Preparation method of perovskite quantum dot surface passivation layer suitable for HIT battery

A battery surface and quantum dot technology, applied in the field of solar cells, can solve the problems of HIT battery process incompatibility, etc., and achieve the effects of improving minority carrier life, improving overall efficiency, and enhancing interface electric field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

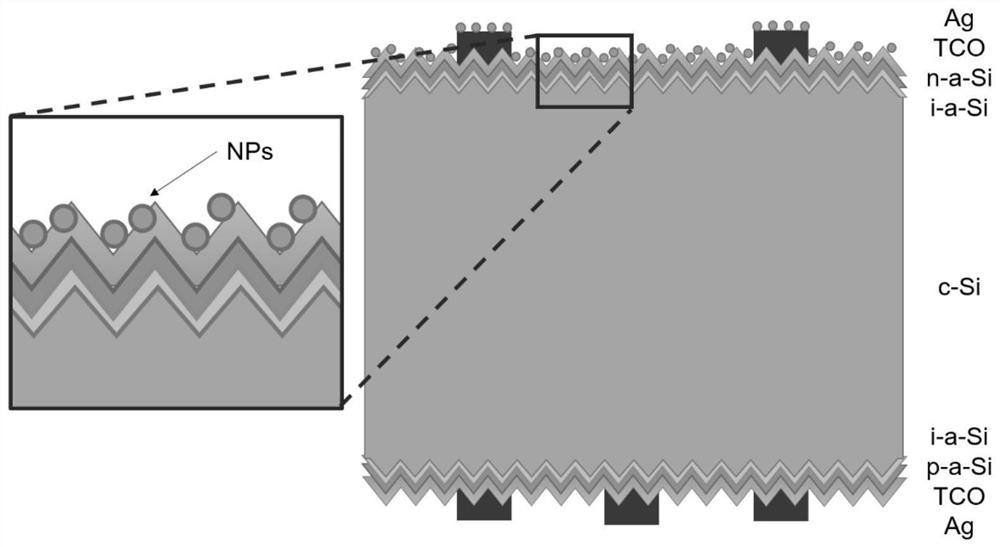

[0027] The preparation method of the surface passivation layer of perovskite quantum dots suitable for HIT battery includes the following steps:

[0028] S1. Provide unencapsulated heterojunction solar cells (Heterojunction with Intrinsic Thin-layer, HIT), and cesium lead bromide perovskite quantum dots dispersed in n-hexane solvent at a concentration of 2 mg / mL. Cesium lead bromide perovskite quantum dots can interact with ITO on the battery surface.

[0029] S2, the cesium lead bromide perovskite quantum dot dispersion liquid is uniformly dispersed on the surface of the heterojunction solar cell, and the cesium lead bromide perovskite quantum dots with a thickness of about 15 nm are deposited. It not only meets the requirements of improving sufficient surface passivation layer, but also does not affect the electrical contact of the battery surface.

[0030] S3. Use a low temperature thermal annealing process at 90°C for 30 minutes to remove excess solvent, so that the cesiu...

Embodiment 2

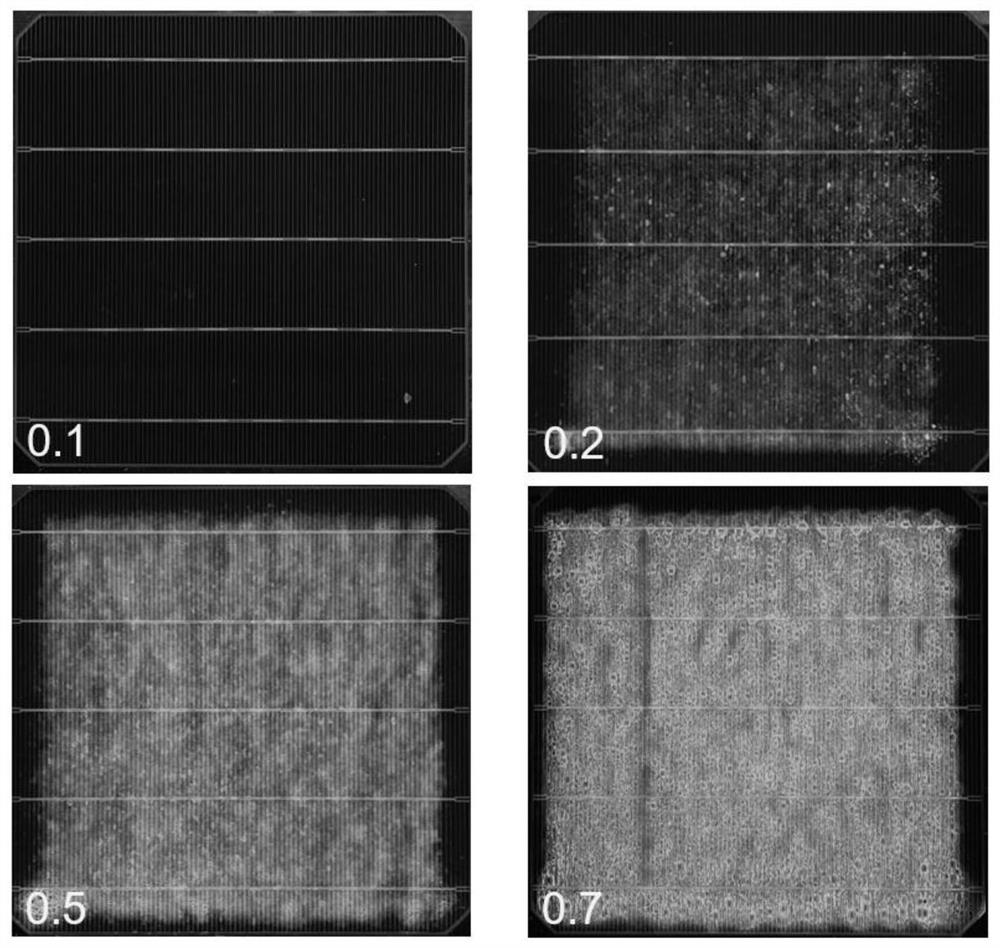

[0033] 1. Device IV characteristic test under different surface quantum dot distribution densities

[0034] The IV data listed in Table 1 were all obtained by the Sinton FCT-450 system test, which was completed in the laboratory of Suzhou Astor Sunshine Power Technology Co., Ltd.

[0035] Comparing the IV performance of heterojunction cells with surface passivation of different amounts of quantum dots, it can be seen that after the surface passivation of perovskite quantum dots, the battery performance can be improved to a certain extent, and the optimal concentration distribution of perovskite quantum dots is in the spray coating. The speed is about 0.2ml / min, and the corresponding quantum dot thickness under this condition is about 15nm.

[0036] Table 1 IV performance parameters of surface passivation heterojunction cells with different surface distribution densities of quantum dots

[0037]

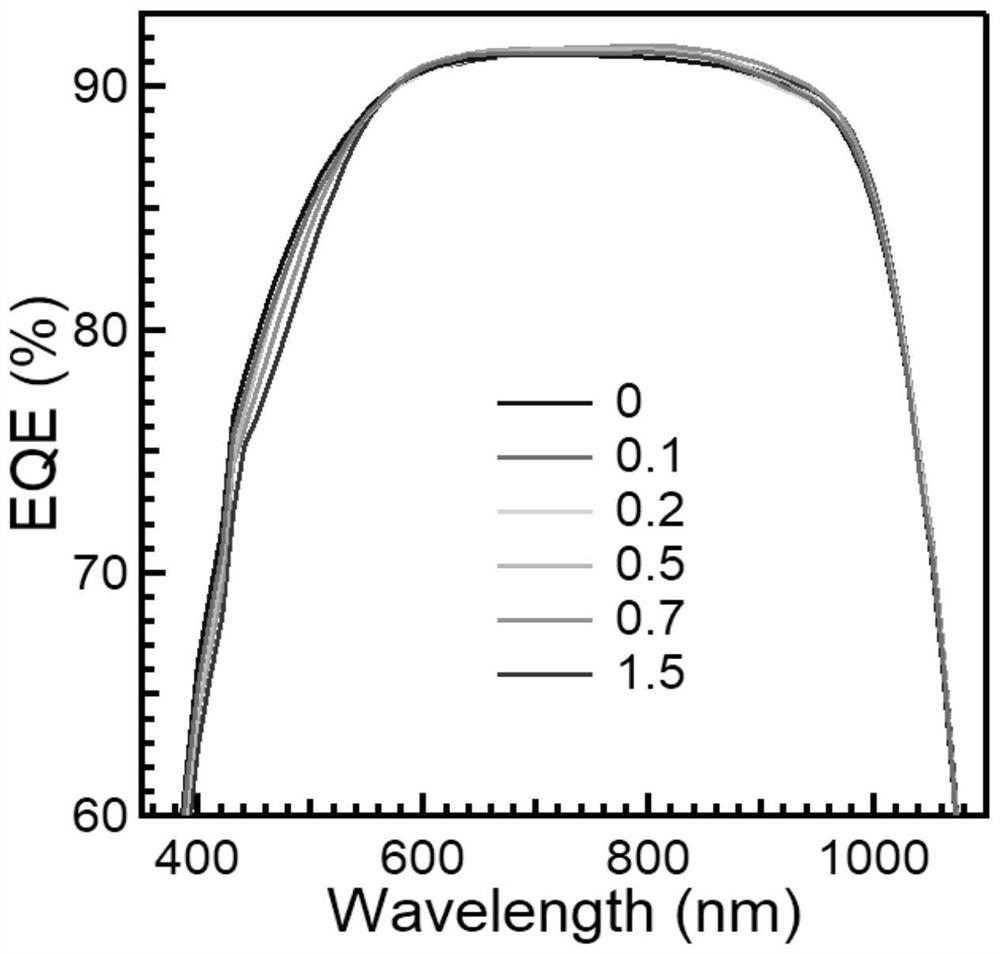

[0038] 2. External quantum efficiency test

[0039] exist image 3 The exte...

Embodiment 3

[0043] 1. Device IV characteristic parameters

[0044]The devices presented in Table 2 were tested with a Newport Solar Simulator and a Keithley 2612 SourceMeter. It can be seen from the comparison that the performance of the solar cell has been improved after the quantum dot modification.

[0045] Table 2 PEDOT with and without quantum dot surface passivation: Comparison of IV characteristic parameters of PSS / Si heterojunction cells

[0046]

[0047] 2. External quantum efficiency test

[0048] exist Figure 4 The external quantum efficiency data of the devices shown in this paper are all obtained through the commercial battery quantum efficiency system test, and the test is completed on the solar cell quantum efficiency instrument of Guangyan Technology Company. The results show that the response is slightly reduced in the short waveband; the quantum dot efficiency is significantly improved in the long waveband, which means that the photocurrent increases.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com