High-melt-strength biodegradable polyester material and preparation method thereof

A biodegradable polyester, high melt strength technology, applied in biological packaging, sustainable manufacturing/processing, sustainable packaging, etc. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

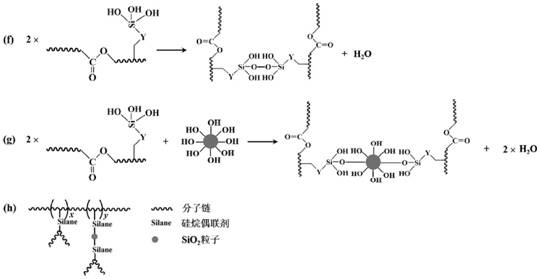

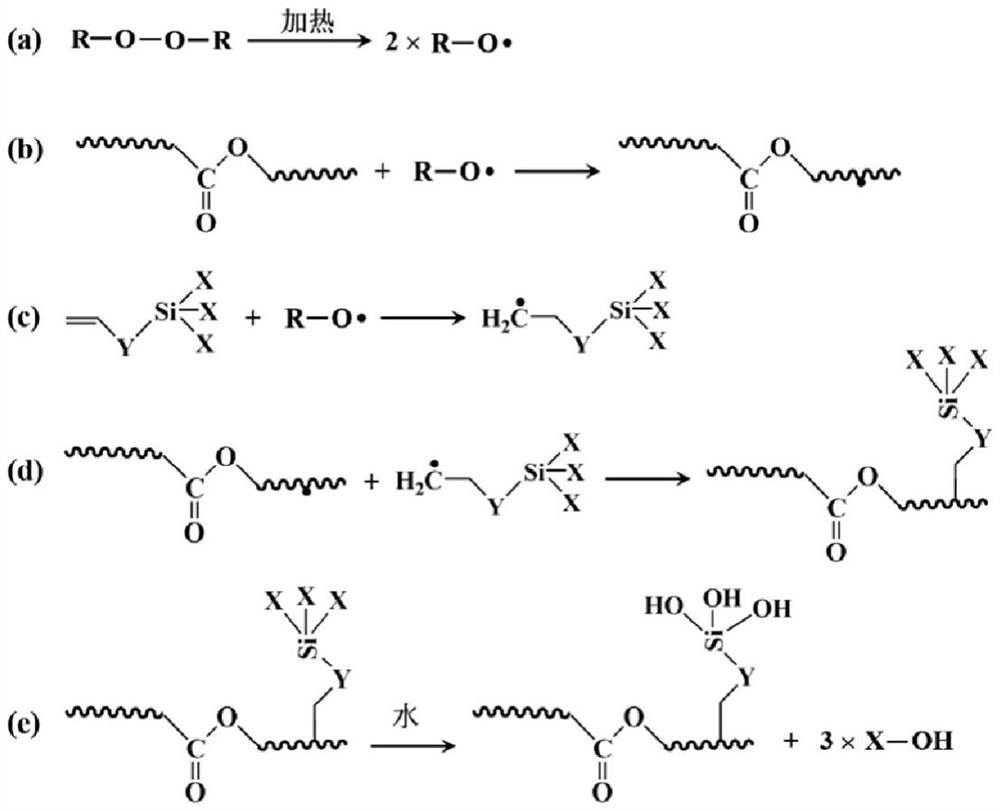

Method used

Image

Examples

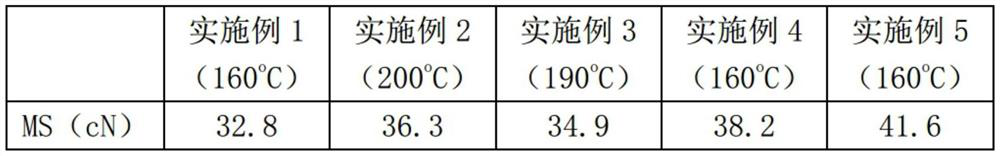

Embodiment 1

[0046] In this embodiment, the preparation method of such a high melt strength bio-derived polyester material sequentially includes the following steps:

[0047] (1) According to the weight, it is equipped with the following raw materials: biodegradable polyester 98.05% (polybut dikalate), organic peroxide 0.15% (tert-butyl peroxide-2-ethylhexate) 0.80% (vinyl triethoxysilane), silica particles (nano silica particles);

[0048] (2) The biodegradable polyester was dried at 90 ° C for 90 min, so that the moisture content of the biodegradable polyester was less than 200 ppm and cooled to 25 ° C;

[0049] (3) The organic peroxide and 0.40% silane coupling agent were added to the biodegradable polyester and mixed uniform to obtain a mixture;

[0050] (4) The silica particles were dried at 110 ° C for 120 min, so that the moisture content of the silica particles was less than 200 ppm, and cooled to 30 ° C;

[0051] (5) Spray the remaining 0.4% silane coupling agent on the surface of the...

Embodiment 2

[0058] In this embodiment, the preparation method of such a high melt strength bio-derived polyester material sequentially includes the following steps:

[0059] (1) According to the weight, it is equipped with the following raw materials: biodegradable polyester 98.80% (polylactic acid), organic peroxide 0.20% (tert-butyl peroxide), 0.50% silane coupling agent (γ- Methyl acryloyloxypropyl trimethoxysilane), 0.50% of silica particles (nano-stage silica particles);

[0060] (2) The biodegradable polyester was dried at 100 ° C for 120 min, so that the moisture content of the biodegradable polyester was less than 200 ppm and cooled to 20 ° C;

[0061] (3) The organic peroxide and 0.30% silane coupling agent are added to the biodegradable polyester and mix well to obtain a mixture;

[0062] (4) The silica particles were dried at 120 ° C for 100 min, so that the moisture content of the silica particles was less than 200 ppm, and cooled to 20 ° C;

[0063] (5) Spray the remaining 0.2% s...

Embodiment 3

[0070] In this embodiment, the preparation method of such a high melt strength bio-derived polyester material sequentially includes the following steps:

[0071] (1) According to the weight, it is equipped with the following raw materials: biodegradable polyester 98.60% (poly (3-hydroxybutyrate-CO-3-hydroxyvalectate), organic peroxide 0.30% (tertomylene) Oxidation-2-ethylhexyl carbonate), silane coupling agent 0.60% (gamma-methylproxyloxylpropyl trimethoxysilane), silica particles 0.50% (nano-grade silica particles);

[0072] (2) The biodegradable polyester was dried at 95 ° C for 80 min, so that the moisture content of the biodegradable polyester was less than 200 ppm, and cooled to 25 ° C;

[0073] (3) The organic peroxide and 0.2% silane coupling agent were added to the biodegradable polyester and mixed uniform to obtain a mixture;

[0074] (4) The silica particles were dried at 100 ° C for 100 min, so that the moisture content of the silica particles was less than 200 ppm and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com