Dry separation process and system for gasification furnace slag

A sorting system and slag technology, applied in chemical instruments and methods, solid waste removal, transportation and packaging, etc., can solve the problem of poor hydrophobicity of unburned carbon, low recovery efficiency, and failure of high-purity recovery of remaining ash components Utilization and other issues, to achieve the effect of strong process adjustability, improve utilization efficiency, and promote coordinated development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

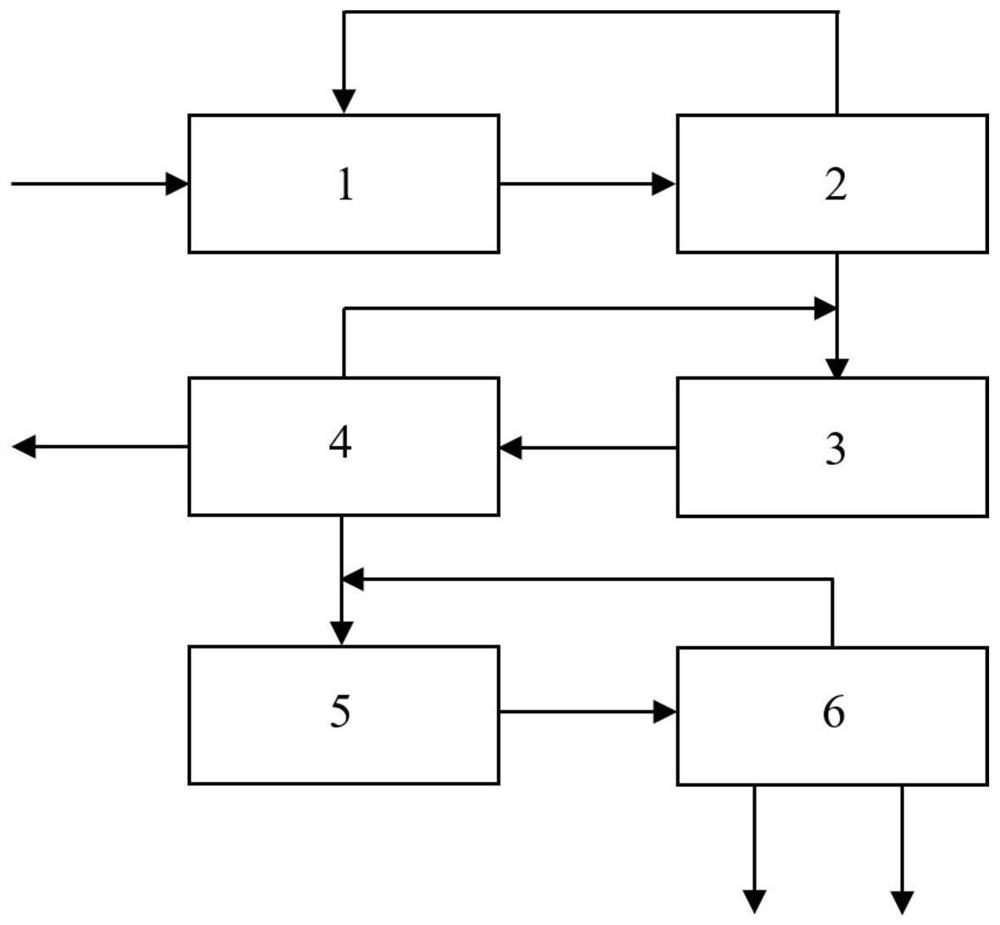

Image

Examples

Embodiment 1

[0029] (1) Pass the gasification slag through a grading sieve with an aperture of 74 μm for particle size classification, the oversize is sent to a ball mill, and the undersize is directly entered into a stage of sorting to separate coarse slag > 74 μm and fine slag ≤ 74 μm;

[0030] (2) Send the coarse-grained slag > 74 μm to a ball mill to grind it below 74 μm;

[0031] (3) Feed the fine-grained slag of ≤74μm into the first-stage sorting system, adopt the friction charging of the electrification chamber, the electrification material is aluminum, adopt the free-falling plate high-voltage electric separation equipment, and set the high-voltage power supply to 40kv to obtain a first-stage separation system. For clean coal, the first-stage tailing coal is sent to the second-stage separation system, and the first-stage medium coal is returned to the electrification device of the first-stage separation to form a circular separation;

[0032] (4) Send a section of tailings coal to ...

Embodiment 2

[0035] (1) Pass the gasification slag through a grading sieve with an aperture of 74 μm for particle size classification, the oversize is sent to a ball mill, and the undersize is directly entered into a stage of sorting to separate coarse slag > 74 μm and fine slag ≤ 74 μm;

[0036] (2) Send the coarse-grained slag > 74 μm to a ball mill to grind it below 74 μm;

[0037] (3) Difference with embodiment 1, the electrification equipment of one section sorting adopts electrification chamber to add friction bar friction electrification, and electrification material is stainless steel, and separation equipment adopts strip separation type, and high-voltage power supply is set to 50kv, obtains a section Clean coal, the tailings of the first stage are sent to the second stage separation system;

[0038] (4) difference with embodiment 1, the electrification equipment of two-stage sorting adopts swirl type friction electrification, and electrification material is copper, and separation e...

Embodiment 3

[0041] (1) Pass the gasification slag through a grading sieve with an aperture of 74 μm for particle size classification, the oversize is sent to a ball mill, and the undersize is directly entered into a stage of sorting to separate coarse slag > 74 μm and fine slag ≤ 74 μm;

[0042] (2) Send the coarse-grained slag > 74 μm to a ball mill to grind it below 74 μm;

[0043] (3) The difference with embodiment 1 is that the electrification equipment of one section of sorting adopts insulating belt corona electrification, the separation equipment adopts strip-shaped separation type, and the high voltage power supply is set to 45kv to obtain one section of clean coal, and one section of tailing coal is sent to the second section sorting system;

[0044] (4) difference with embodiment 1, the electrification equipment of two stage sorting adopts swirling flow type friction electrification, and electrification material is stainless steel, and separation equipment adopts strip separatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com