A kind of extraction method of Radix Polygoni Multiflori polysaccharide

An extraction method and the technology of Baishouwu polysaccharides, which are applied in the field of polysaccharide extraction of Baishouwu, can solve the problems of less extraction, low product grades, unsalable products, etc., and achieve the goal of increasing the yield of polysaccharides, improving the industrial structure, and shortening the process cycle Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A method for extracting polysaccharides from Polygonum multiflorum, specifically implemented according to the following steps:

[0030] (1) Pretreatment of Radix Polygoni Multiflori: Take 100 g of Radix Radix Polygoni Multiflori root after washing, cut into pieces and put into a pulverizer, grind into powder and pass through an 80-mesh sieve;

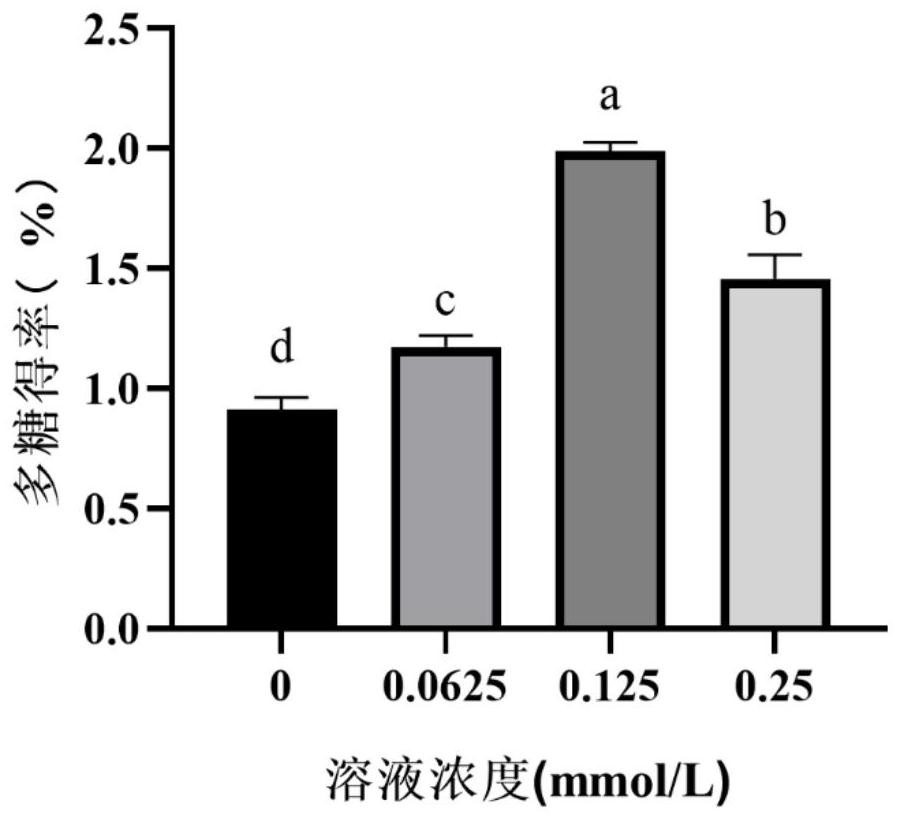

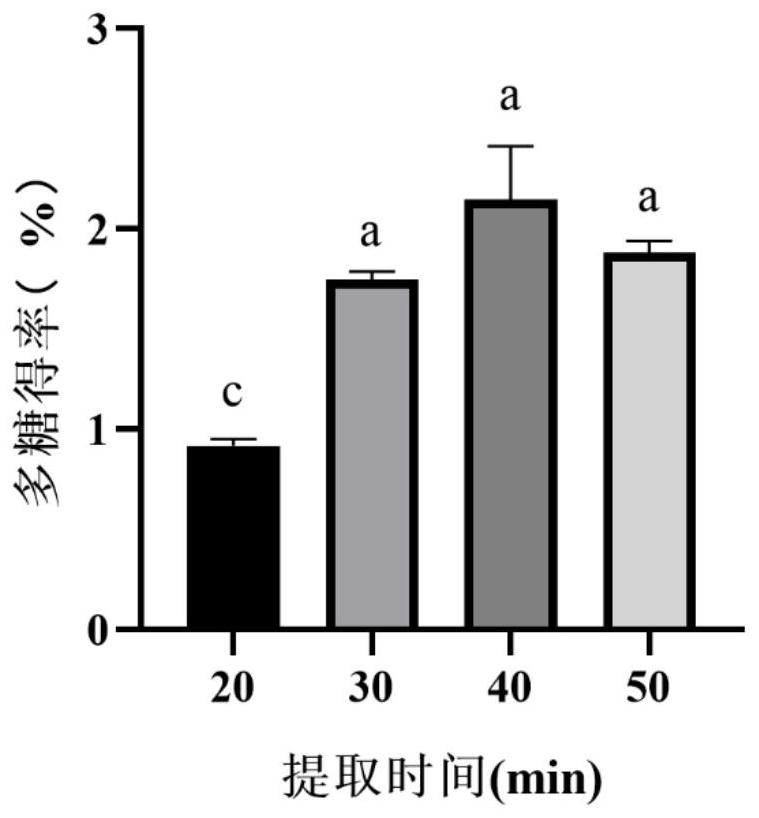

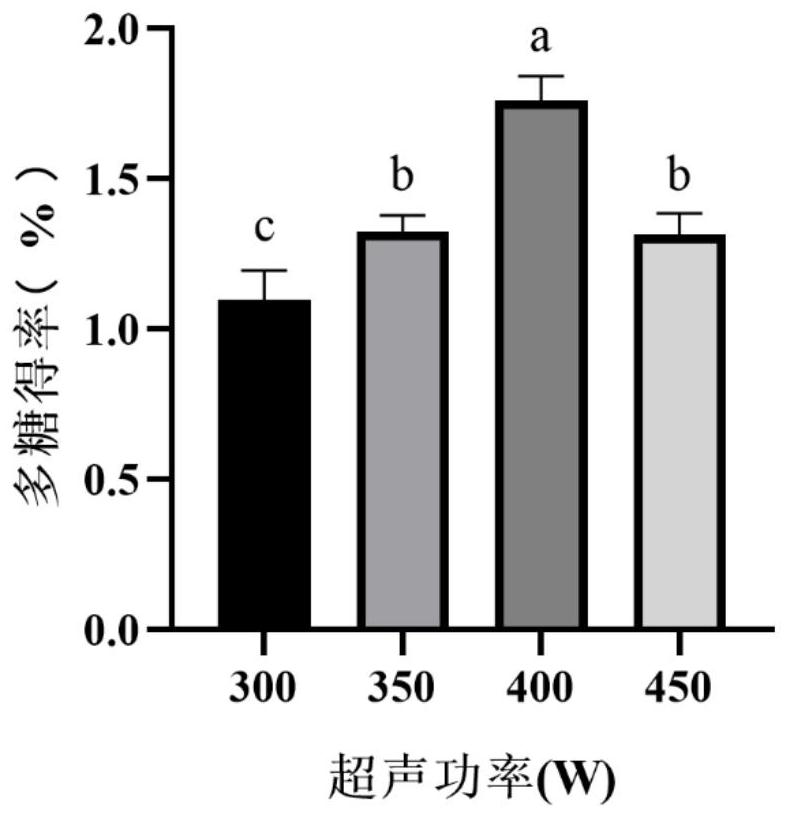

[0031] (2) Extraction of polysaccharides of Radix Polygoni Multiflori: Dissolve 100g of Radix Polygoni Multiflori powder in 0.125mmol / L alkyl glycoside solution, place it in a circulating ultrasonic extraction machine, and extract according to the extraction time of 30min, ultrasonic power of 400W, and extraction temperature of 50°C. Conditions for extraction, after the extraction, pour the extract into a centrifuge cup, and centrifuge at a speed of 4000r / min for 10min.

[0032] (3) Precipitation and separation of polysaccharides from Radix Polygoni Multiflori: Transfer the supernatant to a rotary evaporator, evaporate to 1 / 4 vol...

Embodiment 2

[0034] A method for extracting polysaccharides from Polygonum multiflorum, specifically implemented according to the following steps:

[0035] (1) Pretreatment of Radix Polygoni Multiflori: Take 100 g of Radix Radix Polygoni Multiflori root after washing, cut into pieces and put into a pulverizer, grind into powder and pass through an 80-mesh sieve;

[0036] (2) Extraction of polysaccharides of Radix Polygoni Multiflori: Dissolve 100g of Radix Polygoni Multiflori powder in 0.0625mmol / L alkyl glycoside solution, place it in a circulating ultrasonic extraction machine, and extract according to the extraction time of 30min, ultrasonic power of 400W, and extraction temperature of 50°C. Conditions for extraction, after the extraction, pour the extract into a centrifuge cup, and centrifuge at a speed of 4000r / min for 10min.

[0037] (3) Precipitation and separation of polysaccharides from Radix Polygoni Multiflori: Transfer the supernatant to a rotary evaporator, evaporate to 1 / 4 vo...

Embodiment 3

[0039] A method for extracting polysaccharides from Polygonum multiflorum, specifically implemented according to the following steps:

[0040] (1) Pretreatment of Radix Polygoni Multiflori: Take 100 g of Radix Radix Polygoni Multiflori root after washing, cut into pieces and put into a pulverizer, grind into powder and pass through an 80-mesh sieve;

[0041] (2) Extraction of Baishouwu polysaccharide: 100g of Baishouwu powder was dissolved in 0.25mmol / L alkyl glycoside solution, placed in a circulating ultrasonic extraction machine, according to the extraction time of 30min, ultrasonic power of 400W, and extraction temperature of 50°C Conditions for extraction, after the extraction, pour the extract into a centrifuge cup, and centrifuge at a speed of 4000r / min for 10min.

[0042](3) Precipitation and separation of polysaccharides from Radix Polygoni Multiflori: Transfer the supernatant to a rotary evaporator, evaporate to 1 / 4 volume, then use the Sevag method to remove protein...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com