3D printing device and method for integrated manufacturing of continuous functionally graded materials and structures

A functionally graded material, 3D printing technology, applied in coating devices, manufacturing tools, additive manufacturing, etc., to achieve the effects of high precision, high stability and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

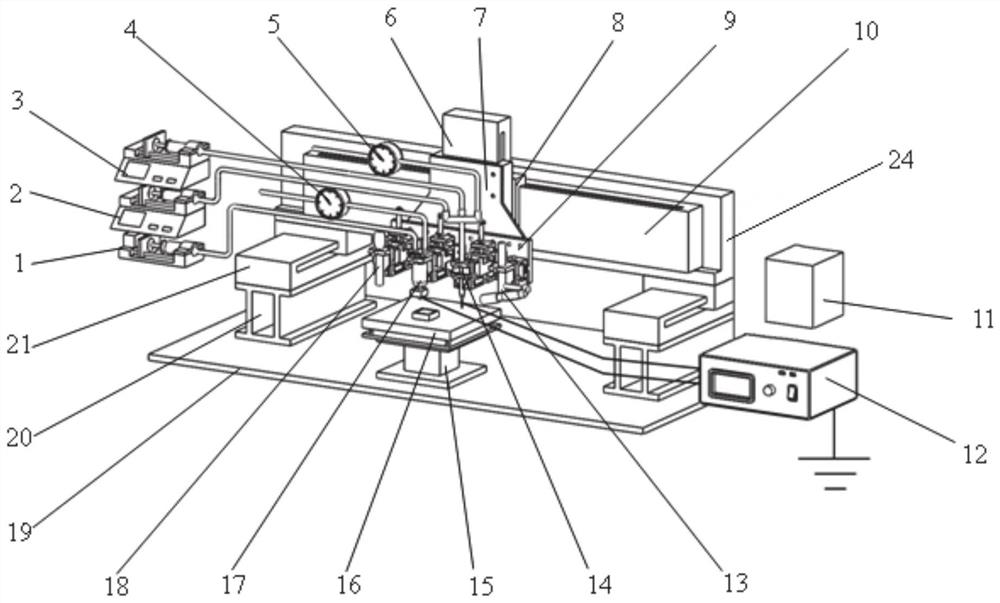

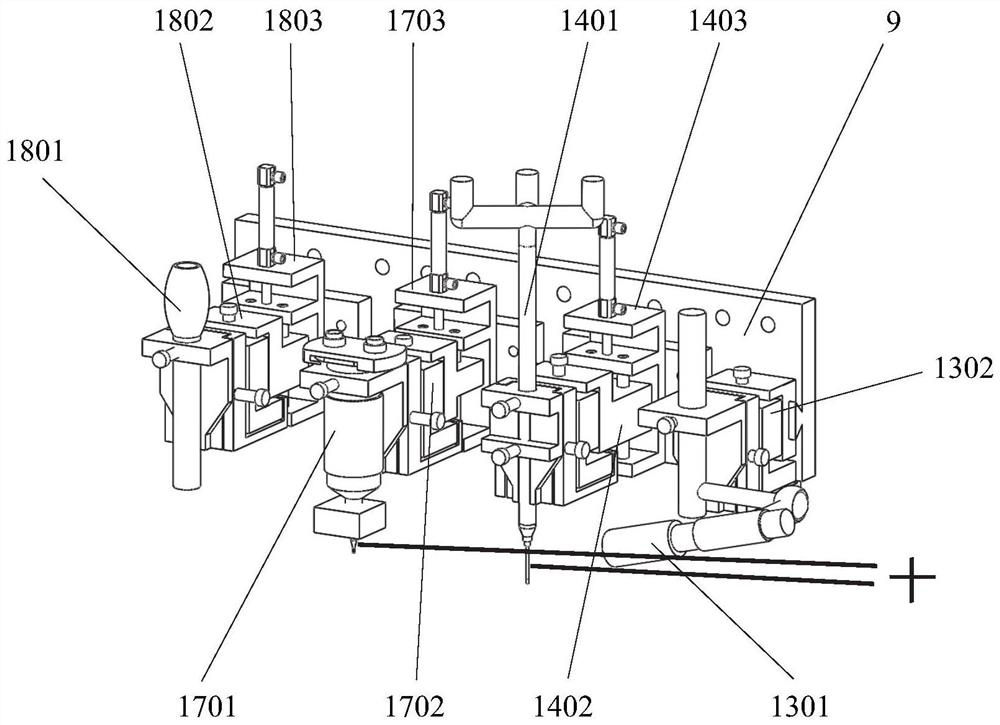

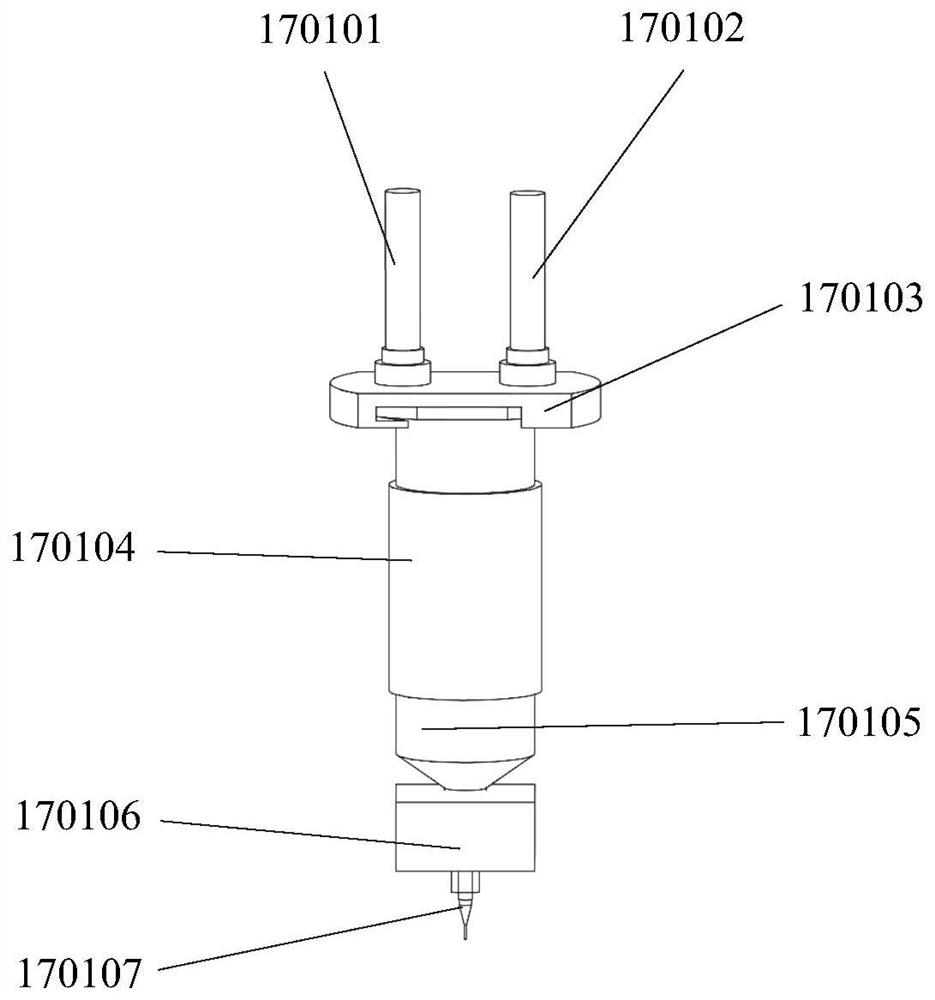

[0081] This embodiment provides a 3D printing device integrated with continuous functionally graded materials and structures, such as figure 1 As shown, it includes constraint sacrificial layer feeding module 1, passive mixing feeding module I2, passive mixing feeding module II3, air pressure regulating valve table I4, air pressure regulating valve table II5, X-axis motion module 10, Y-axis motion module 21. Z-axis motion module 6, connecting frame VII7, connecting frame I8, connecting frame II9, positive pressure gas circuit 11, high voltage DC power supply 12, auxiliary observation camera module 13, passive hybrid printing module 14, printing platform base 15, printing platform 16. Constraining the sacrificial layer printing module 17, UV curing module 18, base plate 19, bracket I20, bracket II24;

[0082] The Y-axis motion modules 21 are fixed above the bottom plate 19 through the bracket I20. In this embodiment, two Y-axis motion modules 21 are provided, and the two Y-axis...

Embodiment 2

[0107] This embodiment provides a 3D printing method for the integrated manufacture of continuous functionally graded materials and structures, using the printing device described in Embodiment 1, such as Figure 8 shown, including the following steps:

[0108] (1) Model settings. Determine the geometry of the printed part;

[0109] (2) Model information processing. Determine the geometric information of each layer (path, layer thickness, etc.), and generate a print data file;

[0110] (2) Pre-print processing, complete the preparatory work before printing. Determine the material ratio, preprocess printing material I and printing material II respectively; set the printing feeding speed, printing speed, bottom plate temperature, nozzle temperature, air pressure, voltage, etc.;

[0111] (3) Printing the functionally graded structure, mainly including the passive hybrid printing nozzle 1401 and the constrained sacrificial layer printing nozzle 1701 cooperating with each other...

Embodiment 3

[0136] This embodiment provides a 3D printing device integrated with continuous functionally graded materials and structures, such as Figure 5 As shown, it includes constraint sacrificial layer feeding module 1, passive mixing feeding module I2, passive mixing feeding module II3, air pressure regulating valve table II5, X-axis movement module 10, Y-axis movement module 21, Z-axis movement module Group 6, positive pressure air circuit 11, high voltage DC power supply 12, auxiliary observation camera module 13, passive hybrid printing module 14, printing platform base 15, printing platform 16, FDM wire feeding module 22, FDM printing module 23, UV curing module 18, Bottom plate 19; wherein, the installation methods of the X-axis motion module 10, the Y-axis motion module 21, the Z-axis motion module 6, and the printing platform 16 are the same as those in the first embodiment, and will not be repeated here.

[0137] Further, in this embodiment, a printing material I is placed i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com