Temperature and humidity controllable micron-sized particle turbulence agglomeration experimental device

An experimental device, micron-scale technology, used in monitoring particle agglomeration, measuring device, particle and sedimentation analysis, etc., can solve problems such as luminous flux decline, mechanical failure, output power reduction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

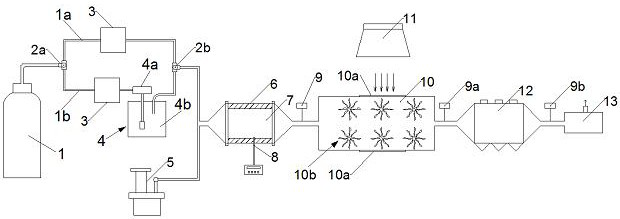

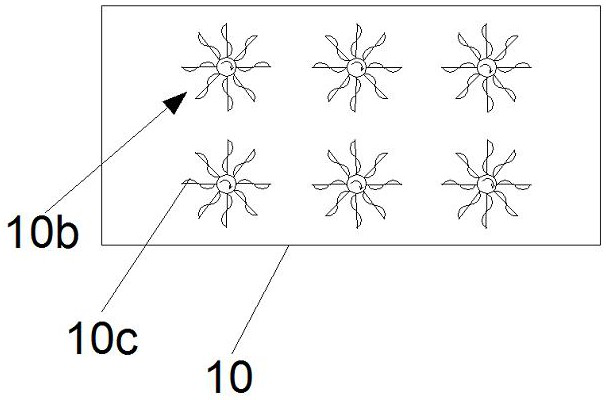

[0022] figure 1 A schematic diagram of an experimental device for turbulent agglomeration of micron-sized particles with controllable temperature and humidity is shown. In the figure, the experimental device for the turbulent agglomeration of micron-sized particles with controllable temperature and humidity includes an air particle generator, an air particle mixing and heating device, a high-speed camera device, an air particle emission processing device, and a turbulent collision agglomeration device. The gas particle generating device includes a gas cylinder 1, a mass flow meter 3, a humidifier 4 and a particle generator 5. The humidifier 4 includes a sprayer 4a and a mixer 4b. The gas cylinder 1 passes through the first three-way valve 2a through the first branch pipe 1a, One flowmeter 3 is connected to the gas mixer 4b, the gas cylinder 1 passes through the first three-way valve 2a through the second branch pipe 1b, and the other flowmeter 3 is connected to the sprayer 4a,...

Embodiment 2

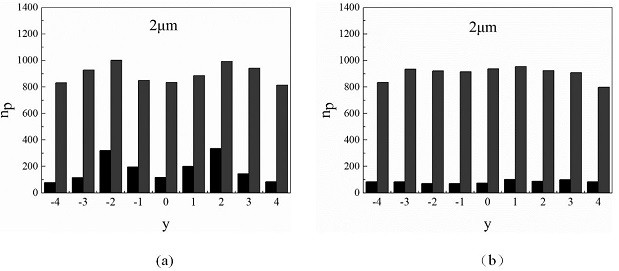

[0037] Set the size of the turbulent flow agglomerator to be 100mm×40mm×8mm in length×width×height, the diameter of the spoiler impeller is 2mm, the vertical distance is 8mm, and the left and right distance is 10mm. -EDEM coupling is used for numerical simulation calculation verification, the gas flow rate is set to 7.5m / s, and the spoiler impeller is driven by airflow. image 3 It shows the distribution diagram of 2μm particle number and agglomeration number in different turbulence areas. In the figure, a is the distribution diagram of 2μm particle number and agglomeration number passing through the turbulence agglomerator, b is the 2μm particle number and agglomeration number without disturbing flow The distribution map of , black represents the number of particles that have agglomerated, and gray represents the number of particles in this area. from image 3 It can be seen that after the disturbance of the turbulent collision and agglomeration device, the number of 2 μm pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com