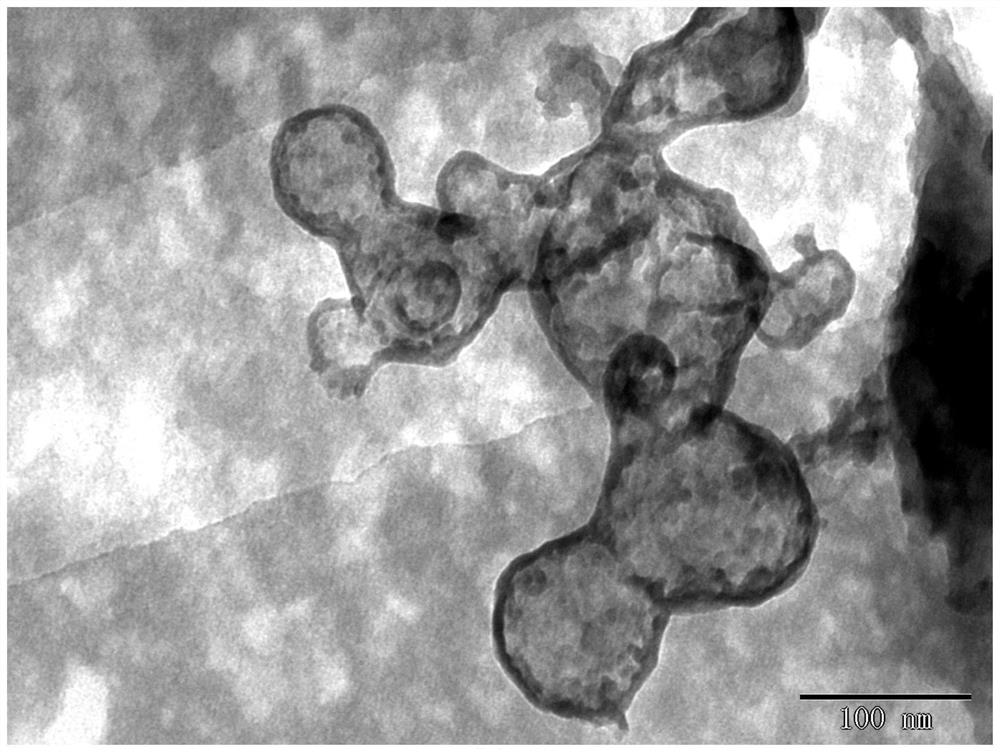

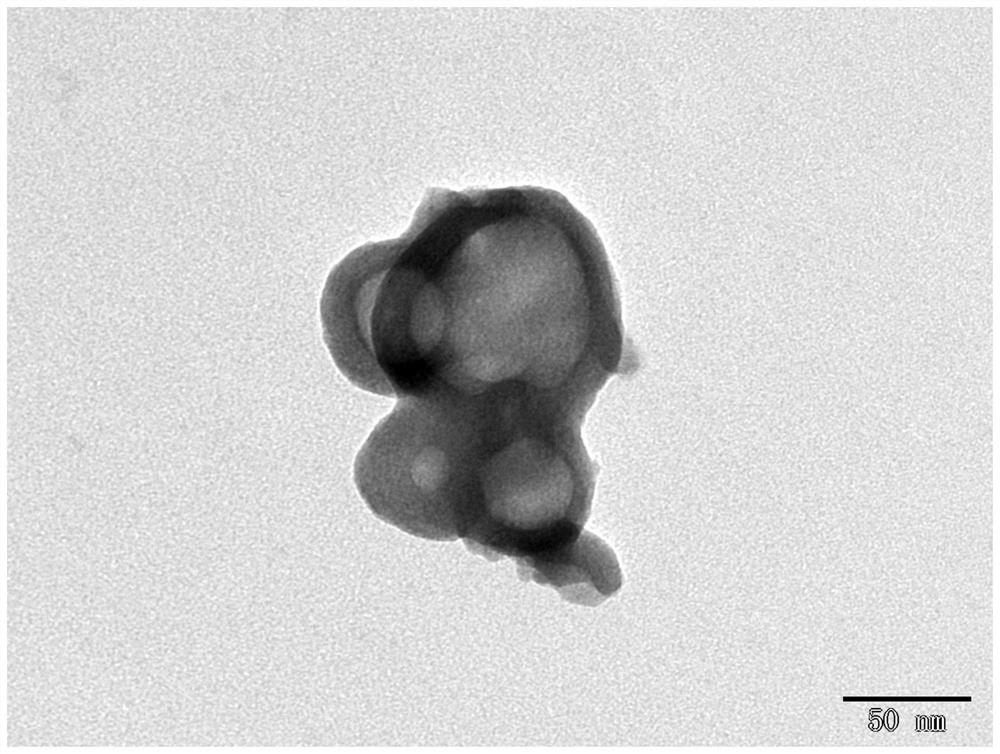

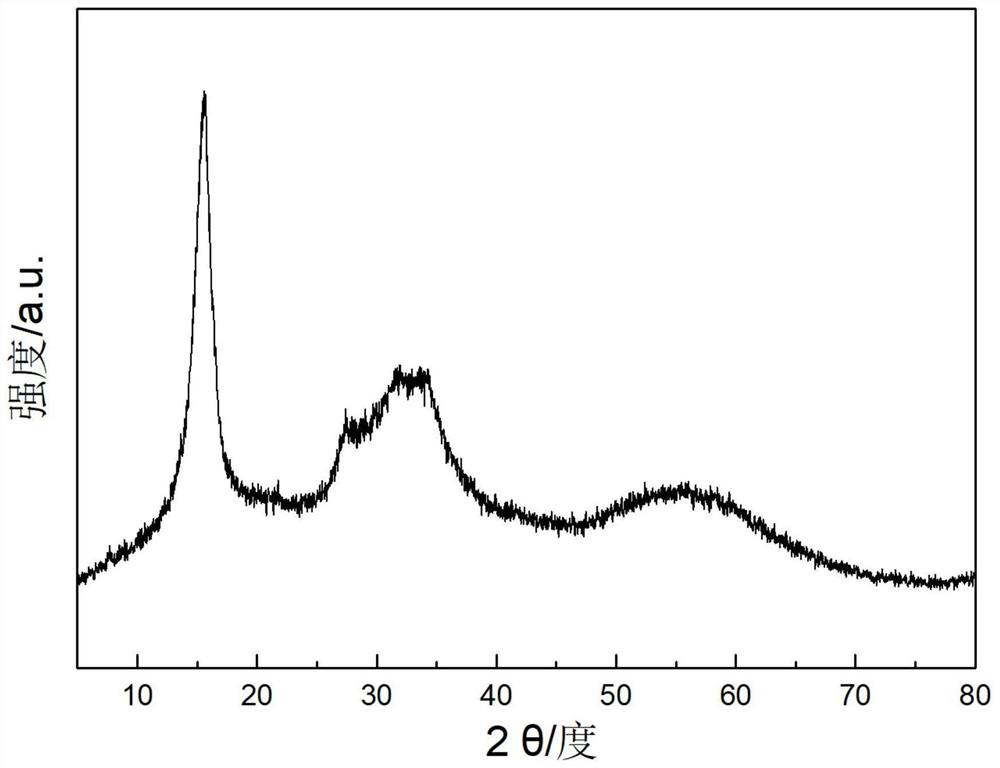

A kind of controllable preparation method of nanometer red phosphorus hollow sphere

A hollow sphere, red phosphorus technology, applied in nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve the problems of unsuitability for the production of red phosphorus-based nanomaterials, high toxicity, etc., to reduce the difficulty of industrialization, and to easily obtain raw materials , the effect of cheap raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Step 1. Weigh 0.02g-0.06g of red phosphorus, then transfer it to an empty agate mortar, grind it with a pestle for 5-20 minutes, and then sieve with a 200-mesh sieve to obtain 200-mesh red phosphorus powder.

[0030] Step 2, transfer the red phosphorus powder obtained above to a quartz tube with a diameter of 15 mm through necking treatment, vacuumize, and then pass in nitrogen protective gas.

[0031] Step 3: Repeat the content of step 2 for 3 to 4 times to finally obtain red phosphorus powder under negative pressure and nitrogen atmosphere.

[0032] Step 4. Preheat the above-mentioned quartz tube containing red phosphorus powder with a flame gun, and then direct the flame at the constriction of the quartz tube and heat for 2 minutes to obtain a completely sealed quartz tube under a vacuum state and a nitrogen atmosphere.

[0033] Step 5, placing the above-mentioned quartz tube in the middle of the tube furnace. Raise the temperature at 5°C / min to 300-500°C, keep it w...

Embodiment 2

[0038] Step 1. Weigh 0.1g-0.4g of red phosphorus, then transfer it to an empty agate mortar, grind with a pestle for 5-20 minutes, and then sieve with a 200-mesh sieve to obtain 200-mesh red phosphorus powder.

[0039] Step 2, transfer the red phosphorus powder obtained above to a quartz tube with a diameter of 15 mm through necking treatment, vacuumize, and then pass in nitrogen protective gas.

[0040] Step 3: Repeat the content of step 2 for 3 to 4 times to finally obtain red phosphorus powder under negative pressure and nitrogen atmosphere.

[0041] Step 4. Preheat the above-mentioned quartz tube containing red phosphorus powder with a flame gun, and then direct the flame at the constriction of the quartz tube and heat for 2 minutes to obtain a completely sealed quartz tube under a vacuum state and a nitrogen atmosphere.

[0042] Step 5, placing the above-mentioned quartz tube in the middle of the tube furnace. Raise the temperature at 5°C / min to 500-800°C, keep it warm f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com