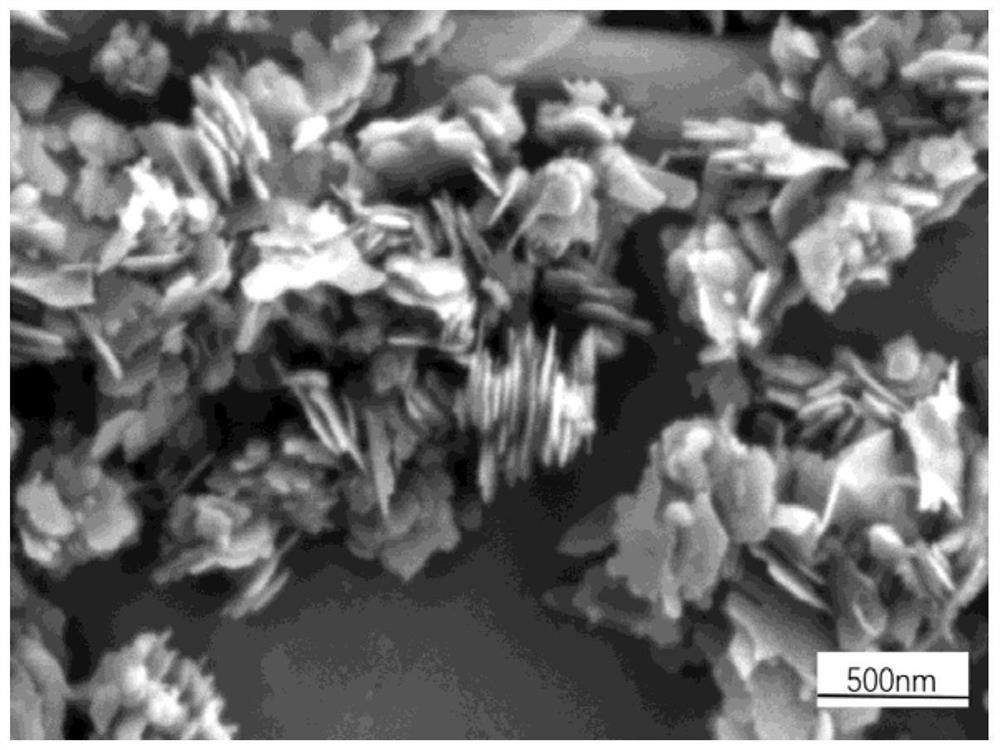

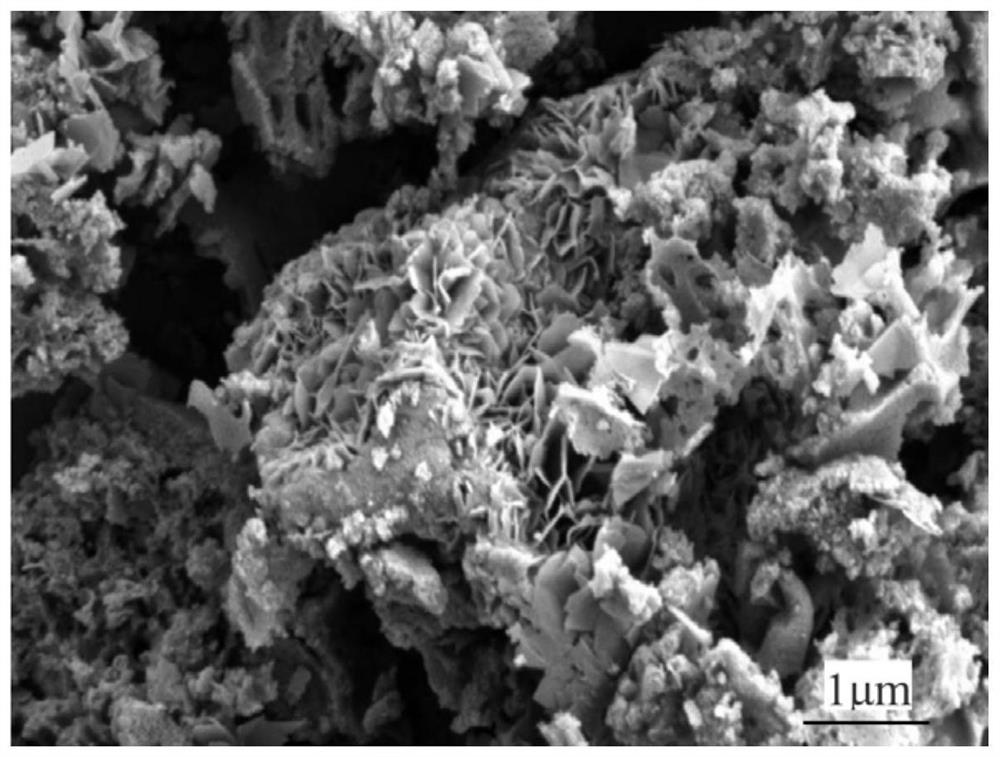

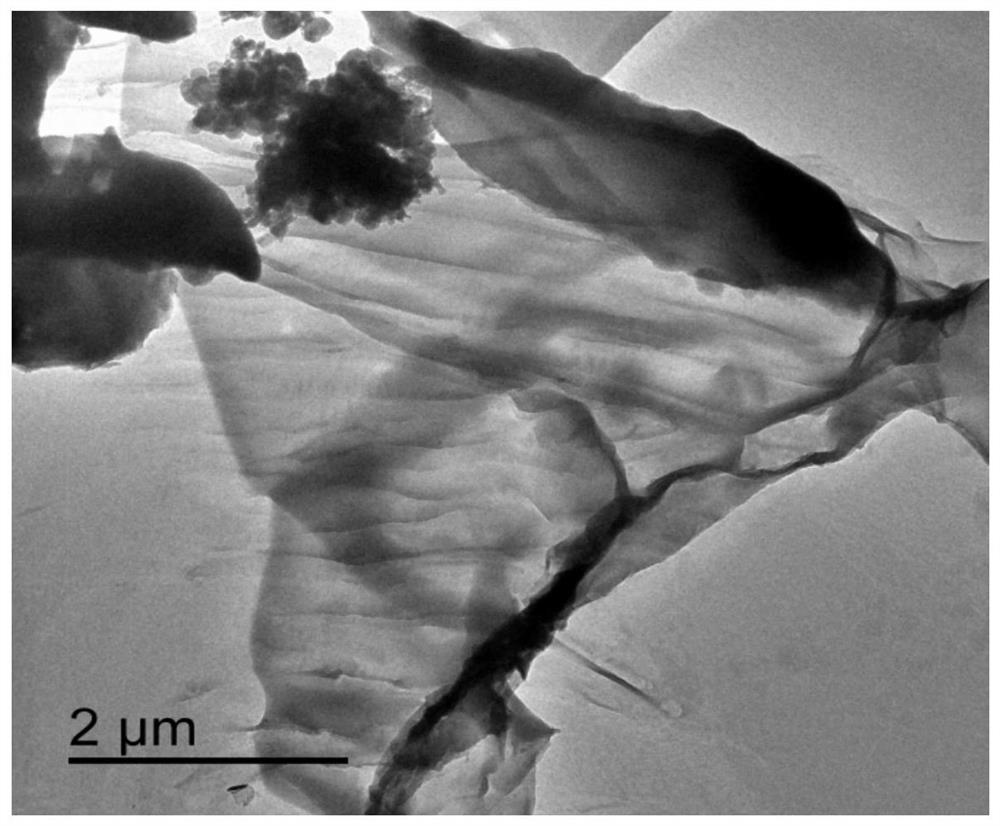

[0047] Put 0.5g of nano-lignin directly in a vacuum hot-pressing sintering furnace for high-temperature pyrolysis: heat up to 800°C at 5°C / min for the first stage of heat treatment, and keep warm for 30 minutes, then continue to heat up to 1200°C at 5°C / min for 30 minutes Carry out the second stage of heat treatment, and then cool down to 400°C at 5°C / min for the cooling process, then cool to room temperature with the furnace and take out graphene powder based on graphene generated in situ from lignin, with a yield of 78% . Adopt scanning electron microscope (SEM) to obtain the sheet thickness of the graphene based on lignin in situ generation of gained is about 12nm, transmission electron microscope (TEM) get the lattice size of the described graphene based on lignin in situ generation is 0.338nm, The sheet thickness is about 13nm. The BET specific surface area test method shows that the obtained graphene based on lignin in situ has a specific surface area of 1050m 2 / g, ...

Embodiment 2

[0049] Put 0.8g of industrial alkali lignin directly in a hot-pressed sintering furnace for high-temperature pyrolysis (at a pressure of 30MPa). After filling nitrogen, heat up to 900°C at 8°C / min for the first-stage heat treatment. After holding for 50min, continue to Raise the temperature to 1300°C at 8°C / min, hold for 30 minutes for the second stage of heat treatment, then cool down to 500°C at 8°C / min for the cooling process, then cool to room temperature with the furnace and take out to obtain graphene based on lignin in situ graphene powder with a yield of 80%. Adopt scanning electron microscope (SEM) to obtain the sheet thickness of the graphene based on the in situ generation of lignin of gained is about 14nm, transmission electron microscope (TEM) obtain the lattice size of the graphene based on the in situ generation of lignin to be 0.401nm, The sheet thickness is about 15nm. The BET specific surface area test method shows that the obtained graphene based on lignin ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com