Pressure difference control method and control device for air pre-heaters of coal-fired power plant

A technology for a coal-fired power plant and a control method, applied in the combustion method, control combustion, exhaust gas device and other directions, can solve the problems of rising fan running current, high outlet pressure of the blower, affecting running economy, etc. Reduce the outlet pressure, the effect of soot blowing is remarkable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

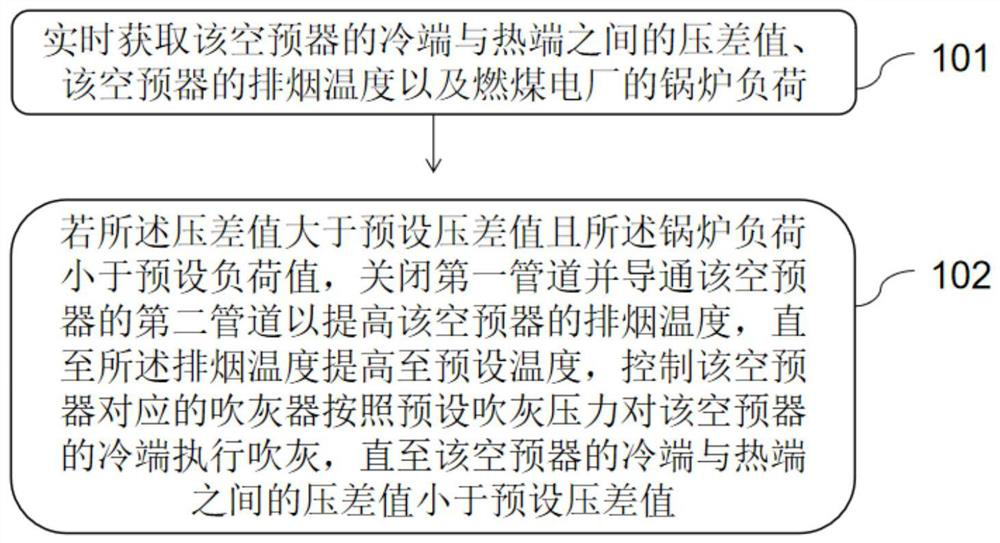

Method used

Image

Examples

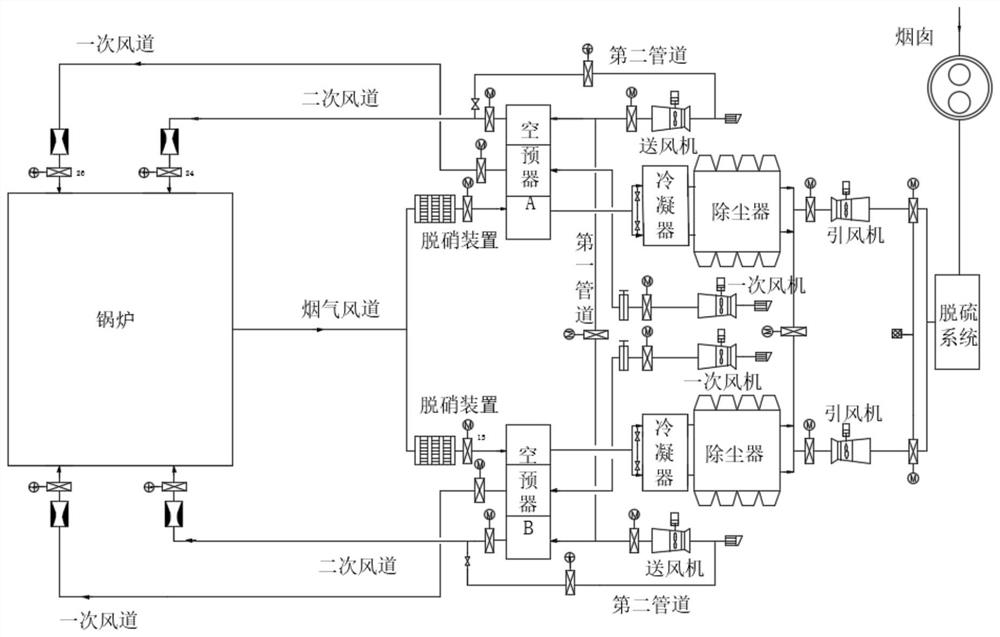

Embodiment 1

[0068]In this example, taking the 4*660MW unit of Zheneng Lanxi Power Plant as an example, the boiler adopts the B&W B-1903 / 25.4-M supercritical parameter variable pressure once-through boiler of Bawei Boiler Factory, and is a single furnace, once reheated, Balanced ventilation, open-air layout, solid slag discharge, all-steel frame plus light metal roof, fully suspended structure Π-type boiler; the boiler is equipped with two three-chamber rotary air preheaters, named air preheater A and air preheater respectively. The model of air preheater B is 31.5VNT 1850. The main radial partition extending from the central cylinder divides the rotor into 24 compartments, and each sub-compartment is divided into 48 compartments by secondary radial partitions. There are three types of airflow through the air preheater, namely flue gas, secondary air and primary air; the diameter of the rotor is 14080mm, the height of the heat exchange element is 1850mm, and the rotor compartment is equippe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com