Environment-friendly marine antifouling coating and preparation method thereof

An environmentally friendly, marine antifouling technology, applied in antifouling/underwater coatings, coatings, paints containing biocides, etc. The effect of preventing biofilm formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

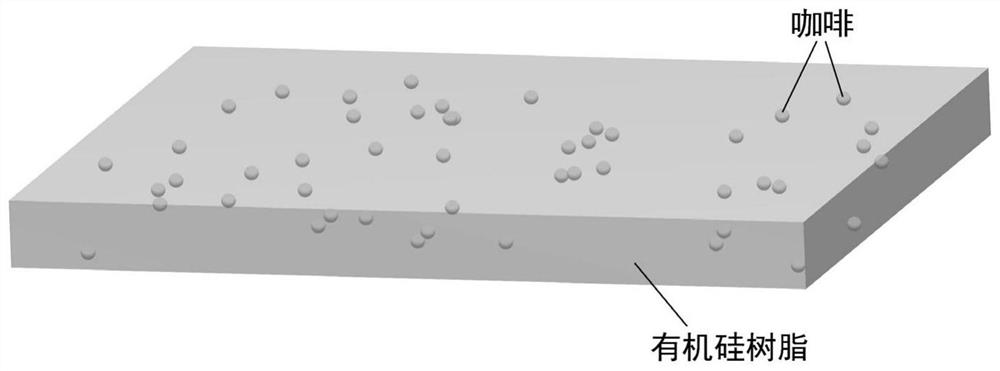

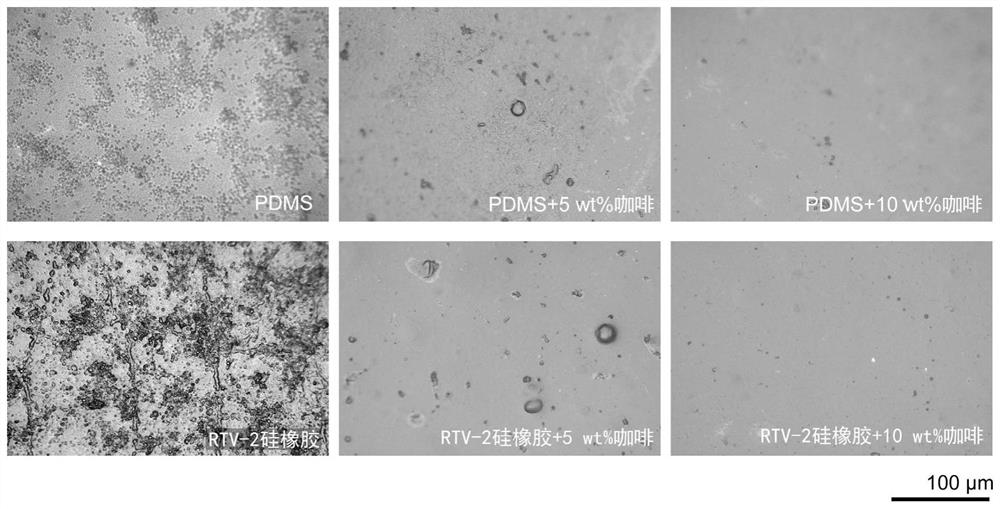

[0019] like figure 1 As shown, in this embodiment, the environment-friendly marine antifouling coating uses silicone resin as a matrix, and coffee particles above 150 mesh are dispersed in the matrix. The silicone resin is a two-component silicone resin. The example is PDMS, and the mass of coffee particles is 4% to 5% of the total mass of the coating.

[0020] (1) Preparation of coffee dispersion

[0021] Grind the pure coffee with a ceramic mortar for 20 minutes, and then screen it with a 150-mesh metal sample sieve to remove large coffee particles. Afterwards, the coffee was dissolved in absolute ethanol (mass ratio 1:4), stirred with a mechanical stirrer for 10 minutes, then placed in an ultrasonic cleaner and vibrated for 30 minutes to obtain a coffee dispersion.

[0022] (2) Preparation of silicone resin dispersion

[0023] Pour component A of the silicone resin into tetrahydrofuran, then keep stirring at a water bath temperature of 55°C, and measure the weight every ...

Embodiment 2

[0027] The difference between this example and Example 1 is that the silicone resin added is RTV-2 silicone rubber, and the mass ratio of AB components is A:B=100:1.5.

Embodiment 3

[0029] The difference between embodiment 3 and embodiment 4 and embodiment 1 is that adding 20 grams of coffee dispersion in step (3) can prepare the environment-friendly marine antifouling coating containing 10wt% coarse coffee.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com