Anti-molten-drop finishing method for polyester

An anti-melting and polyester technology, applied in fiber processing, textile and papermaking, fiber type, etc., can solve the problem that the anti-melting effect of polyester is not ideal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

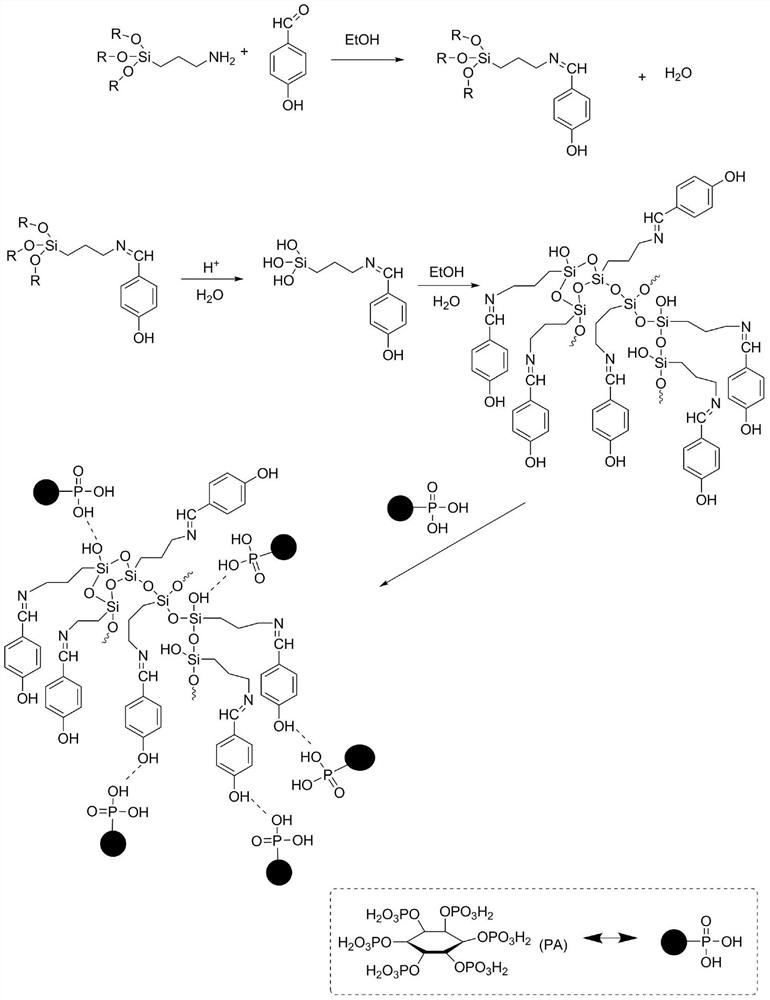

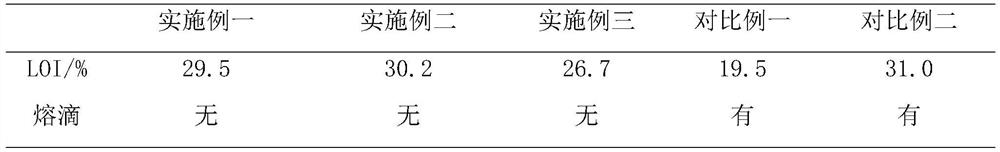

[0037] A kind of anti-droplet finishing method to polyester, comprises the following steps:

[0038] Step (1): preparing a silane precursor containing a Schiff base structure; dissolving 22 parts by mass of 3-aminopropylethoxysilane and 9.8 parts by mass of p-hydroxybenzaldehyde in 90 parts by mass of ethanol, at 80 ° C Select the temperature and react for 4 hours, heat and stir to generate a silane precursor containing a Schiff base structure, distill the reaction product under reduced pressure, remove solvent ethanol and unreacted 3-aminopropylethoxysilane, and obtain a silane containing a Schiff base structure Precursor.

[0039] Step (2): Prepare phytic acid sol working solution; Get 1.5 parts by mass of the silane precursor prepared in step (1), dissolve the silane precursor containing the Schiff base structure prepared in step (1) in a total of ethanol and water In the solvent, wherein the molar ratio of ethanol and water is 6:5, the co-solvent consumption of ethanol an...

Embodiment 2

[0048] A kind of anti-droplet finishing method to polyester, comprises the following steps:

[0049] Step (1): Prepare a silane precursor containing a Schiff base structure; dissolve amino-containing silane and p-hydroxybenzaldehyde in ethanol, heat and stir to generate a silane precursor containing a Schiff base structure, and remove ethanol and unreacted Silane;

[0050] Step (2): prepare phytic acid sol working solution; dissolve the silane precursor containing Schiff base structure prepared in step (1) in the co-solvent of ethanol and water; take phytic acid aqueous solution, take triethylamine as pH Regulator, adjusting the pH of the phytic acid aqueous solution, adding the pH-adjusted phytic acid aqueous solution to the silica sol containing the Schiff base structure, and stirring at room temperature for 1 hour to obtain the prepared phytic acid sol working solution;

[0051] Step (3): Use the phytic acid sol working solution in step (2) to process the polyester flame-r...

Embodiment 3

[0060] A kind of anti-droplet finishing method to polyester, comprises the following steps:

[0061] Step (1): Prepare a silane precursor containing a Schiff base structure; dissolve amino-containing silane and p-hydroxybenzaldehyde in ethanol, heat and stir to generate a silane precursor containing a Schiff base structure, and remove ethanol and unreacted Silane;

[0062] Step (2): prepare phytic acid sol working solution; dissolve the silane precursor containing Schiff base structure prepared in step (1) in the co-solvent of ethanol and water; take phytic acid aqueous solution, use pyridine as pH regulator , adjusting the pH of the phytic acid aqueous solution, adding the pH-adjusted phytic acid aqueous solution to the silica sol containing the Schiff base structure, and stirring at room temperature for 5 hours to obtain the prepared phytic acid sol working solution;

[0063] Step (3): Use the phytic acid sol working solution in step (2) to process the polyester flame-retar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com