Chlorella, seaweed and sweet potato leaf composite enzyme and preparation method thereof

A composite enzyme and chlorella technology, applied in biochemical equipment and methods, methods based on microorganisms, immobilized on/in organic carriers, etc., can solve the problem of simultaneous solidification of Saccharomyces cerevisiae and Bacillus natto, etc. problem, to achieve the effect of mellow and sweet taste, continuous production, and high nutrient content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The traditional technology adopts the method of adding calcium chloride to sodium alginate solution to prepare glue beads, thereby preparing immobilized bacteria. The inventor found through practice that using this method to immobilize Saccharomyces cerevisiae and Bacillus natto, the curing efficiency is low, and the curing glue The live bacteria content in the pearl is low, and the present embodiment selects sodium alginate to mix with polyvinyl alcohol (group 1), polyacrylamide (group 2), bone collagen (group 3), carrageenan (group 4), agar respectively (Group 5), carrageenan (Group 6), and triacetate fiber (Group 7) composite technical scheme, the dosage mass ratio is 1:1, and the comparison is sodium alginate with a mass fraction of 3%. The preparation method is as follows: firstly prepare seaweed The mixed solution of sodium alginate and the above-mentioned components, the mass fraction of sodium alginate in the solution is 1.5%, the mass fraction of the above-menti...

Embodiment 2

[0038] Embodiment 2 Flavor substance detects

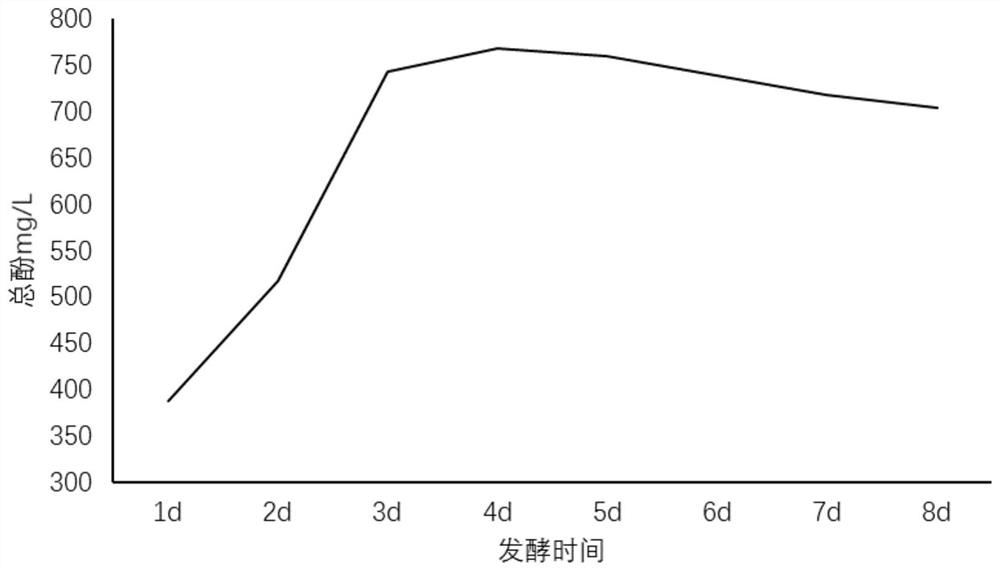

[0039] In this example, Dulse palmatum is used as raw material, Saccharomyces cerevisiae and Bacillus natto are used as fermentation strains, and the flavor substances of fermentation are determined. The fermentation process is as follows: the cleaned Dulse palmatum is crushed until the particle size is less than 5mm Then put the material into the water extraction equipment, add water that accounts for 4 times the weight of the total material weight, the water extraction temperature is 80 ° C, the extraction time is 40 min, filter after extraction, discard the filter residue, and obtain the filtrate; the filtrate is sent to the fermentation tank In the process, add sucrose accounting for 5% of the filtrate mass, insert Saccharomyces cerevisiae and Bacillus natto (prepared in Example 1 group 3, inoculum size 5%), adjust the rotating speed of the fermenter to be 100r / min, and the fermentation temperature is 34°C. Fermentation for 4 ...

Embodiment 3

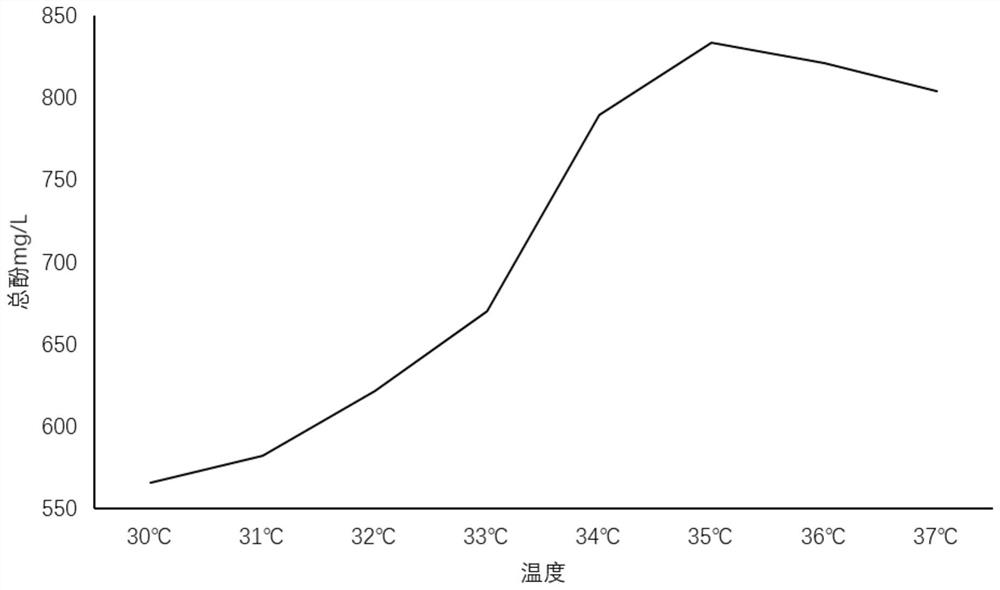

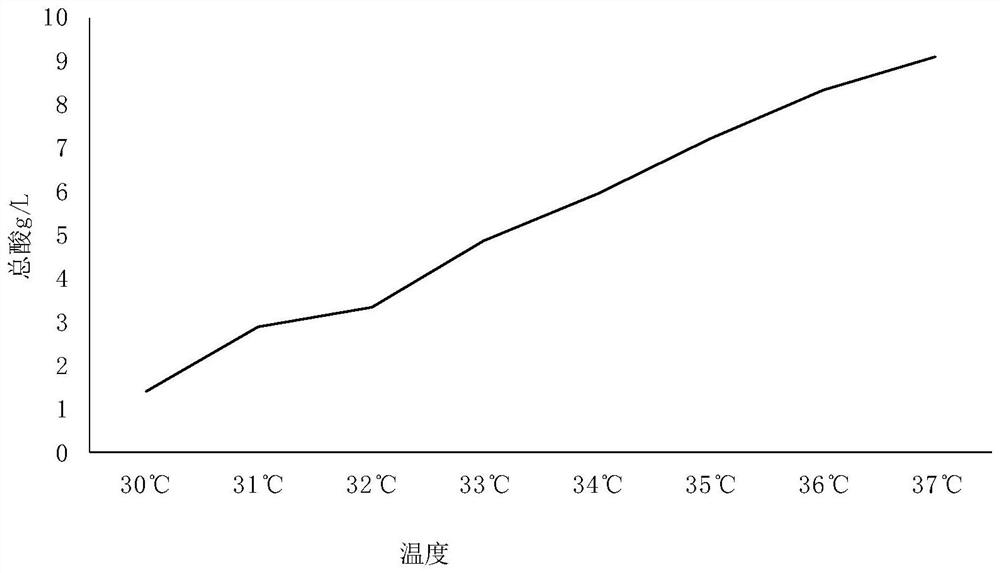

[0048] Embodiment 3 Fermentation material optimization

[0049] In order to increase the content of flavor substances in the fermented product, the inventor selected dulse palmate and seaweed (group 1), kelp (group 2), kelp (group 3), peony cauliflower (group 4), and carrageenan (Group 5) mixed fermentation according to the mass ratio of 2:1, and the control group was fermented with Dulse palmatum alone, and the fermentation process was as follows: the cleaned Dulse palmatum and the above-mentioned seaweed were crushed until the particle size was less than 5mm; Put the material into the water extraction equipment, add water accounting for 4 times the total weight of the material, the water extraction temperature is 80 ° C, the extraction time is 40 minutes, filter after extraction, discard the filter residue, and obtain the filtrate; send the filtrate into the fermentation tank, add The sucrose accounting for 5% of the filtrate quality was inserted into the immobilized bacteri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com