Carbon-coated cobalt composite nano wave-absorbing material and preparation method thereof

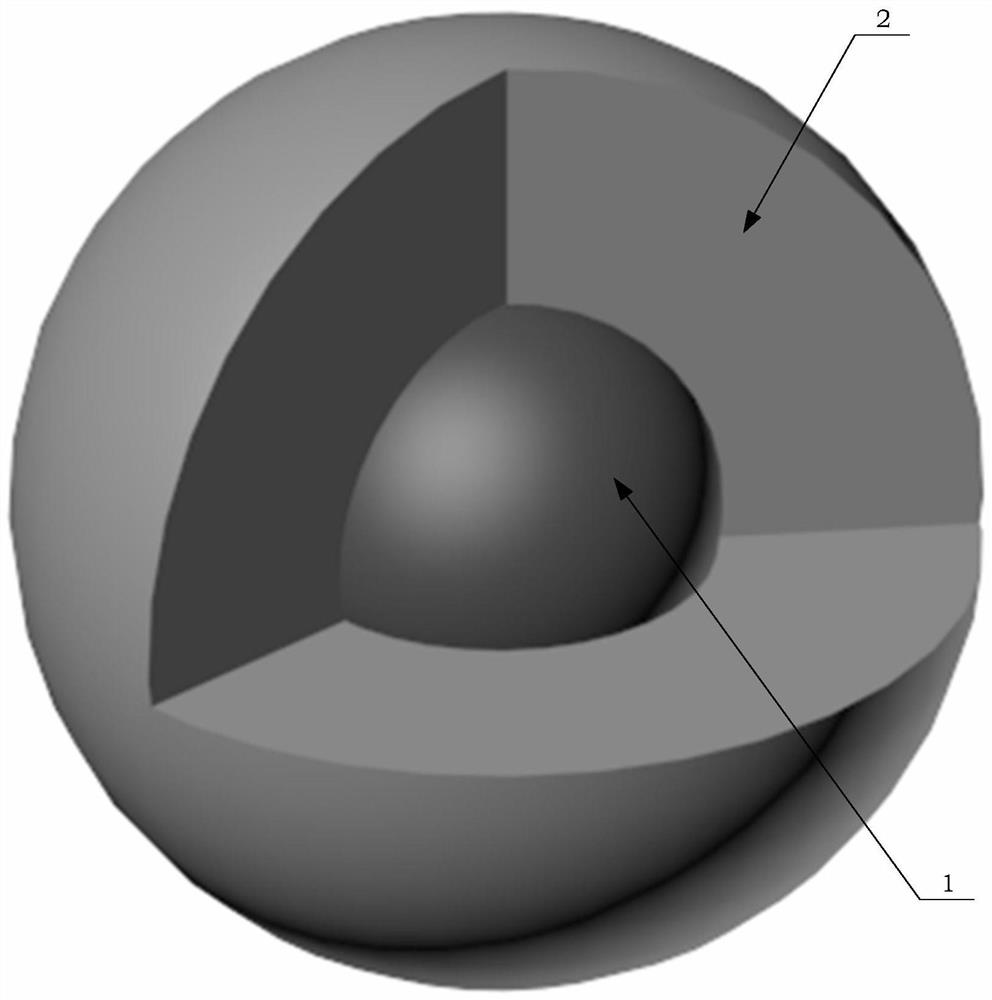

A composite nano-particle and nano-particle technology, applied in the field of carbon-coated cobalt composite nano-wave absorbing materials, can solve the problems of unsatisfactory electromagnetic wave absorption performance of composite materials, easy agglomeration of magnetic metal cobalt particles, poor impedance matching, etc., and achieve excellent electromagnetic waves. The effect of absorption performance, low cost, simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] The method for preparing the carbon-coated cobalt composite nano wave-absorbing material of the present invention comprises the following steps:

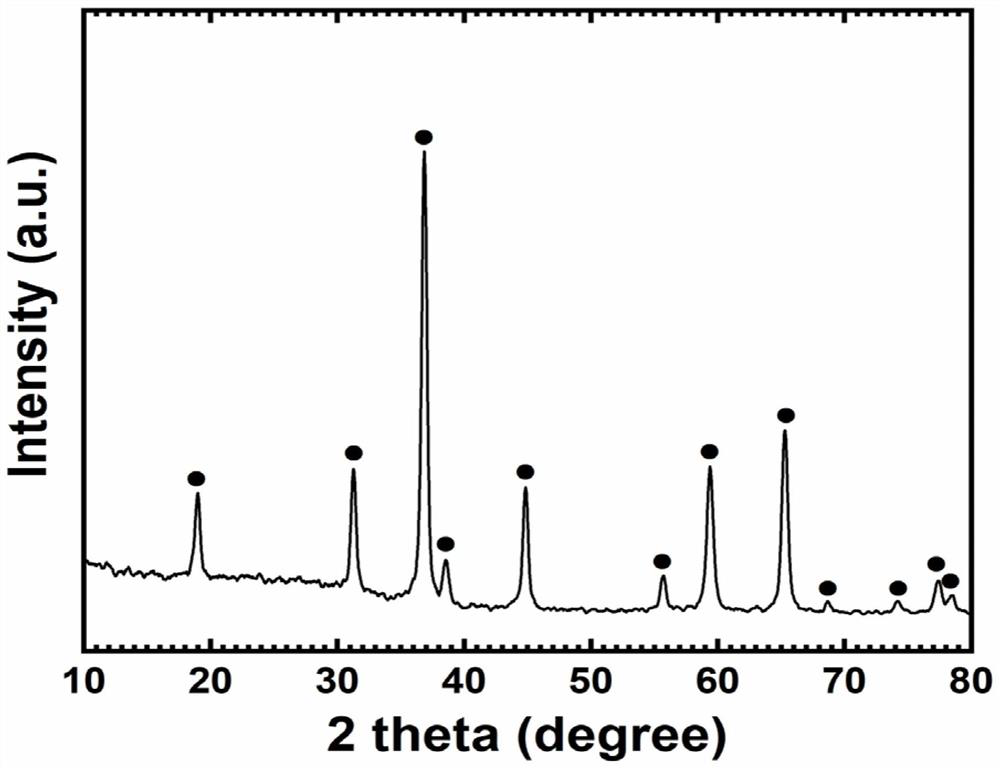

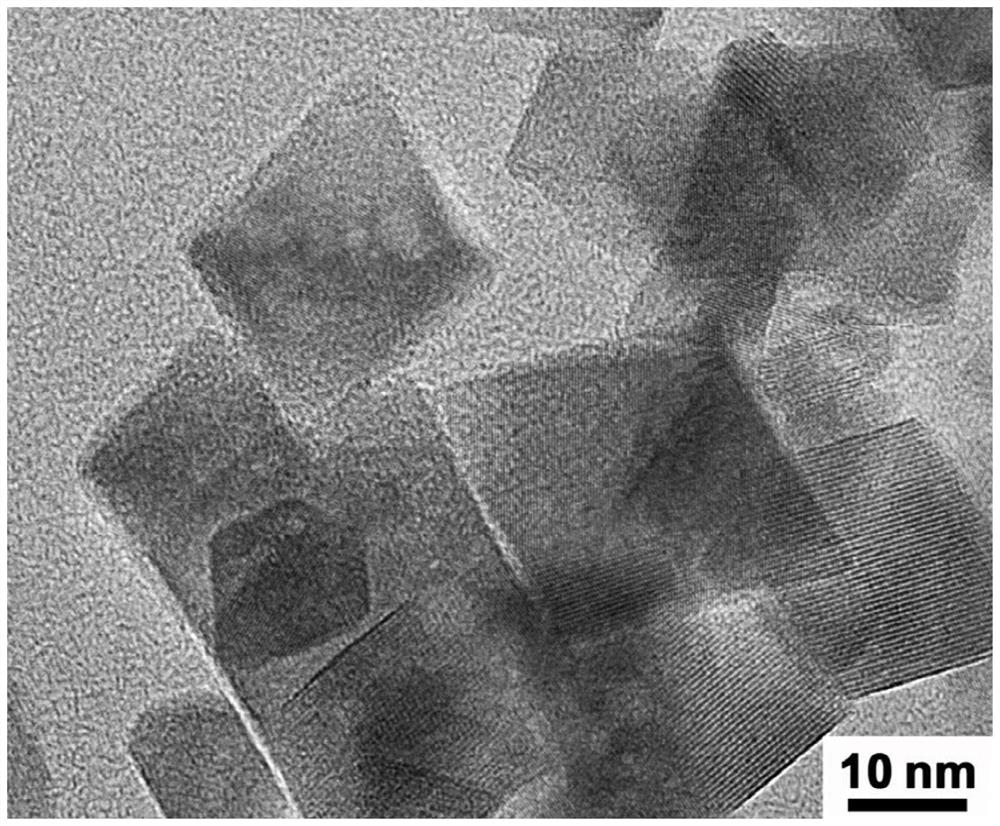

[0060] Step 1, preparation of Co by nitrate pyrolysis 3 o 4 nanoparticles;

[0061] Step 11, 0.02mol of cobalt nitrate hexahydrate (Co(NO 3 ) 2 ·6H 2 O) dissolved in 100 mL of deionized water; adding 40 mL of ammonia water (25-28%) to adjust the pH of the solution to 11-12, and stirring the solution for 120 min to obtain a mixed solution;

[0062] Ultrasonic conditions: ultrasonic frequency 40kHz, ultrasonic treatment time 30min;

[0063] Step 12, put the mixed solution in a drying oven at 180°C and keep the temperature constant for 8 hours to prepare Co 3 o 4 Powder;

[0064] Step 13, deionized water for Co 3 o 4 The powder was washed repeatedly to obtain pure Co 3 o 4 Powder;

[0065] Step 14, the pure Co 3 o 4 The powder was dried in a vacuum oven at 50°C to 80°C for 12 hours to obtain Co 3 o 4 nanoparticl...

Embodiment 2

[0080] The method for preparing the carbon-coated cobalt composite nano wave-absorbing material of the present invention comprises the following steps:

[0081] Step 1, preparation of Co by nitrate pyrolysis 3 o 4 nanoparticles;

[0082] Step 11, 0.01mol of cobalt nitrate hexahydrate (Co(NO 3 ) 2 ·6H 2 O) dissolved in 50mL of deionized water; add 20mL of ammonia water (25-28%) to adjust the pH of the solution to 11-12, and stir the solution for 120min to prepare a mixed solution;

[0083] Ultrasonic conditions: ultrasonic frequency 40kHz, ultrasonic treatment time 30min;

[0084] Step 12, put the mixed solution in a drying oven at 180°C and keep the temperature constant for 8 hours to prepare Co 3 o 4 Powder;

[0085] Step 13, deionized water for Co 3 o 4 The powder was washed repeatedly to obtain pure Co 3 o 4 Powder;

[0086] Step 14, the pure Co 3 o 4 The powder was dried in a vacuum oven at 60°C for 12 hours to obtain Co 3 o 4 nanoparticles.

[0087] Step...

Embodiment 3

[0097] The method for preparing the carbon-coated cobalt composite nano wave-absorbing material of the present invention comprises the following steps:

[0098] Step 1, preparation of Co by nitrate pyrolysis 3 o 4 nanoparticles;

[0099] Step 11, 0.02mol of cobalt nitrate hexahydrate (Co(NO 3 ) 2 ·6H 2 O) be dissolved in 100mL of deionized water; add 40mL of ammonia water (25-28%) to adjust the pH of the solution to 11-12, and stir the solution for 120min; prepare a mixed solution;

[0100] Ultrasonic conditions: ultrasonic frequency 40kHz, ultrasonic treatment time 30min;

[0101] Step 12, put the mixed solution in a drying oven at 180°C and keep the temperature constant for 8 hours to prepare Co 3 o 4 Powder;

[0102] Step 13, deionized water for Co 3 o 4 The powder was washed repeatedly to obtain pure Co 3 o 4 Powder;

[0103] Step 14, the pure Co 3 o 4 The powder was dried in a vacuum oven at 60°C for 12 hours to obtain Co 3 o 4 nanoparticles.

[0104] St...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com