A regenerative vehicle exhaust gas thermoelectric power generation device based on heat pipe-phase change material

A technology for thermoelectric power generation and vehicle exhaust, which is applied to circuit devices, battery circuit devices, electric vehicles, etc., can solve the problems of frequent changes in the temperature of the hot end of the thermoelectric power generation sheet, increasing the difficulty of utilizing the output power, and fatigue damage of the thermoelectric power generation module. To achieve the effect of reducing the impact, improving the power generation efficiency, and alleviating the burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below with reference to the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

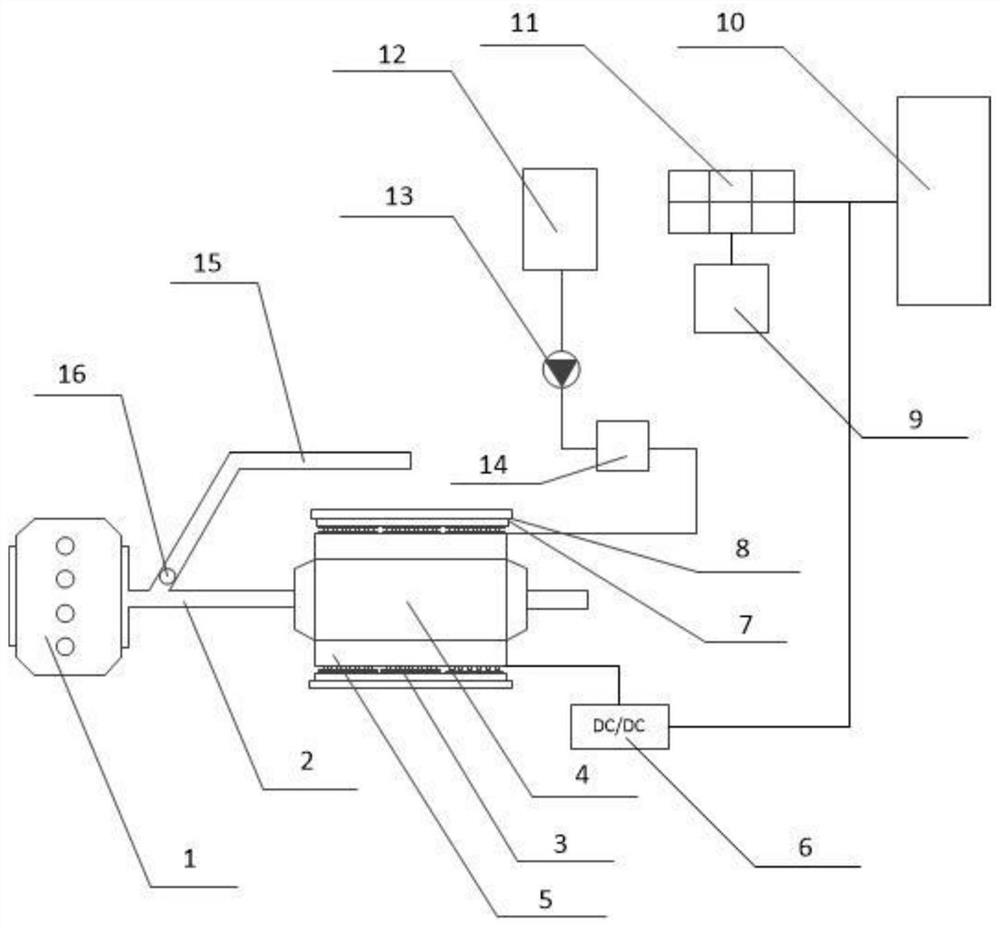

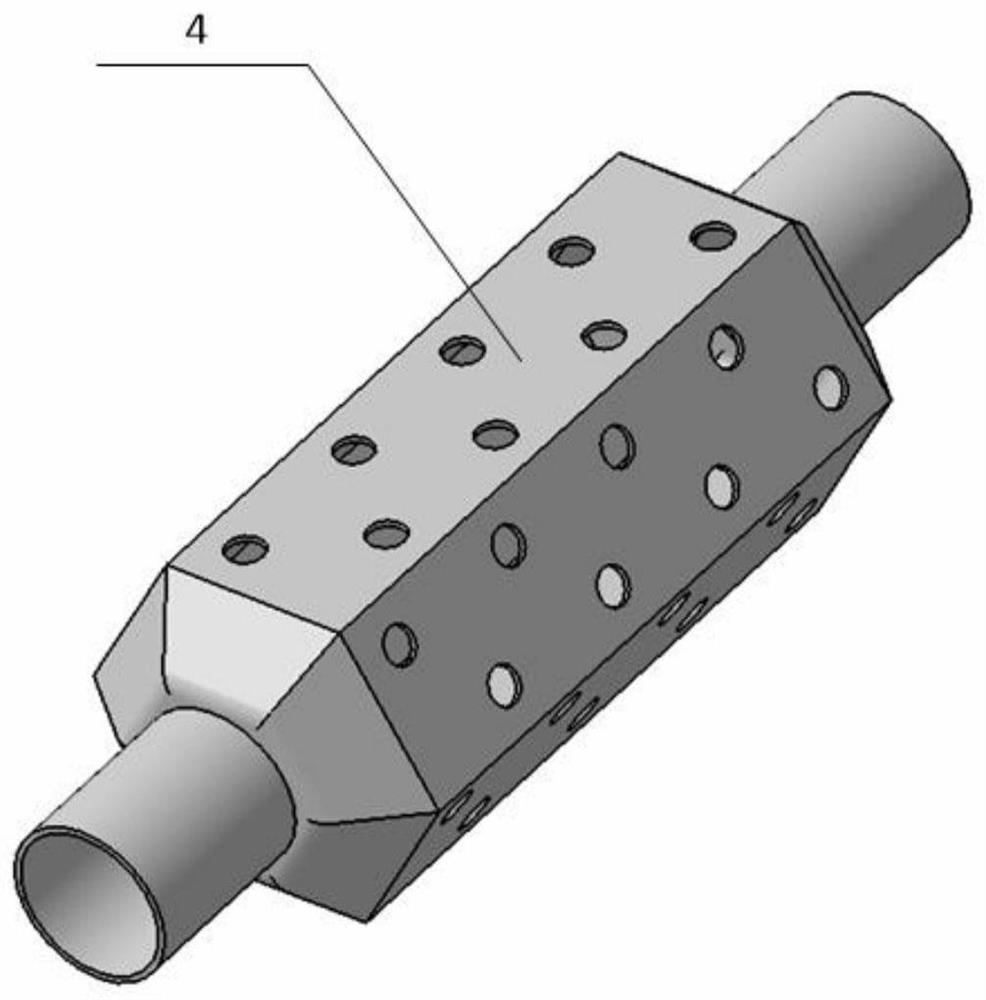

[0032] like figure 1 As shown, the regenerative automobile exhaust thermoelectric power generation device based on the heat pipe-phase change material of the present invention includes an engine 1, an exhaust pipe 2, a thermoelectric power generation sheet 3, a heat collector 4, a phase change energy storage device 5, a DC / DC regulator controller 6, cooling water channel 7, clamping device 8, battery management device 9, electrical load 10, battery pack 11, cooling water tank 12, cooling water pump 13, water temperature controller 14, three-way pipe 15 and Solenoid valve 16.

[0033] The engine 1 is connected to the collector 4 through the exhaust pipe 2, and the engine 1 is also connected to the tee pipe 15 through the exhaust pipe 2. The connection mode of the tee pipe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com