Vegetable oil with oxidized triglyceride polymer removed and removal method

A technology for oxidizing triglycerides and triglycerides, which is applied in food science, edible oil/fat, fat oil/fat refining, etc., can solve the problems of no TGP removal method, achieve a wide range of choices, reduce oil oxidation, Guarantee the effect of product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

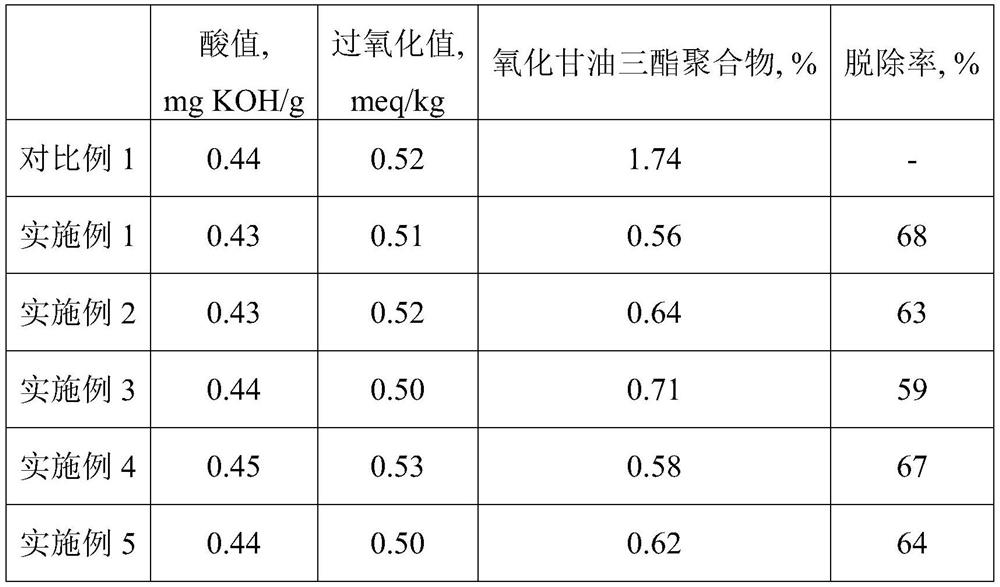

Examples

Embodiment 1

[0039] A method for removing oxidized triglyceride polymers in vegetable oil, said method comprising the steps of:

[0040] ①Change in the arrangement state of polarized molecules: place the deodorized refined perilla seed oil in two parallel plates connected to a 220V power supply, and place the refined perilla seed oil in an electric field environment for 1 hour;

[0041] ② Changes in oil crystallization and rheological behavior: freeze the refined perilla seed oil treated in step ① at -18°C for 0.5h, and stir to promote freezing;

[0042] ③Membrane pretreatment of refined perilla seed oil: use a microporous membrane with a pore size of 0.3 μm in the oil phase for membrane pretreatment;

[0043] ④Gel chromatography column removal:

[0044] a, the grease after the membrane is passed is processed with a gel chromatographic column, with the mobile phase of chloroform and methanol mixed solution with a volume ratio of 1:1, and the flow rate is 30cm / min, and the chromatographic ...

Embodiment 2

[0050] A method for removing oxidized triglyceride polymers in vegetable oil, said method comprising the steps of:

[0051] ①Change in the arrangement state of polarized molecules: place the deodorized refined perilla seed oil in two parallel plates connected to a 120V power supply, and place the refined perilla seed oil in an electric field environment for 0.5h;

[0052] ② Changes in oil crystallization and rheological behavior: freeze the refined perilla seed oil treated in step ① at -20°C for 1 hour, and stir to promote freezing;

[0053] ③Membrane pretreatment of refined perilla seed oil: use a microporous membrane with a pore size of 0.5 μm for the oil phase to perform membrane pretreatment;

[0054] ④Gel chromatography column removal:

[0055] a, the grease after the membrane is passed is processed with a gel chromatographic column, with the mobile phase of chloroform and methanol mixed solution with a volume ratio of 1:1, and the flow rate is 30cm / min, and the chromato...

Embodiment 3

[0061] A method for removing oxidized triglyceride polymers in vegetable oil, said method comprising the steps of:

[0062] ①Change in the arrangement state of polarized molecules: place the deodorized refined perilla seed oil in two parallel plates connected to a 220V power supply, and place the refined perilla seed oil in an electric field environment for 2 hours;

[0063] ②Changes in oil crystallization and rheological behavior: freeze the refined perilla seed oil treated in step ① at -25°C for 0.5h, and stir to promote freezing;

[0064] ③Membrane pretreatment of refined perilla seed oil: use a microporous membrane with a pore size of 0.5 μm for the oil phase to perform membrane pretreatment;

[0065] ④Gel chromatography column removal:

[0066] a, the grease after the membrane is passed is processed with a gel chromatographic column, with the mobile phase of chloroform and methanol mixed solution with a volume ratio of 1:1, and the flow rate is 30cm / min, and the chromato...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com